Application of heteropoly acid and lewis acid as catalyst to degradation of thermosetting resin

A technology of Lewis acid and heteropoly acid, applied in the field of heteropoly acid and Lewis acid, to achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

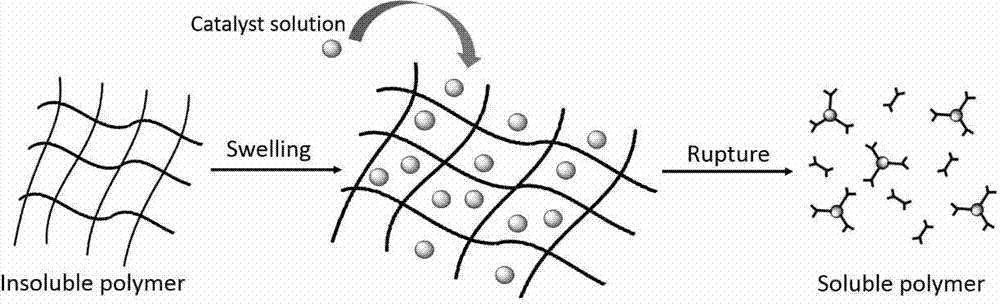

Method used

Image

Examples

Embodiment Construction

[0021] (1) Example of chemical degradation using a heteropolyacid catalyst system

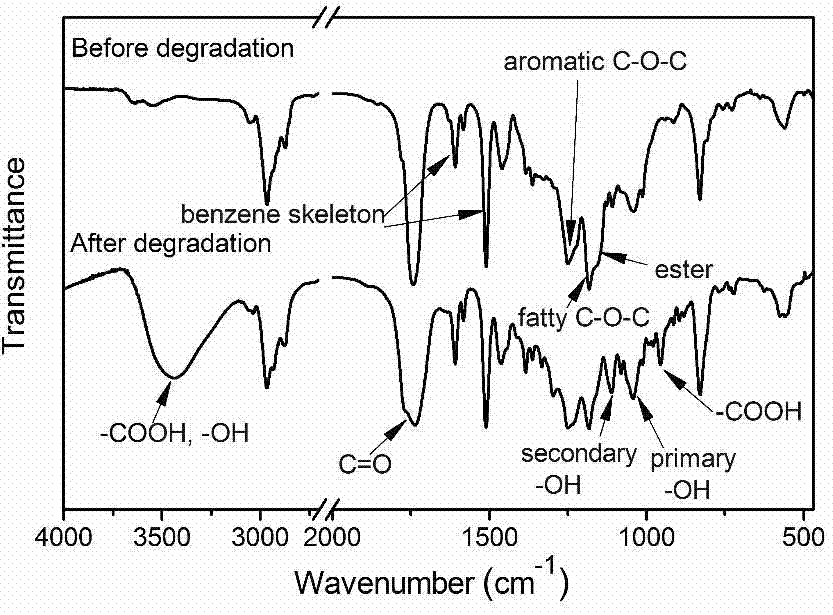

[0022] The degradation reaction is carried out in a pressure reactor. Dissolve 0.2g of phosphotungstic acid in 20.0g of water. The resulting solution and 6.0 g of epoxy-anhydride cured product were charged into the pressure reactor. The temperature of the reactor was raised to the predetermined temperature and reacted for 5 hours. After the reaction, the reactor was cooled to room temperature, and the reaction solution was filtered. The degraded polymer was washed with water to remove residual catalyst, and then dried in a vacuum oven at 80 °C. The final degradation product was light yellow powder. The infrared analysis results before and after resin degradation are as follows: figure 2 shown.

[0023] (2) Example of chemical degradation using a Lewis acid catalyst system

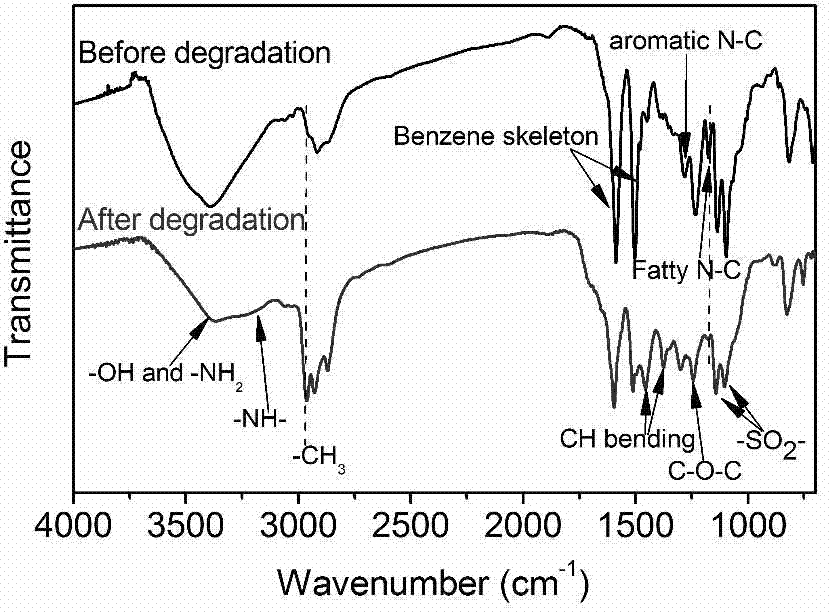

[0024] The degradation reaction is carried out in a pressure reactor. The ZnCl2 / ethanol solution and the epoxy-am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com