High-density crushing briquetting machine

A briquetting machine, high-density technology, applied in packaging, packaging item types, special packaging items, etc., can solve the problems of restricting the development of deep processing industry, easy to fly around, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

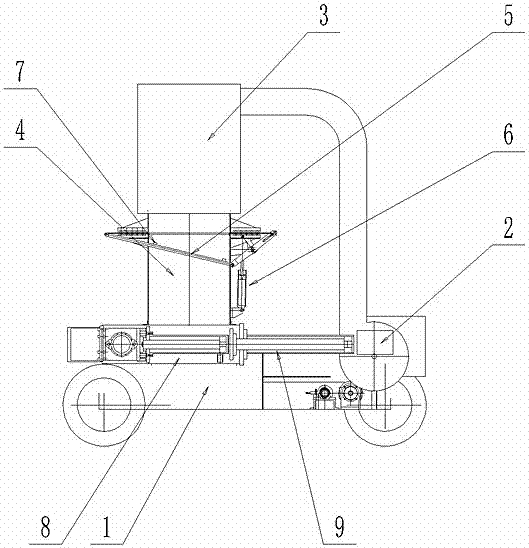

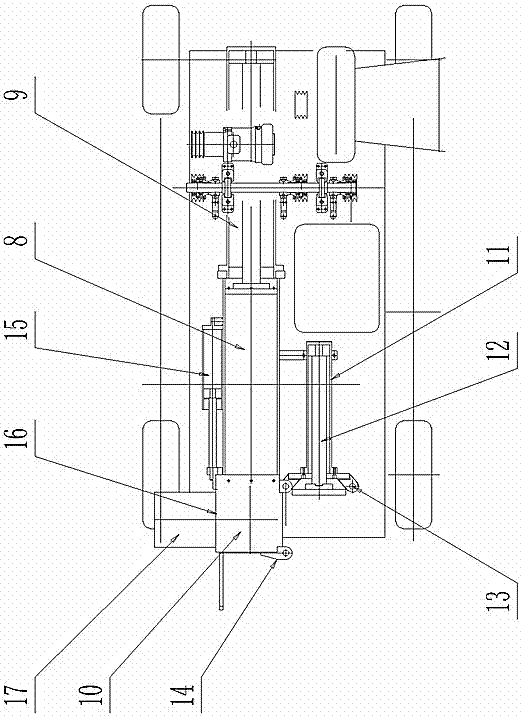

[0009] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 , figure 2 Shown: a high-density crushing and briquetting machine, including a car body 1 as a base, on which a material inlet 2 is arranged, and this material inlet 2 is connected with a collection box 3 through a pipeline. An air pump is arranged in the collecting box 3, and a material channel 4 is connected to the bottom of the collecting box 3, and a flap 5 is hinged in the middle of the material channel 4, and the flap 5 passes through the turning cylinder hinged on the shell of the material channel 4 6 for driving, and a quality sensor 7 is provided on the turnover plate 5, and the bottom end of the material channel 4 is also connected with the axial pressing chamber 8 provided on the vehicle body 1, and an axial pressure chamber 8 is provided on the vehicle body 1. Pressing material cylinder 9, and the pressing head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com