Battery pop-up system of charging station

A charging station and battery technology, applied in charging stations, battery pack components, battery circuit devices, etc., can solve the problems of severe combustion of lithium batteries and difficult fire fighting methods, and achieve simple and reasonable structure, meet fire protection needs, and operate reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

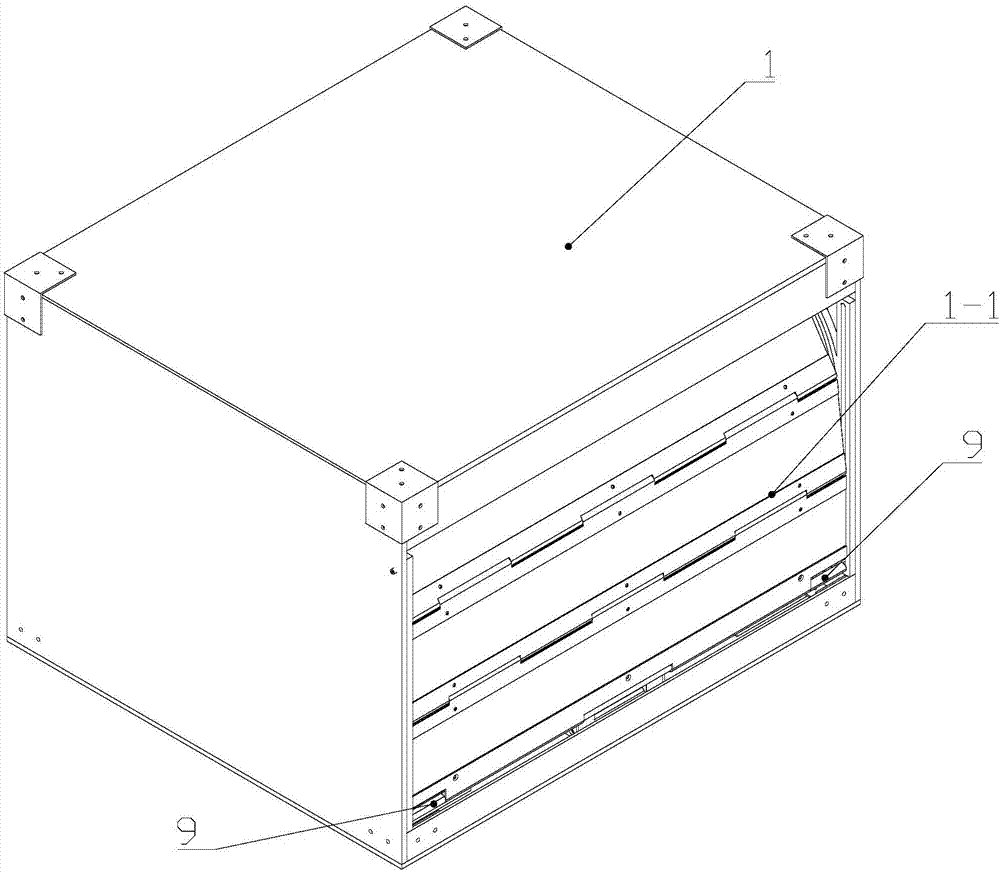

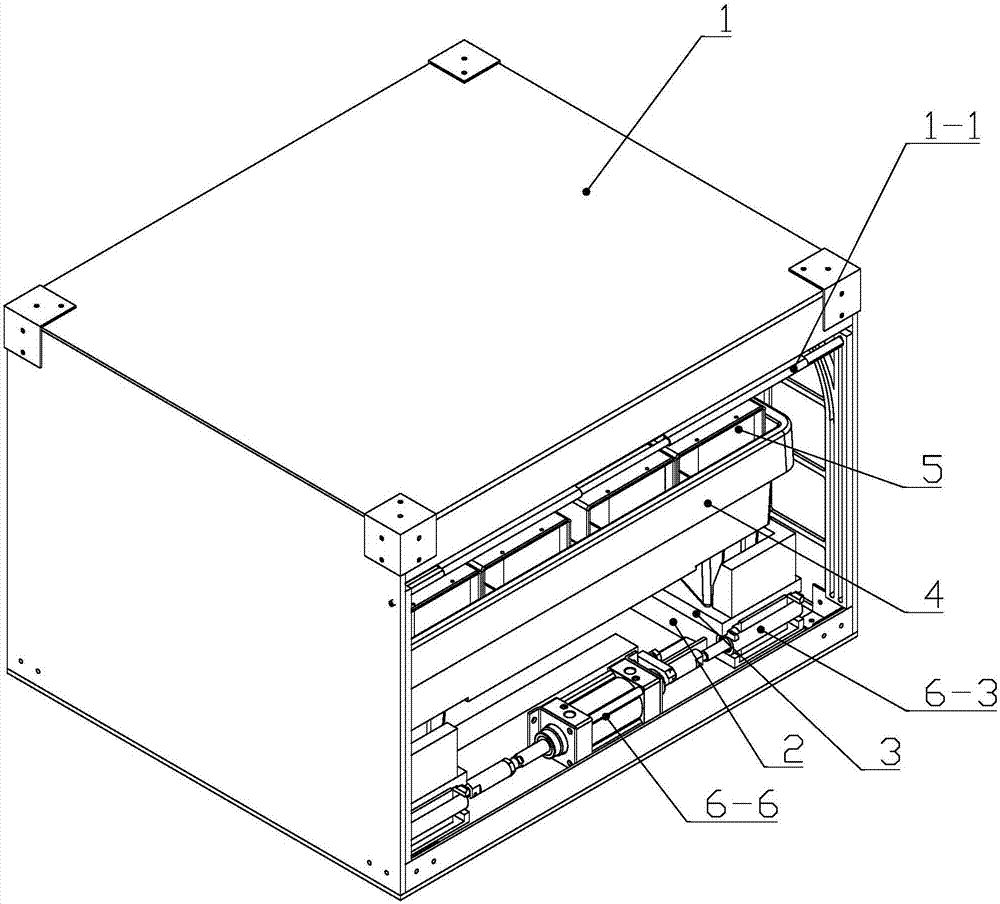

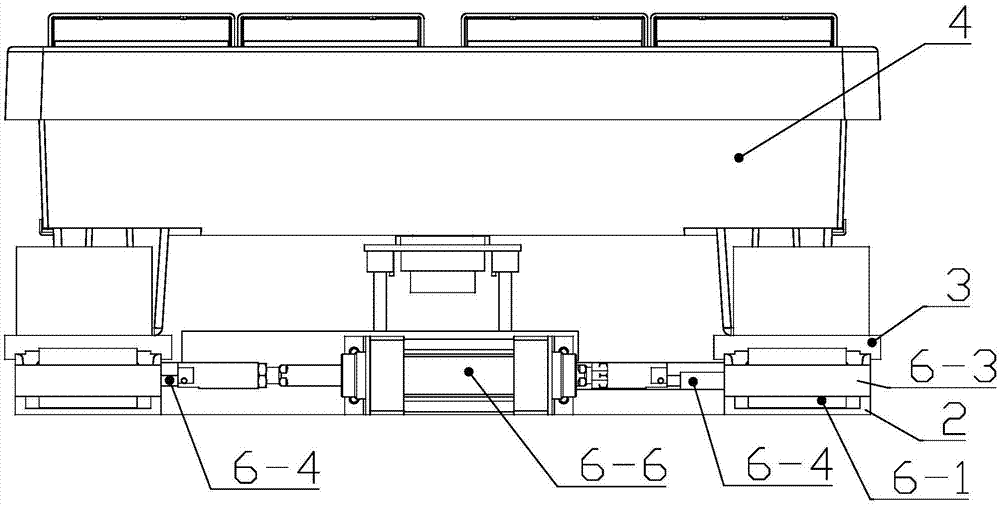

[0031] Example 1, such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10 and 11:

[0032] This embodiment 1 can be applied to the battery directly entering the charging compartment for charging, and can also be applied to the battery being placed in the charging tray and entering the charging compartment for charging. In this embodiment 1, the battery is placed in the charging tray and entered into the charging compartment for charging as an example. Be explained:

[0033] A battery ejection system for a charging station, comprising a battery ejection device, an ejection seat 2, a slide seat 3 and a connector separation device, there are two battery ejection devices, which are respectively located on the left and right sides of the bottom of the charging compartment 1, and are installed on the corresponding In the ejection seat 2 on the side, the connector separation device is arranged between the ejection seats 2 on the left and right sides. The battery 5 is placed in the charging...

Embodiment 2

[0057] Compared with Embodiment 1, the difference is that the sliding seat 3 is omitted, the charging tray 4 is directly seated on the ejection seat 2, and is guided by the ejection seat 2 like the sliding seat 3, and the ejection block 6-1 directly acts on the charging on tray 4.

Embodiment 3

[0059] Compared with Embodiment 2, the ejection seat 2 is further omitted, and the ejection block 6-1 and the charging tray 4 are guided to slide forward and backward in a straight line through respective guide structures such as slide rails and guide posts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com