Gas distribution and methanation system as well as methanation process system

A process system and methanation technology, applied in the direction of gas fuel, organic chemistry, petroleum industry, etc., can solve the problems of increasing equipment investment, reducing metal wall temperature, and large reaction temperature rise, so as to reduce the difficulty of structural design and reduce the material Requirements, the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

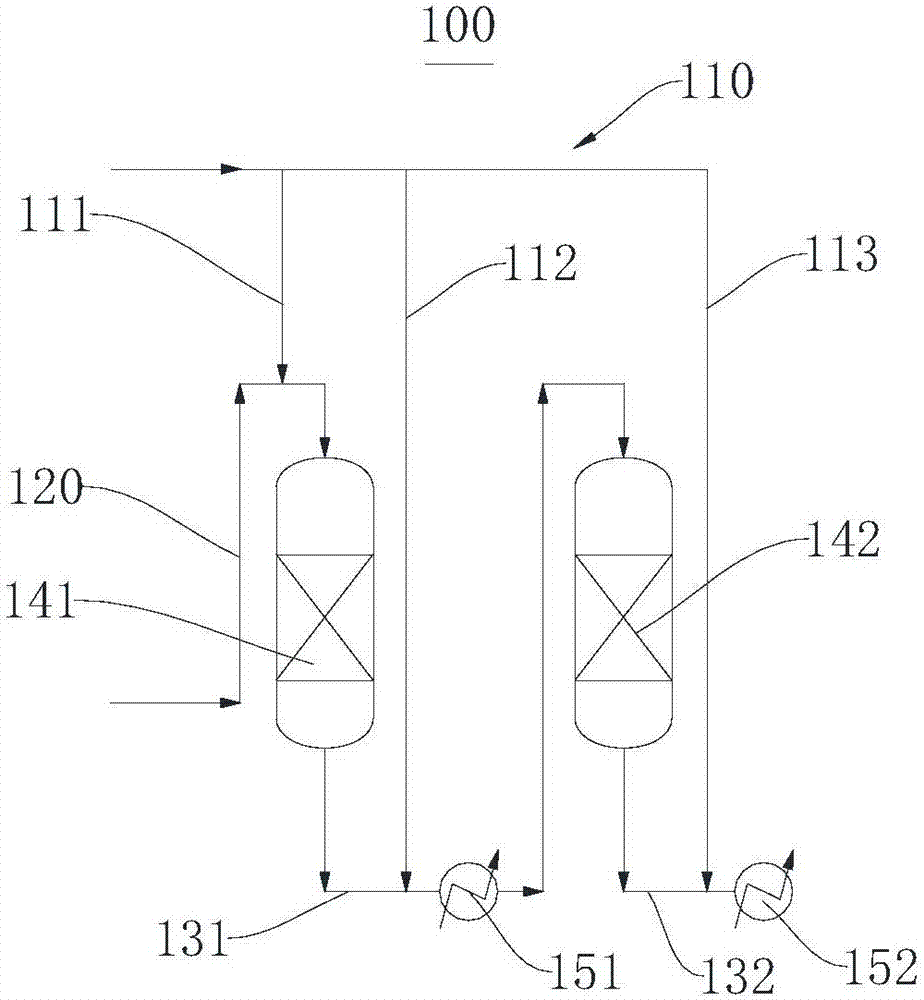

[0034] Please refer to figure 1 This embodiment provides a gas distribution methanation system 100 , including a first gas distribution pipe 110 , a second gas distribution pipe 120 , a first gas transmission pipe 131 , a first reactor 141 and a first waste heat recovery device 151 . The first gas distribution pipe 110 is respectively connected to the first reactor 141 and the first gas delivery pipe 131, the second gas distribution pipe 120 is connected to the first reactor 141, and the first reactor 141 is connected to the first waste heat recovery device through the first gas delivery pipe 131. 151 connections.

[0035] Specifically, the first gas distribution pipe 110 and the second gas distribution pipe 120 are used to input gas into the first reactor 141 and the first waste heat recovery device 151 . A catalyst is placed in the first reactor 141 to catalyze the reaction. A large amount of CO-rich gas can cause catalyst poisoning, but a large amount of H-rich 2 This do...

Embodiment 2

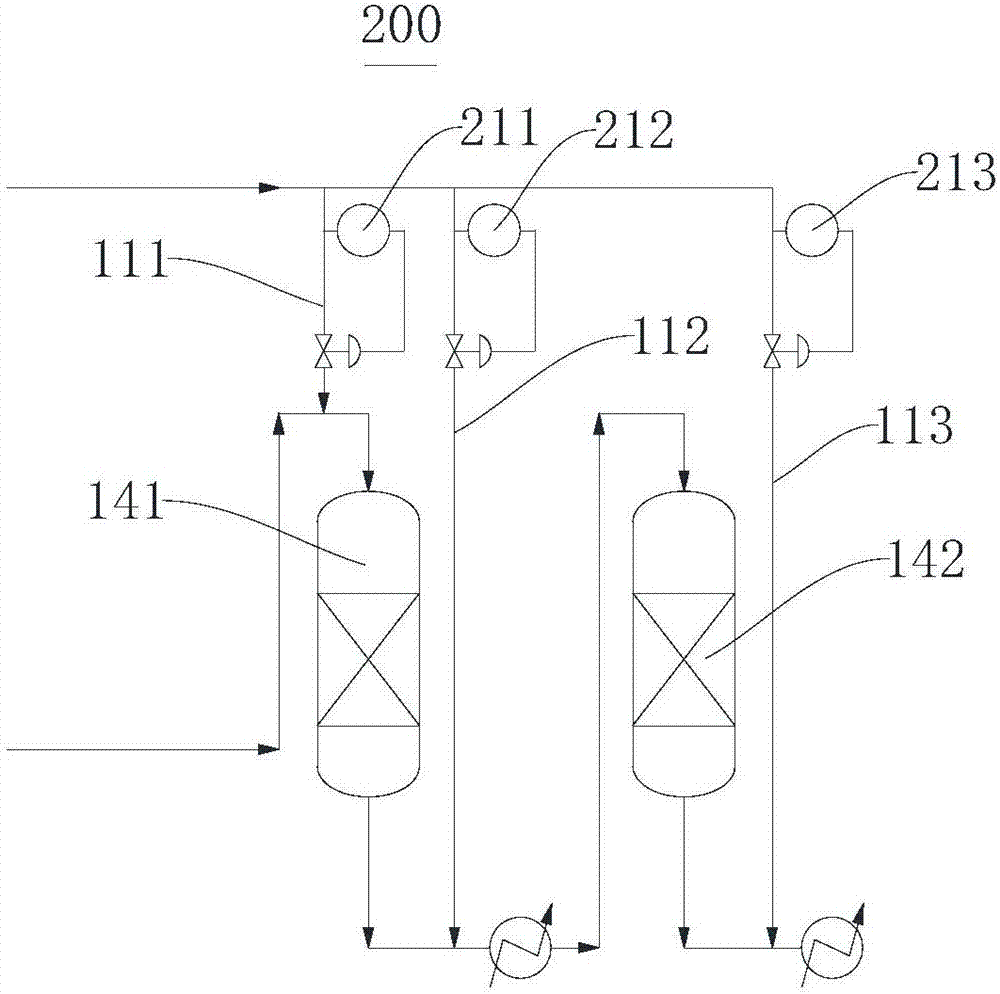

[0041] Please refer to figure 2 , this embodiment provides a gas distribution methanation system 200 .

[0042] The difference between the gas distribution methanation system 200 and the gas distribution methanation system 100 mainly lies in:

[0043] The gas distribution methanation system 200 includes a first flow regulator 211, a second flow regulator 212, and a third flow regulator 213. The first flow regulator 211 is arranged on the first pipeline 111, and is used to adjust the flow rate of the first pipeline 111. The flow rate of the CO-enriched gas, the second flow regulator 212 is arranged in the second pipeline 112 for adjusting the flow rate of the CO-enriched gas transported by the second pipeline 112, and the third flow regulator 213 is arranged in the third pipeline 113 for adjusting The flow rate of the CO-enriched gas delivered by the third pipeline 113. The first flow regulator 211, the second flow regulator 212, and the third flow regulator 213 adjust the C...

Embodiment 3

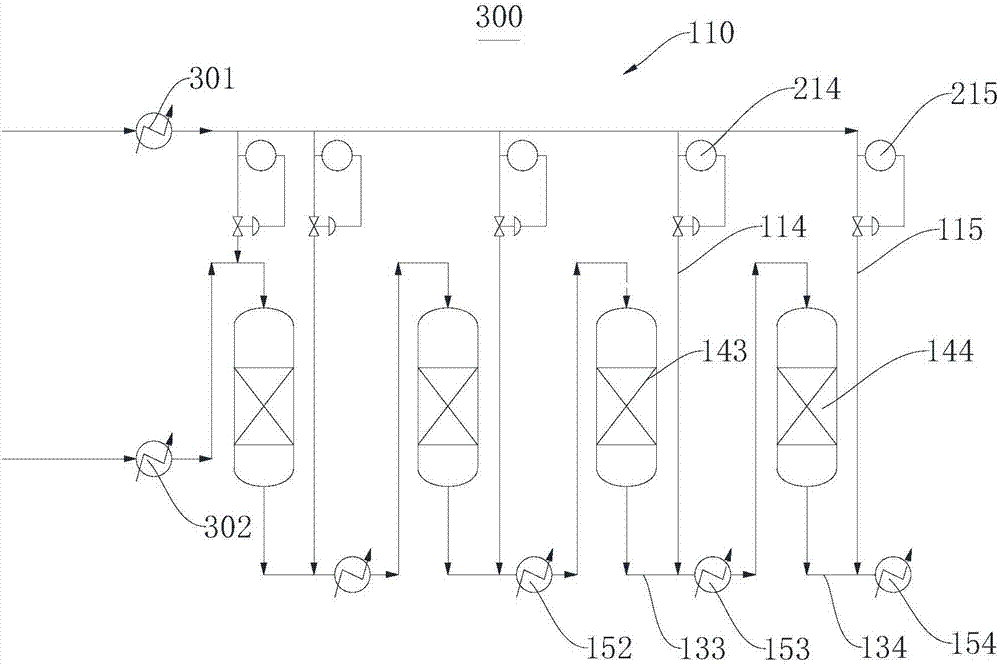

[0047] Please refer to image 3 , this embodiment provides a gas distribution methanation system 300 .

[0048] The difference between gas distribution methanation system 300 and gas distribution methanation system 200 mainly lies in:

[0049] Gas distribution methanation system 300 includes 4 stages of reactions. Specifically, it includes the third reactor 143, the third gas transmission pipe 133, the third waste heat recovery device 153, the fourth reactor 144, the fourth gas transmission pipe 134, and the fourth waste heat recovery device connected in sequence to the second waste heat recovery device 152. 154. The first gas distribution pipe 110 includes a fourth pipeline 114 for delivering CO-rich gas to the third gas delivery pipe 133 and a fifth pipeline 115 for delivering CO-rich gas to the fourth gas delivery pipeline 134. The fourth pipeline 114 and the fifth pipeline 115 are respectively A fourth flow regulator 214 and a fifth flow regulator 215 are provided.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com