TVS (Transient Voltage Suppressor) with deep trench isolation structure and manufacturing method thereof

A technology of isolation structure and manufacturing method, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problem of transient voltage suppressor surge capacity reduction, unfavorable capacitive effect reducing device size, and leucorrhea effect. Breakthrough voltage drop and other problems, to achieve the effect of reduced size, high resistance to process fluctuations, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

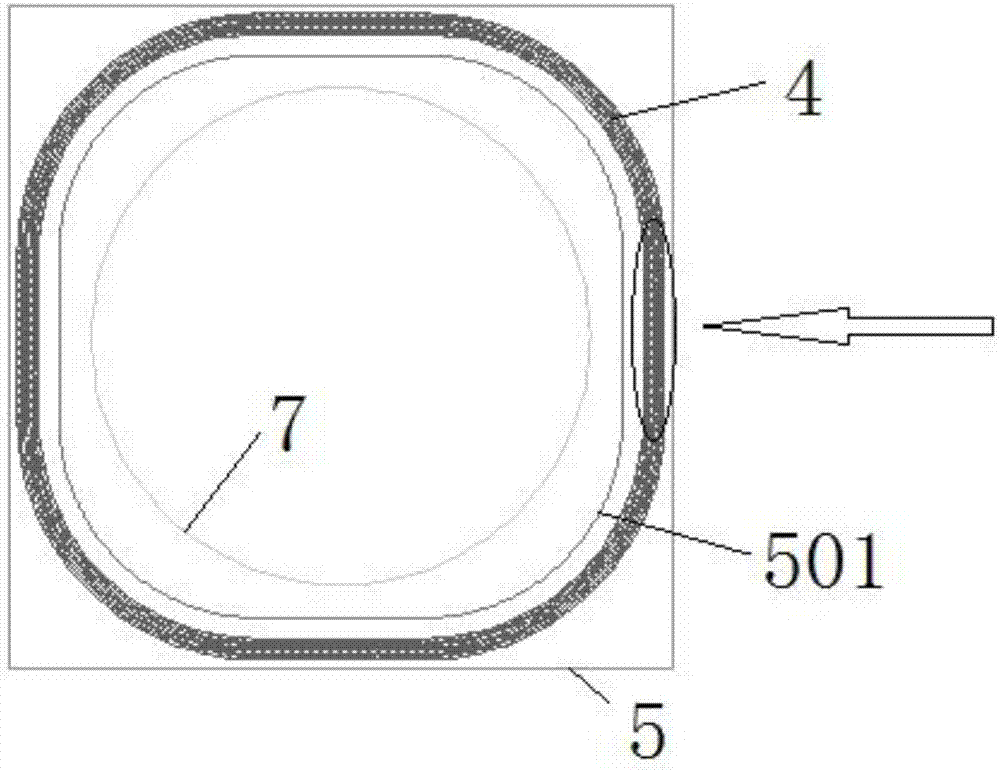

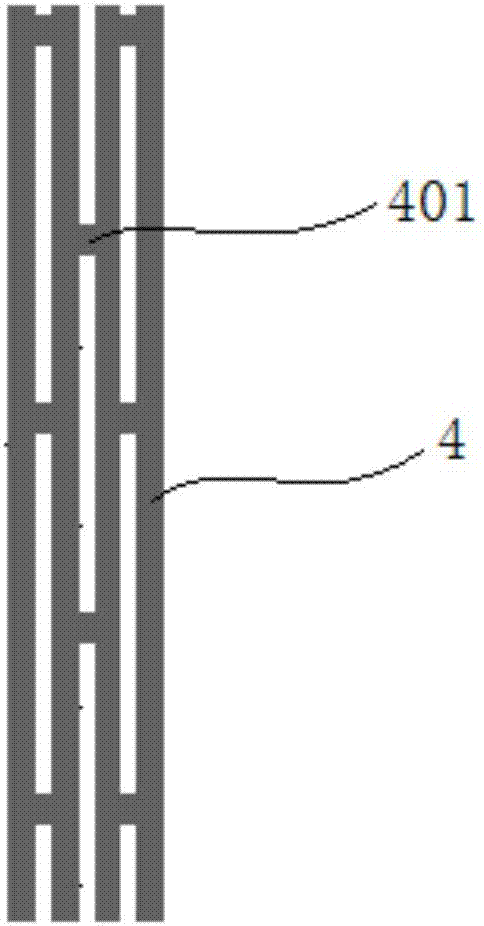

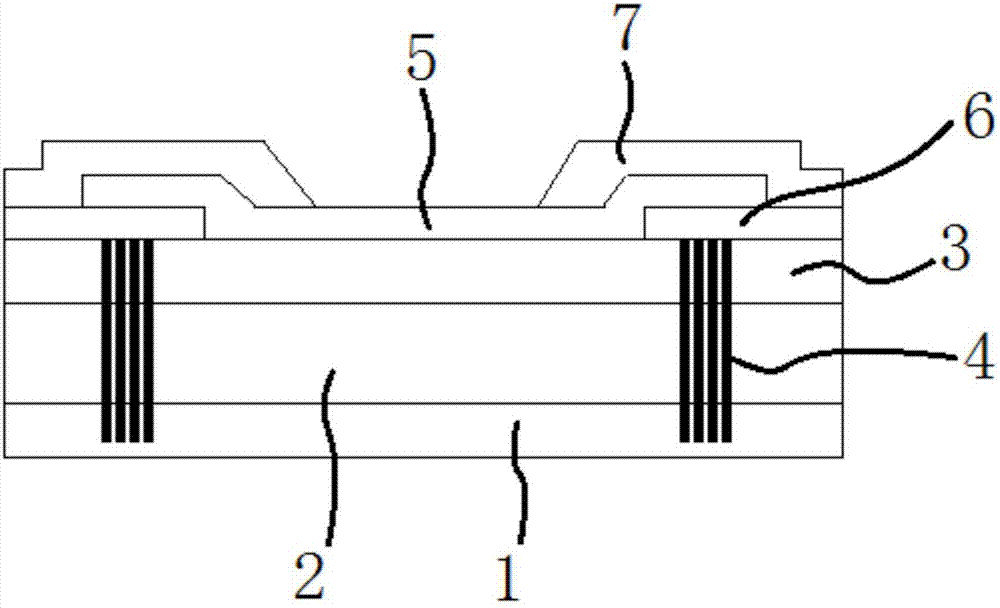

[0049] like figure 1 , 2 As shown in and 3, the TVS with deep trench isolation structure of the present invention includes a substrate 1 and an epitaxial layer 2 opposite to the type of the substrate. The epitaxial layer has a doped layer 3 of the same type as the substrate, and the periphery of the TVS is provided with The annular deep groove 4 is filled with an insulating medium, and a contact hole 501 is opened on the doped layer inside the deep groove, and a metal is drawn out to make the first electrode 5. The doped layer is covered with an interlayer dielectric 6 to connect the first electrode with the deep Groove isolation, a passivation layer 7 is provided on the first electrode, and a hole for the first electrode is op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com