Concrete reserved hole formwork installing method

A technology of reserved holes and installation methods, which is applied in the direction of formwork/formwork/work frame, building structure, and on-site preparation of building components, which can solve the problems of inconvenient installation of reserved hole formwork and achieve formwork setting Simple, the effect of reducing template loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

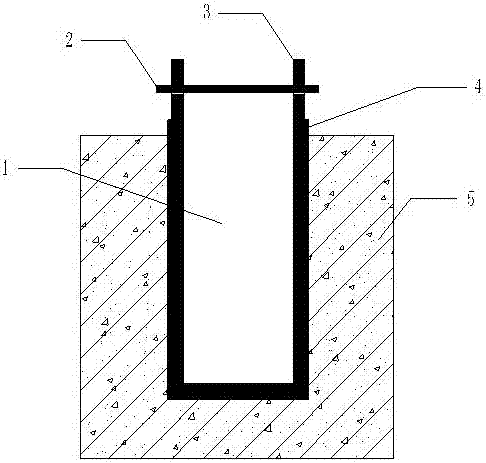

[0031] see now figure 1 , figure 1 It is a schematic diagram of template installation in the embodiment of the present invention.

[0032] The installation method of the concrete reserved hole formwork of the present invention comprises the following steps:

[0033] a. Carry out formwork processing and on-site laying-out work at the same time according to the hole size and center line position reserved for the concrete in the drawing; the formwork is a 12mm thick nine-plywood.

[0034] b. Under the premise of meeting the specification requirements, process the reserved holes so that the top section size is larger than the bottom section size.

[0035] c. The height of the template is 20cm higher than the height of the reserved hole, and the holes are symmetrically drilled on the template 10cm higher than the reserved hole.

[0036] d. After the template processing and assembly are completed, the outer side of the foam board covered with pearl cotton with a thickness of 6mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com