NMP filter

A filter and waste gas pipe technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of reduced economic benefits, increased costs, waste of resources, etc., to prolong residence time, increase contact time, exhaust gas Discharge without pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

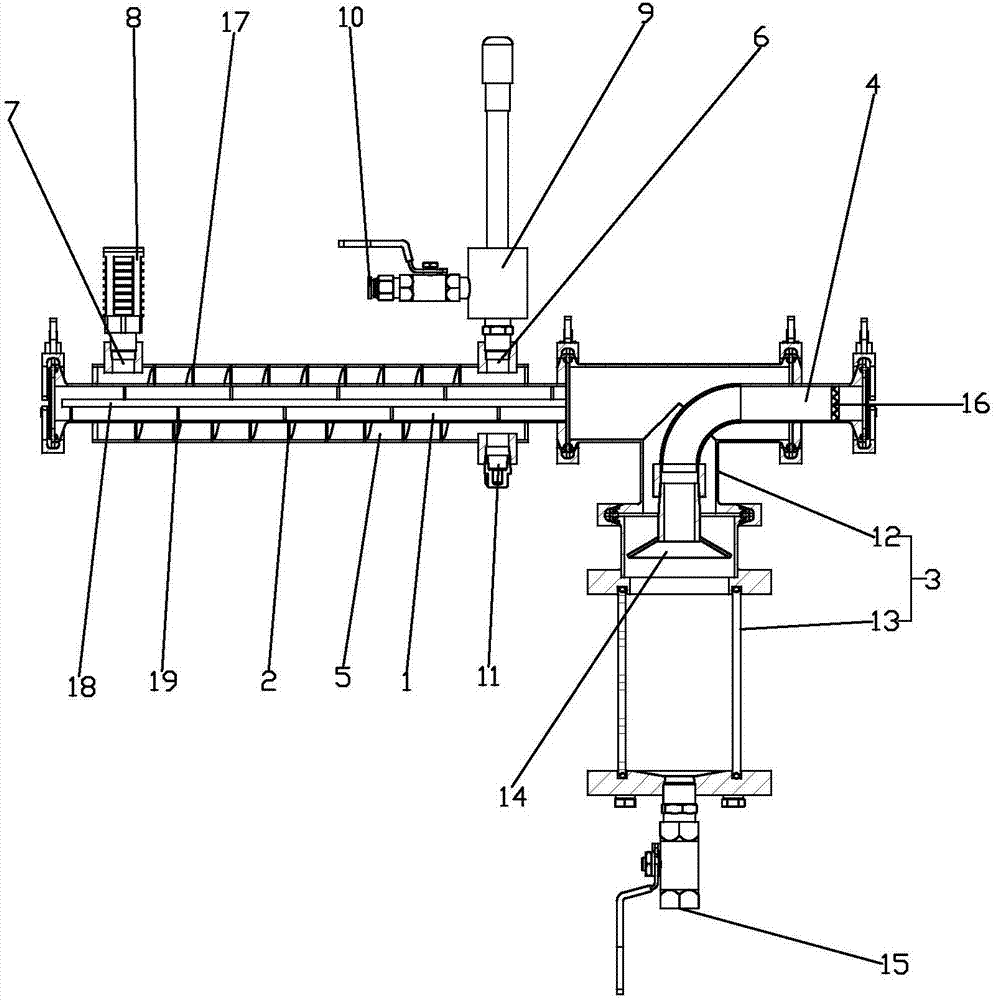

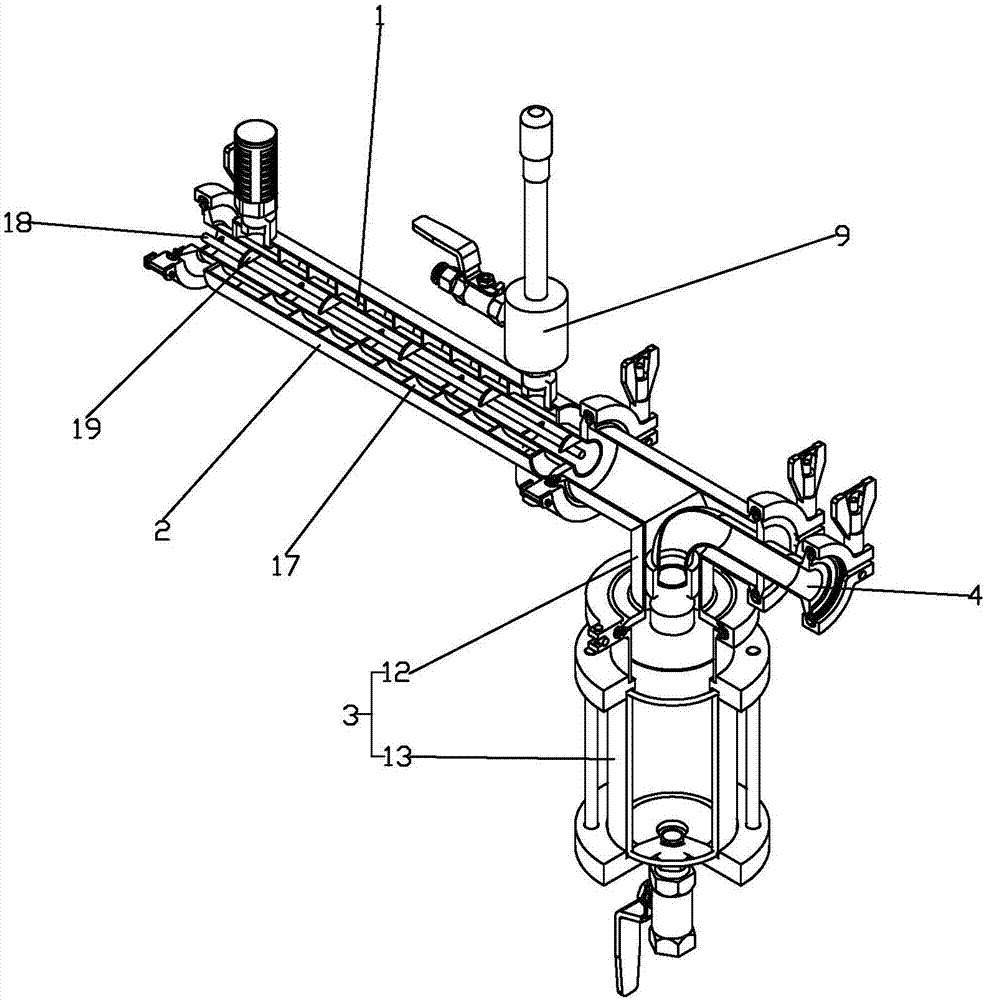

[0017] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

[0018] Such as Figure 1-2 Described a kind of NMP filter comprises waste gas pipe 1, cooling pipe 2, separation pipe 3 and exhaust elbow 4, and one end of waste gas pipe 1 is connected with waste gas discharge equipment, and waste gas discharge equipment discharges the mixed gas containing NMP into waste gas Tube 1. The cooling pipe 2 is sleeved and fixed on the exhaust pipe 1, a cooling channel 5 is formed between the cooling pipe 2 and the exhaust pipe 1, and a cold air inlet 6 and a cold air outlet 7 are respectively provided on the cooling pipe 2 The cold air outlet 7 is provided with a muffler 8, and the cold air in the cooling channel 5 is finally discharged from the cold air outlet 7. The addition of the muffler 8 can reduce the noise generated when the cold air is continuously flowing, thereby providing a quiet working environ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com