Automatic device for machining large roller of textile machine

An automation device and a technology for roller parts, which are applied in the direction of grinding drive devices, grinding workpiece supports, metal processing equipment, etc., can solve the problems of low grinding quality, easy wear of the grinding head on the outer peripheral surface of the roller parts, etc., and achieve grinding efficiency High, simple and reasonable setting, guarantee the effect of grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

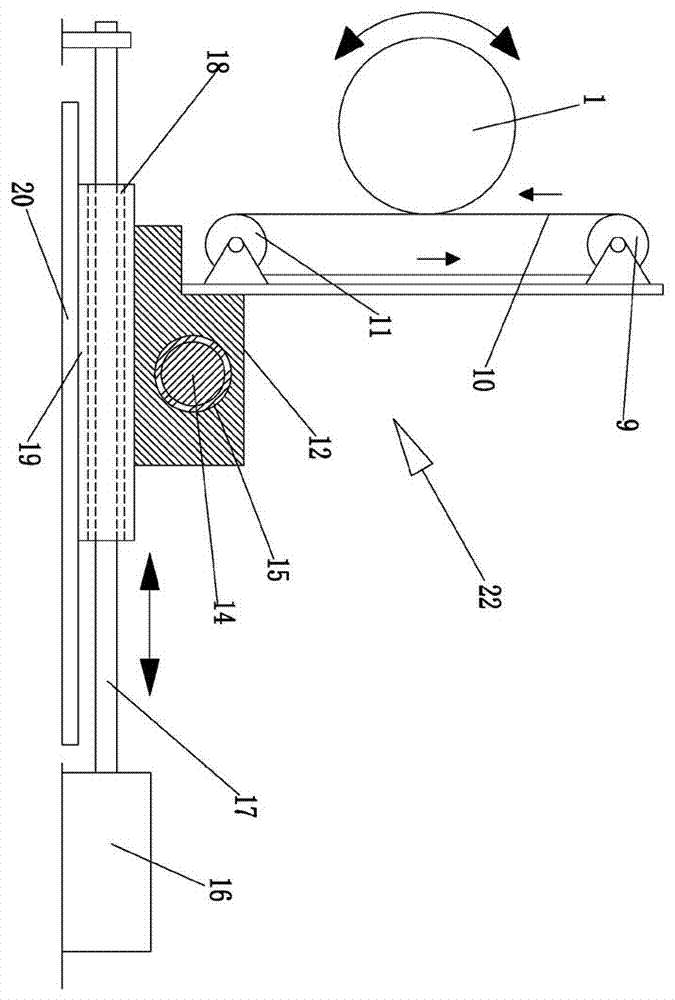

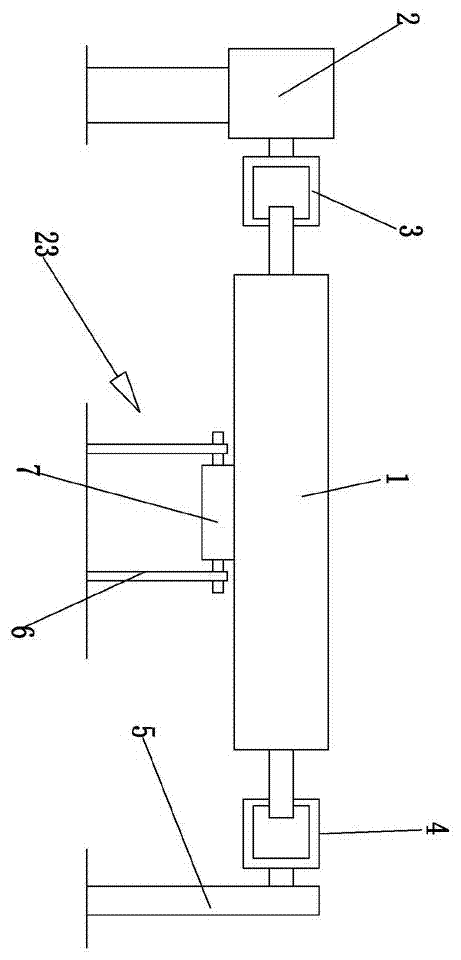

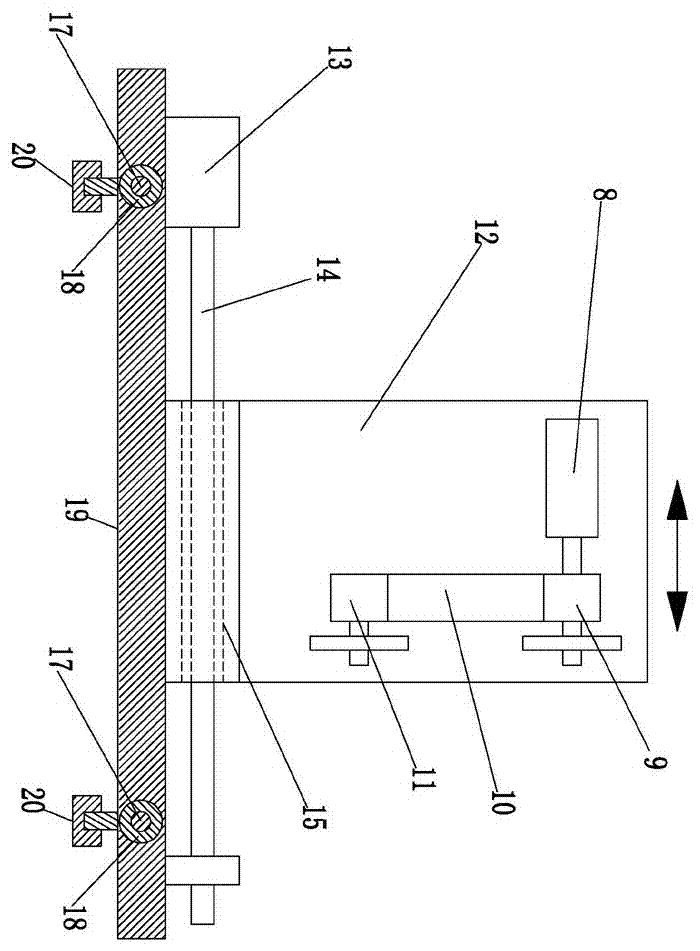

[0017] Such as Figure 1-4 As shown, an automatic device for processing large-scale rolls of textile machinery, including a clamping unit for clamping the roll 1 so that the roll 1 is placed horizontally, and a grinding unit for grinding the outer peripheral surface of the roll 1 22. It also includes a supporting unit 23 for supporting the middle part of the shaft of the roller 1, and also includes a first displacement unit for driving the grinding unit 22 to reciprocate along the axial length of the roller 1, and also includes a first displacement unit for driving the grinding The unit 22 is a second displacement unit that moves horizontally in a direction perpendicular to the central axis of the roller 1 , and also includes a controller 21 .

[0018] Above-mentioned grinding unit 22 comprises the mobile grinding table 12 that is directly controlled by the first displacement unit, also includes grinding action motor 8, driving wheel 9, synchronous wheel 11, the grinding belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com