Hydro-pneumatic suspension hydraulic system

A hydraulic system and oil-pneumatic suspension technology, which is applied in the field of oil-pneumatic suspension hydraulic system and oil-pneumatic suspension, can solve problems such as limiting off-road speed, limiting system performance, and harsh riding environment for occupants, so as to avoid hitting limiters, improve heat dissipation conditions, and improve The effect of vibrating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

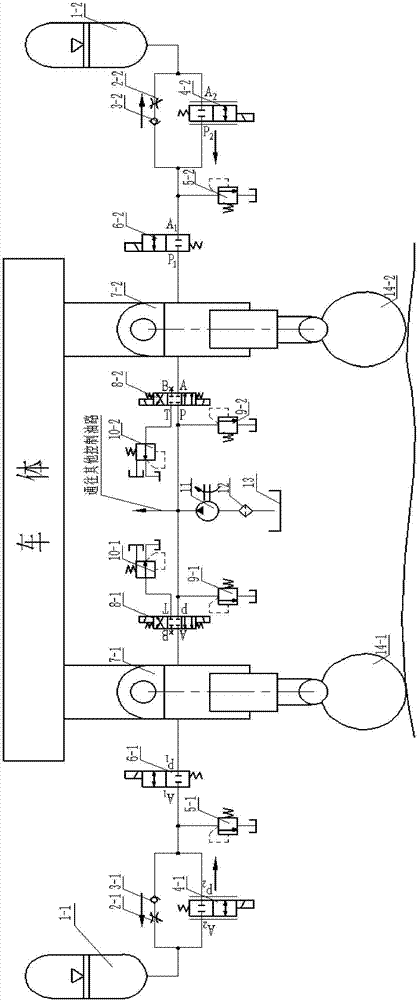

[0022] Such as figure 1 As shown, the present invention discloses an oil-pneumatic suspension hydraulic system, which includes an oil-pneumatic spring and a hydraulic control element. The hydraulic control element includes a first overflow valve, a two-position two-way electromagnetic reversing valve, a three-position four-way electromagnetic reversing valve, a second overflow valve, a back pressure valve, a hydraulic pump 11, a filter 12 and Oil tank 13; among the oil-gas spring and the hydraulic control element, all other components except the suspension cylinder are arranged inside the automobile, and the components are connected through hydraulic oil pipes. In this embodiment, two sets of hydraulic systems are provided, that is, a pair of oil-pneumatic springs and hydraulic control elements are provided, respectively acting on the wheels on both sides of the same axle. The pair of hydraulic control elements share an oil tank 13 , a filter 12 and a hydraulic pump 11 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com