Method of measuring large deformation resistant pipeline steel SH-CCTA curve

A SH-CCT, anti-large deformation technology, applied in the preparation of test samples, thermal expansion coefficient of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment the present invention is described in further detail.

[0022] The embodiment of the present invention is given by taking pipeline steel X70 as an example. The specific steps are:

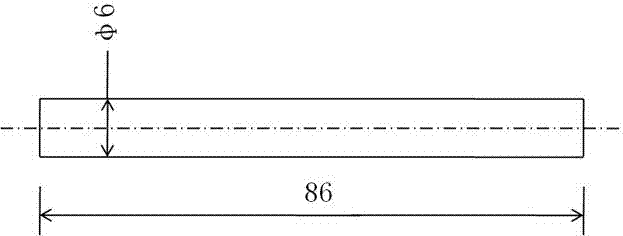

[0023] (1) First, use a round bar sample of φ6×86mm to measure the solid phase transition point of X70 grade pipeline steel. The sample was heated to 500°C for 30 minutes, and then slowly heated to 1000°C at a rate of 0.05°C / s, and the Ac1 and Ac3 of the material were determined according to the measured temperature rise thermal expansion curve.

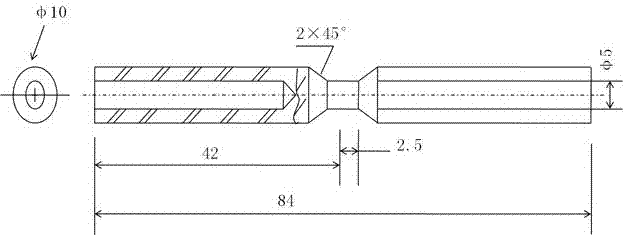

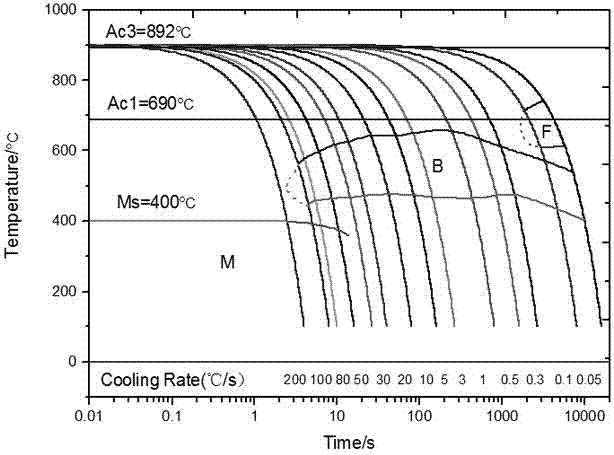

[0024] (2) The measurement process of the SH-CCT curve of X70 pipeline steel is as follows: heat the sample at a rate of 150 °C / s to a peak temperature of 1300 °C, and hold for 1 s. The cooling time from 1300°C to 900°C is fixed at 9s. Then at 0.05°C / s, 0.1°C / s, 0.3°C / s, 0.5°C / s, 1°C / s, 3°C / s, 5°C / s, 10°C / s, 20°C / s, 30°C / s, 50°C / s, 80°C / s, 100°C / s and 200°C / s with a series of different cooling rates to cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com