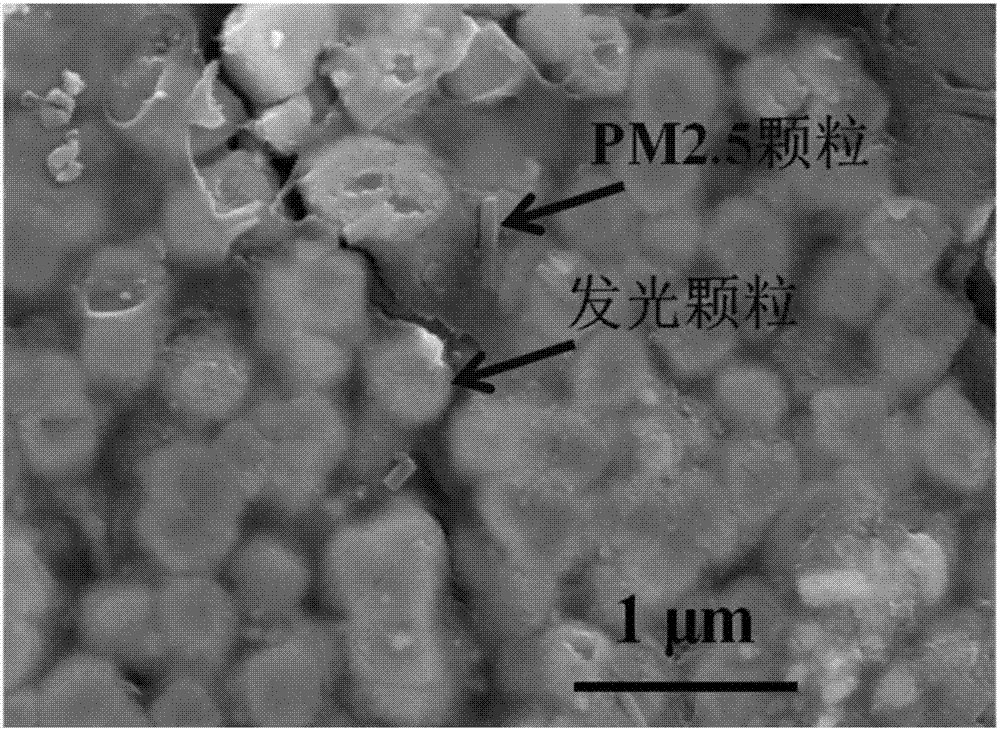

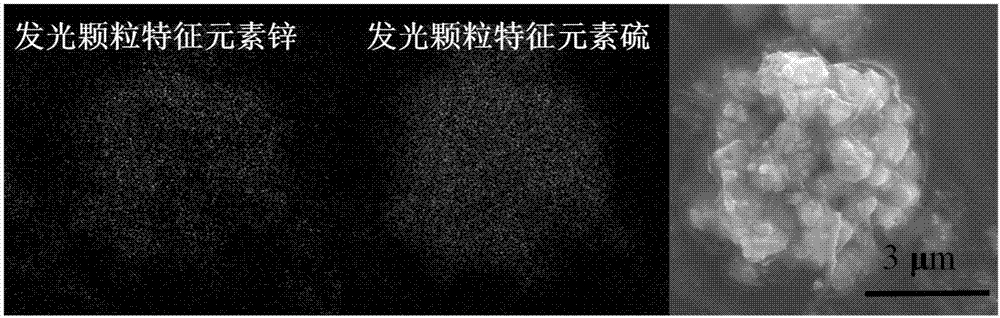

Traceable PM2.5 granular composite material and its preparation method

A technology of PM2.5 and composite materials, which is applied in the analysis of materials, particle suspension analysis, suspension and porous material analysis, etc., can solve the problem of complex pathogenicity and toxicity of PM2.5 haze particles, complex preparation of model materials, The simulation degree is not high, and the effects of easy promotion, simple preparation method and high luminous efficiency are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

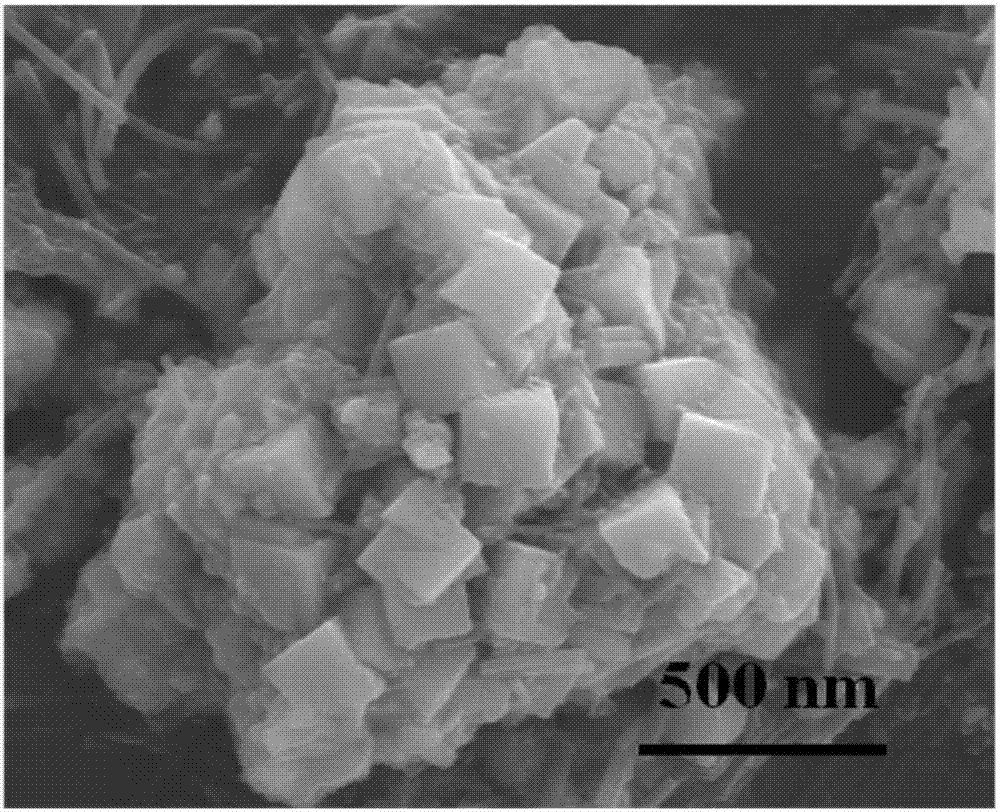

Embodiment 1

[0040] 1) Soak the glass fiber filter membrane that collected PM2.5 haze particles with the atmospheric collector (MH1200, atmospheric particle sampler, Yancheng Tianyue Instrument Co., Ltd.) into ethanol for 12 hours, then take out the filter membrane, and dissolve the The ethanol solution with PM2.5 particles was placed in a vacuum freeze-drying oven (Scientz-ND, freeze-drying machine, Ningbo Xinzhi Biotechnology Co., Ltd.), set the freezing temperature to -200 ° C, freeze-dried for 50 hours, and fully evaporated and dried to obtain Treated PM2.5 particles;

[0041] 2) ZnGa prepared by solid-state method 2 o 4 : Cr 3+(According to the patent CN201510650991.2) after stirring and sonicating, dissolve it into water, let it stand for 24 hours, take the suspension, and use a centrifuge to centrifuge at a high speed at 10000rpm to obtain near-infrared super long Afterglow ZnGa 2 o 4 : Cr 3+ nanoparticles.

[0042] 3) Take ZnGa 2 o 4 : Cr 3+ Dissolve 0.02g of nanoparticle...

Embodiment 2

[0046] Using the same method as in Example 1, using polyvinyl alcohol with a mass fraction of 5% to replace the cyclodextrin used, a traceable PM2.5 particulate composite material was prepared.

[0047] The traceable PM2.5 particle composite material prepared in this example was used to characterize the properties of the sample, and the test results were similar to Example 1.

Embodiment 3

[0049] Adopt the same method of embodiment 1, use near-infrared long afterglow luminescent material Zn 3 Ga 2 Ge 2 o 10 :Cr 3+ (According to the patent CN103215041A) is compounded with PM2.5 particles to obtain a traceable PM2.5 particle composite material.

[0050] The traceable PM2.5 particle composite material prepared in this example was used to characterize the properties of the sample. The test results were similar to those in Example 1, and the traceable PM2.5 particle composite material had better long afterglow performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com