Automatic slurry filtering system capable of efficiently treating soybean milk

A technology for filtering pulp and soy milk, which is applied in the direction of mobile filter element filter, filtration separation, filtration loop, etc. cloth, low power consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific embodiments. The purpose of the following words is to illustrate the present invention, rather than limit the protection scope of the present invention.

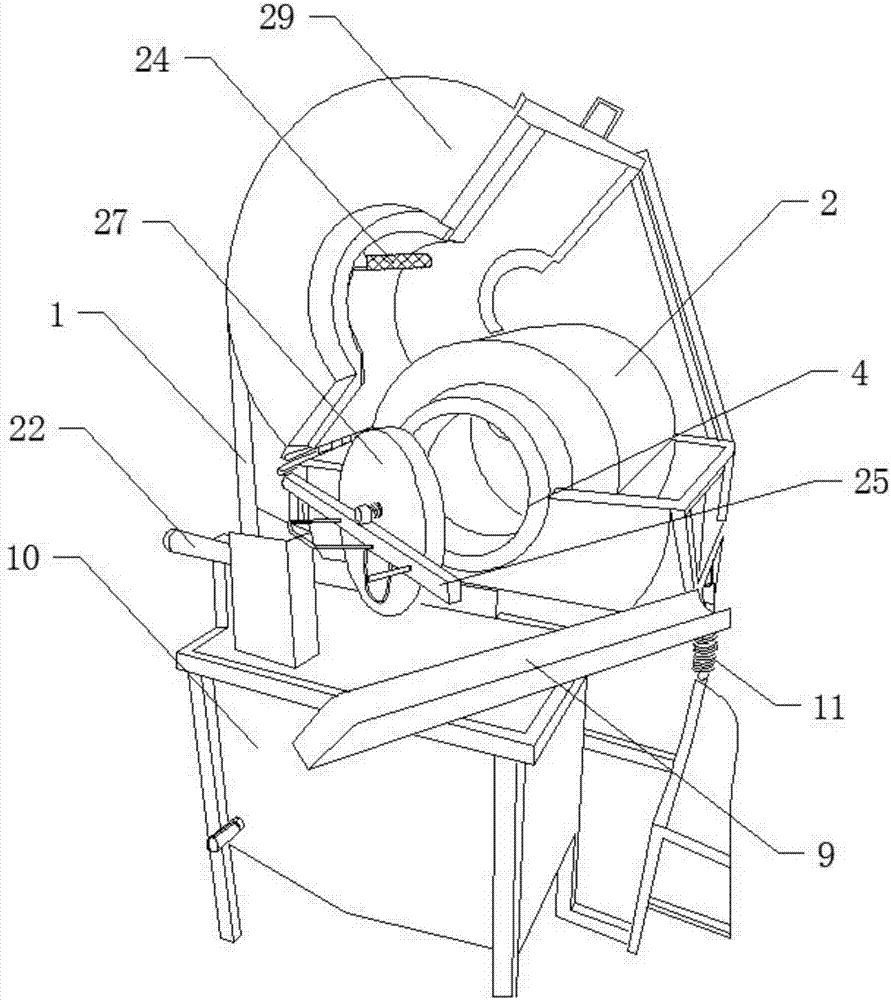

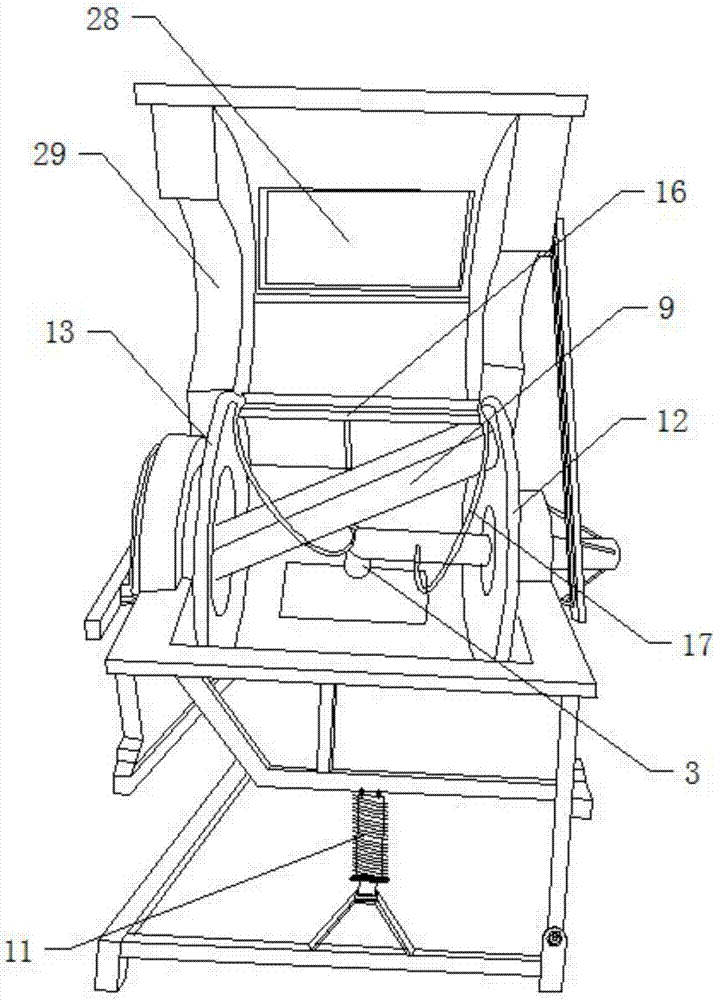

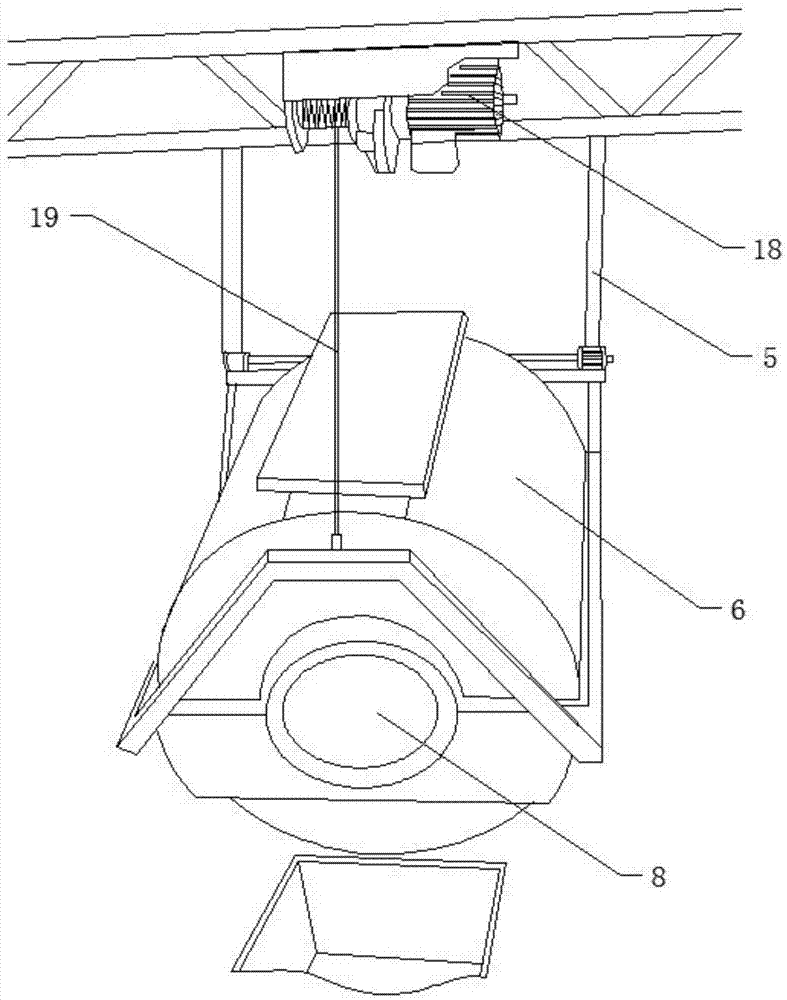

[0026] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention can be implemented in the following manner, an automatic slurry filtration system that can efficiently process soybean milk, including a first slurry filter, a second slurry filter positioned above the first slurry filter, a transfer container 10 and a Fix the support 5 of the first pulp filter machine and the second pulp filter machine, the first filter pulp machine includes a first body 1, a first filter cartridge 2 that is rotatably arranged in the first body 1, and the first filter cartridge One end of 2 extends into a first slurry inlet pipe 3, one end of the first slurry inlet pipe 3 is located in the middle of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com