Continuous casting tundish moulding bed combustor

A continuous casting tundish and burner technology, which is applied to air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem of poor baking efficiency of the tundish heat insulation layer, insufficient temperature of the tundish wall, and reduced service life and other problems, to achieve the effect of convenient unmanned ignition operation, improved service life, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

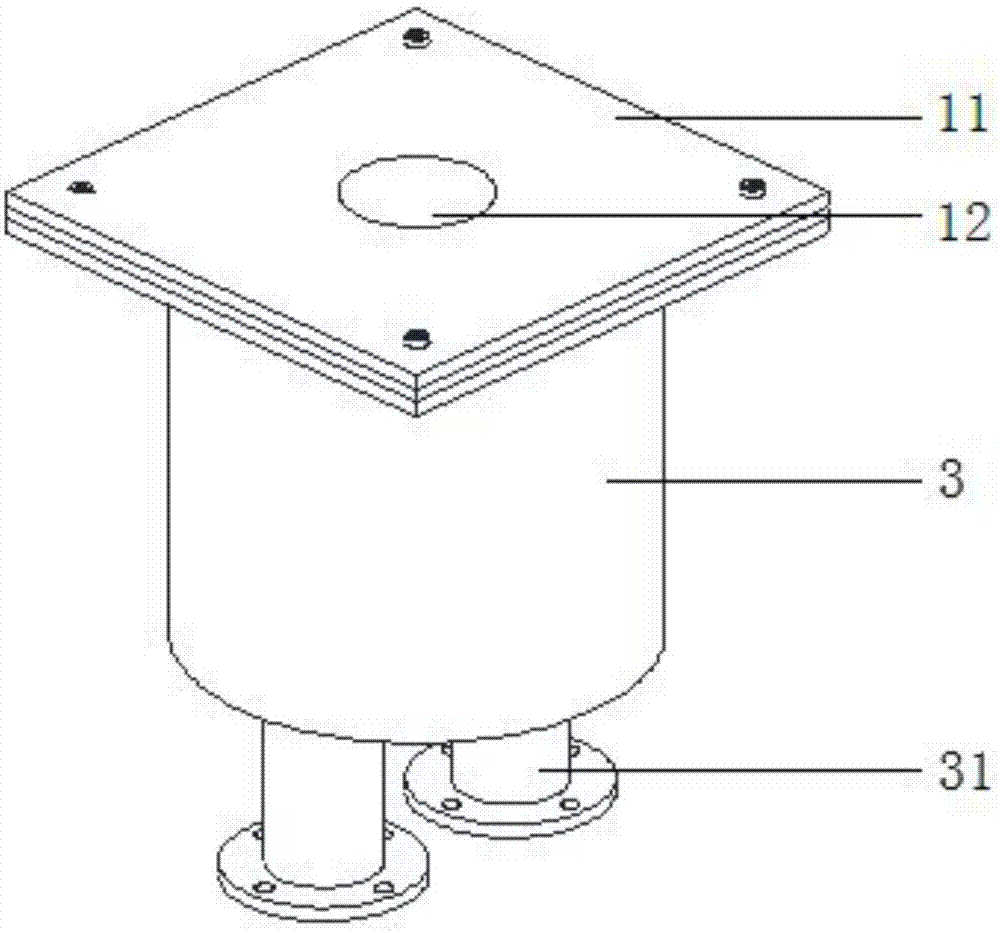

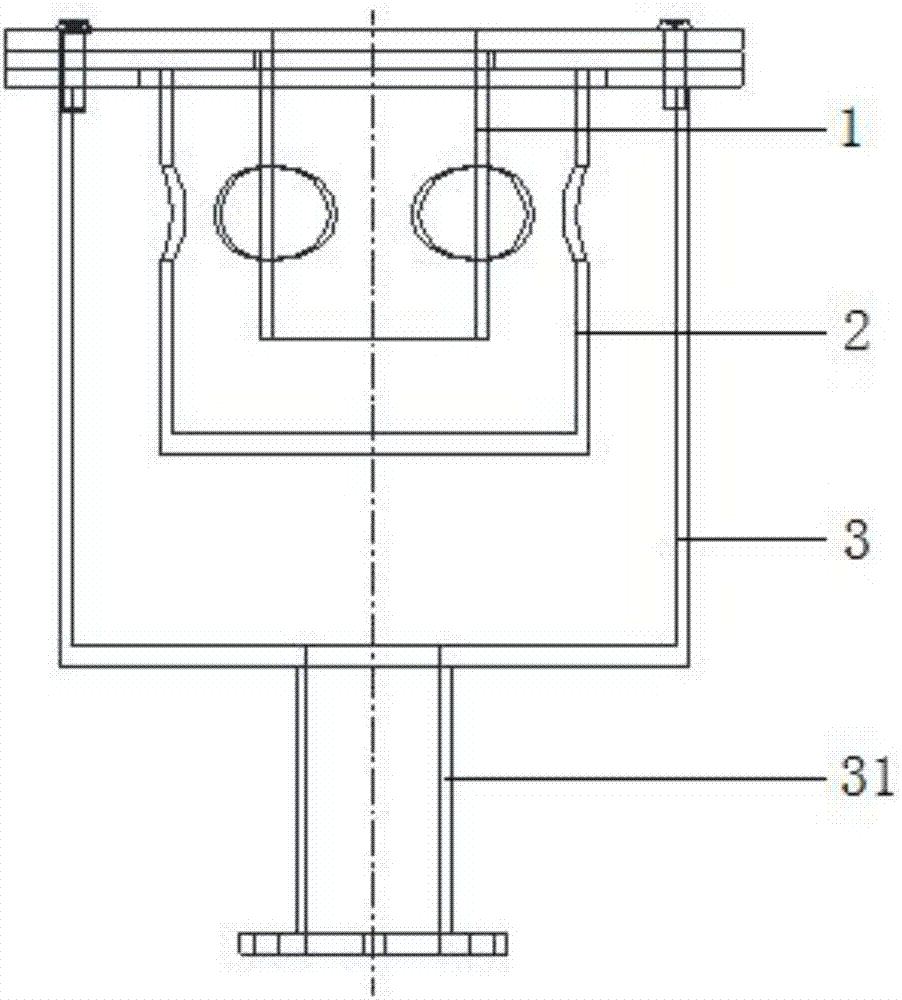

[0038] In conjunction with the accompanying drawings, Embodiment 1 of the present invention: first assemble the combustion chamber, the inner heat transfer chamber and the outer heat transfer chamber, and then seal the whole with the tundish tire mold; The holes are introduced into the combustion chamber and ignited for combustion, and the hot air in the combustion chamber enters the inner heat transfer chamber through the bottom of the combustion chamber, and is transported to the outer heat transfer chamber through the heat conduction holes, and then transfers heat to the middle through the heating tube at the bottom of the outer heat transfer chamber The inside of the tire mold is evenly heated as a whole, the inside of the tundish tire mold forms convection with the continuous input of hot air, and the cold air and exhaust gas after combustion are discharged through the exhaust pipe around the top of the tundish tire mold.

[0039] In conjunction with the accompanying drawi...

Embodiment 3

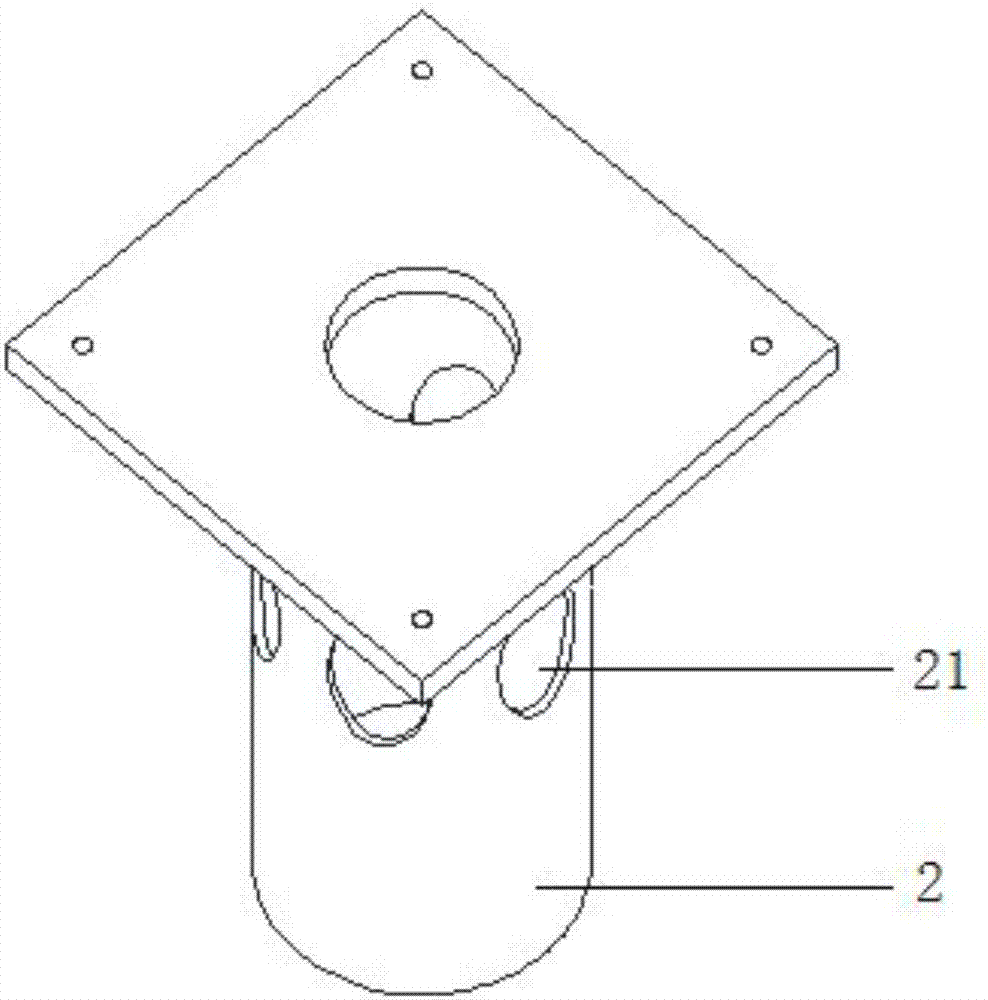

[0045] Working principle of embodiment three: the flame is sprayed in from the jet hole 12, and after rushing out from the lower end of the cylinder of the combustion chamber 1, it impacts on the flame impingement plate 16. In the cavity of the heat transfer chamber 3, the compressed air tube group 9 evenly distributed in a ring shape is evenly heated, the compressed air enters from the intake tube 10, and after being heated in the compressed air tube group 9, it rushes out from the outlet tube 14 at the lower end, Because the flow velocity of the hot compressed air rushed out of the air outlet pipe 14 is very fast, and the combustion gas in the outer heat transfer chamber 3 is ejected from the heating pipe 31 at a slow speed, and because the port surface of the air outlet pipe 14 is located inside the heating pipe 31, it is When the heated compressed air comes out, it can form a negative air pressure between the outlet pipe 14 and the cavity of the heating pipe 31, forming a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com