Valve debugging and diagnosis integration device and analysis method

An analysis method and technology of integrators, applied in the testing of instruments, mechanical parts, control/regulating systems, etc., can solve the problems of automatic, comprehensive and quantitative analysis of valve operation performance, etc., which is conducive to safe production and improves safety. and quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

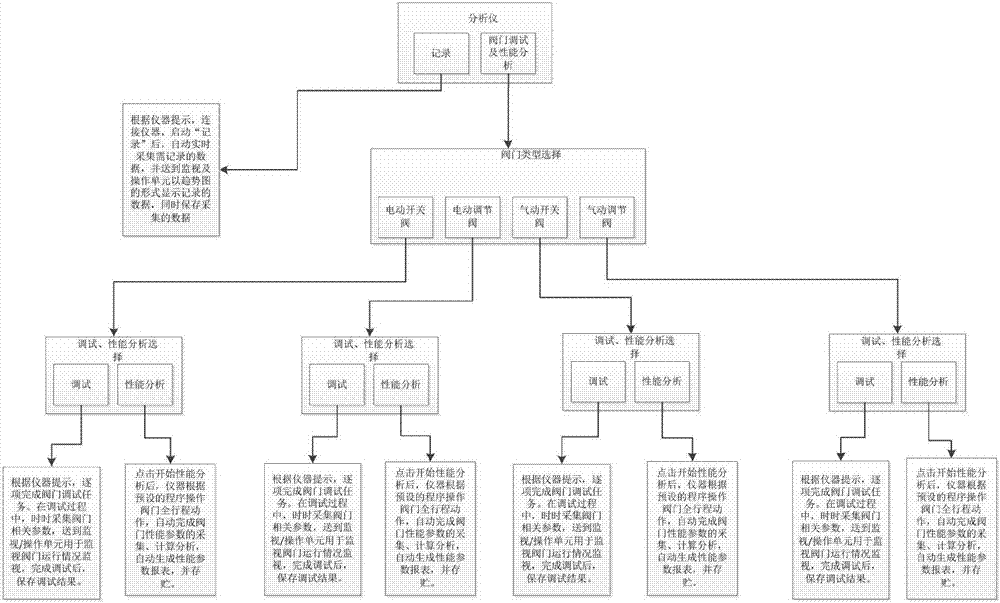

[0044] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

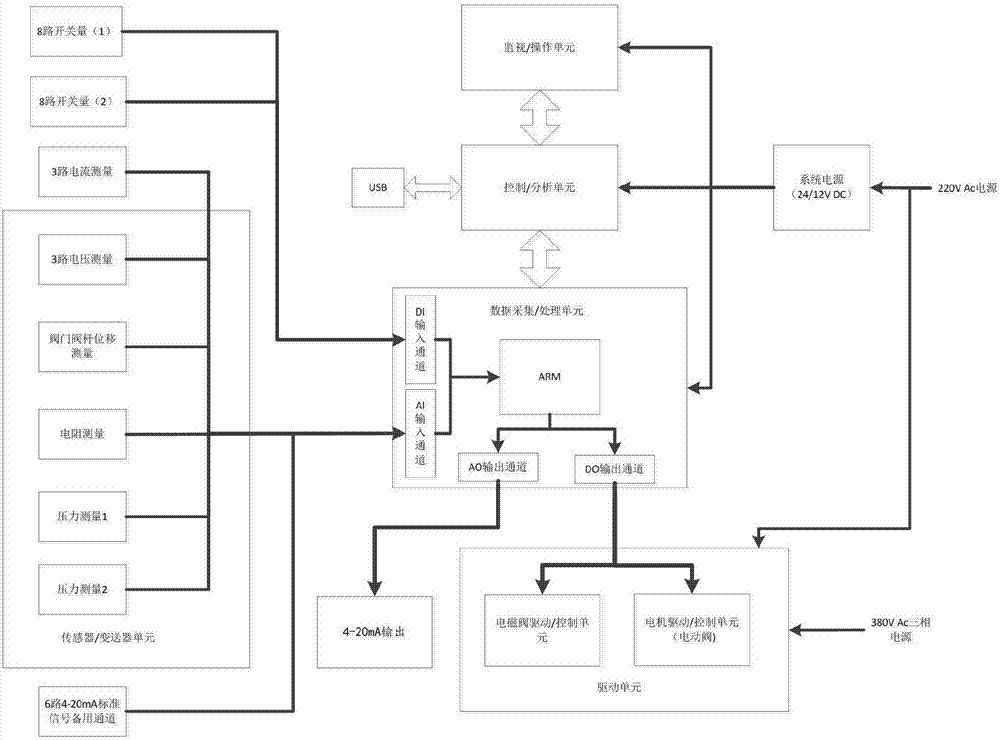

[0045] see figure 1 The comprehensive instrument for valve debugging and diagnosis provided by the present invention includes a sensor and transmitter unit, a data acquisition and processing unit, a control and analysis unit, a monitoring and operation unit, a drive unit, and a system power supply, wherein,

[0046] Sensor and transmitter unit: used to measure valve actuator cylinder air pressure, control air pressure, valve stem displacement, motor voltage and current, and convert them into corresponding electrical signals and send them to the AI input channel of the corresponding data acquisition and processing unit .

[0047] There are 16 AI channels, which are used to constantly monitor the status of valve travel switches, limit switches and torque switches. The specific distribution and functions of the 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com