Water filter element with antibacterial effect

A technology of water filtration and filter element, which is applied in the field of water filtration filter element, can solve the problems of unsatisfactory and single organic matter filtration effect, achieve good effect, improve filtration efficiency, and high-efficiency filtration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

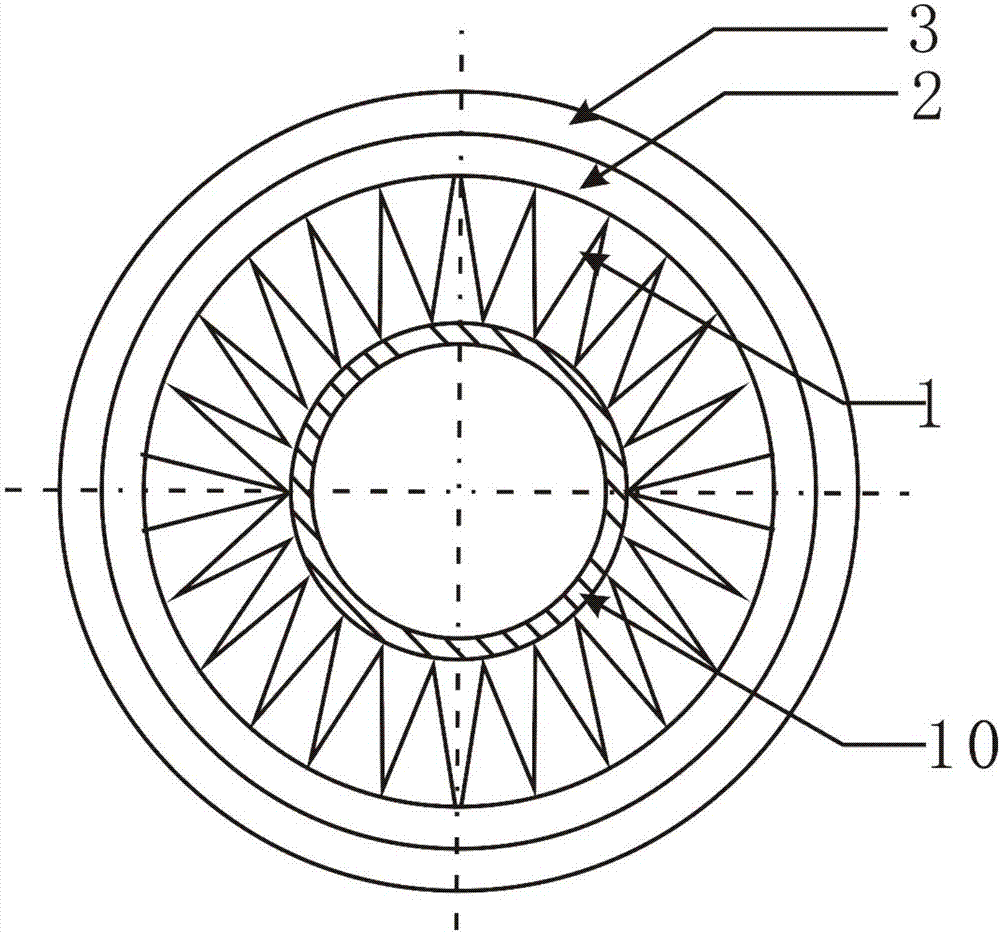

Image

Examples

Embodiment 1

[0036] 1) Prepare the precursor spinning solution: weigh 7ml of absolute ethanol and 3ml of glacial acetic acid in a conical flask as a solvent, then weigh 0.6g of polyvinyl pyrrolidone and add it to the above mixed solution, and stir evenly at room temperature , then slowly add 3.0g of butyl titanate, continue to stir, then weigh 1.2g of diisopropyl azodicarboxylate (foaming agent) and continue to stir, then, add an appropriate amount of WCl 6 , AgNO 3 , ferric chloride, continue to stir for 2h, obtain the precursor spinning solution;

[0037] 2) Electrospinning: put 6ml of the precursor spinning liquid into a plastic needle tube after standing still, and put it on a micro-injection pump, and set the injection speed to 1ml / h. The metal needle is used as the electrospinning anode, and the wire mesh is used as the cathode of the receiving material. The distance between the anode and the cathode is 20cm. Electrospinning is performed at a high voltage of 20kV, and the solid orga...

Embodiment 2

[0040] 1) Prepare the precursor spinning solution: weigh 7ml of absolute ethanol and 3ml of glacial acetic acid in a conical flask as a solvent, then weigh 0.6g of polyvinyl pyrrolidone and add it to the above mixed solution, and stir evenly at room temperature , then slowly add 3.0g of butyl titanate, continue to stir, then weigh 1.2g of diisopropyl azodicarboxylate (foaming agent) and continue to stir, then, add an appropriate amount of WCl 6 , AgNO 3 , ferric chloride, continue to stir for 2h, obtain the precursor spinning solution;

[0041] 2) Electrospinning: put 6ml of the precursor spinning liquid into a plastic needle tube after standing still, and put it on a micro-injection pump, and set the injection speed to 1ml / h. The metal needle is used as the electrospinning anode, and the wire mesh is used as the cathode of the receiving material. The distance between the anode and the cathode is 20cm. Electrospinning is performed at a high voltage of 20kV, and the solid orga...

Embodiment 3

[0044] 1) Prepare the precursor spinning solution: weigh 7ml of absolute ethanol and 3ml of glacial acetic acid in a conical flask as a solvent, then weigh 0.6g of polyvinyl pyrrolidone and add it to the above mixed solution, and stir evenly at room temperature , then slowly add 3.0g of butyl titanate, continue to stir, then weigh 1.2g of diisopropyl azodicarboxylate (foaming agent) and continue to stir, then, add an appropriate amount of WCl 6 , AgNO 3 , ferric chloride, continue to stir for 2h, obtain the precursor spinning solution;

[0045] 2) Electrospinning: put 6ml of the precursor spinning liquid into a plastic needle tube after standing still, and put it on a micro-injection pump, and set the injection speed to 1ml / h. The metal needle is used as the electrospinning anode, and the wire mesh is used as the cathode of the receiving material. The distance between the anode and the cathode is 20cm. Electrospinning is performed at a high voltage of 20kV, and the solid orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com