Tempered antibacterial glass and preparation method and application thereof

An antibacterial glass and tempering technology, applied in the field of glass manufacturing, can solve the problems of weakened sensitivity, glass quality degradation, indirect contact, etc., achieve good surface stress and bending strength, long-term antibacterial activity, and overcome blockage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

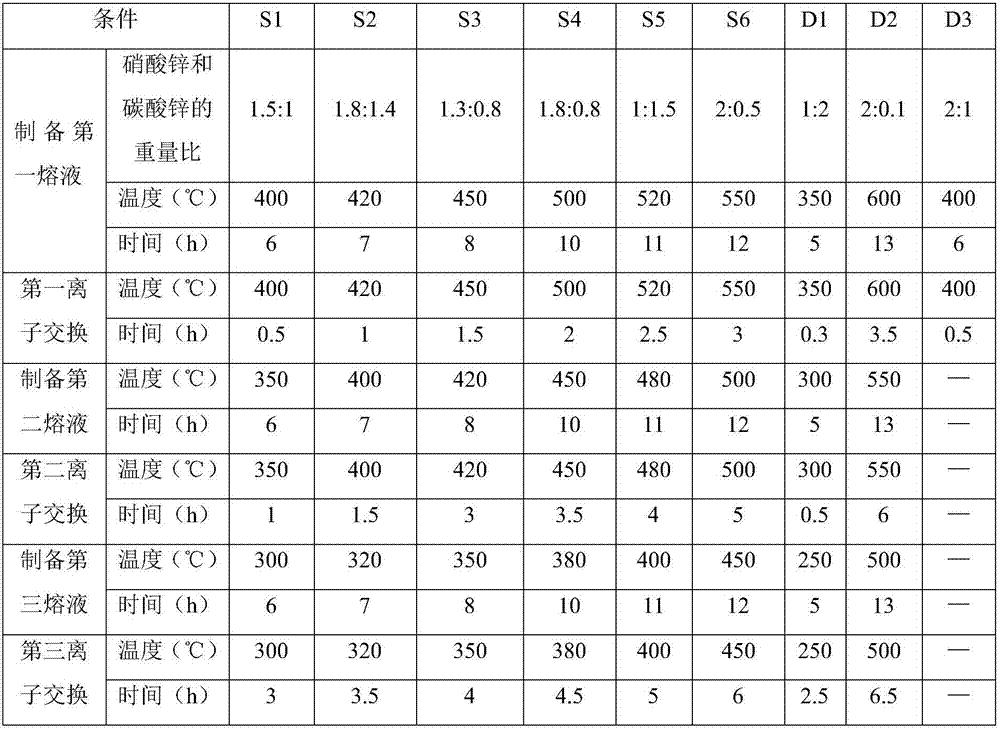

[0022] The first aspect of the present invention provides a kind of preparation method of tempered antibacterial glass, wherein, the method comprises the following steps:

[0023] (1) heating zinc nitrate and zinc carbonate to melt to obtain a first melt, in which the plain glass is subjected to first ion exchange to obtain a first cover glass;

[0024] (2) heating silver nitrate to melt to obtain a second melt, in which the first cover glass obtained in step (1) is subjected to a second ion exchange to obtain a second cover glass;

[0025] (3) Heating potassium nitrate to melt to obtain a third melt, in which the second cover glass obtained in step (2) is subjected to third ion exchange to obtain tempered antibacterial glass.

[0026] In the present invention, the plain glass is untempered glass.

[0027] In the present invention, in step (1), the weight ratio of zinc nitrate to zinc carbonate is (1-2):(0.5-1.5), preferably (1.3-1.8):(0.8-1.4). Zn in the zinc nitrate and zi...

Embodiment 1

[0047] (1) The first ion exchange

[0048] Heat 100 g of zinc nitrate and zinc carbonate at a weight ratio of 1.5:1 at 400° C. for 6 h to melt to obtain the first melt. In the first melt, the cover glass is subjected to the first ion exchange, the temperature of the first ion exchange is 400° C., and the time is 30 min, to obtain the first cover glass.

[0049] (2) Second ion exchange

[0050] Heat 100g of silver nitrate at 350°C for 6h to melt to obtain the second melt. In the second melt, the first cover glass obtained in step (1) is subjected to the second ion exchange, the temperature of the second ion exchange is 350° C., and the time of ion exchange is 1 h to obtain the second cover glass .

[0051] (3) The third ion exchange

[0052] Heat 100g of potassium nitrate at 300°C for 6h to melt to obtain the third melt. In the third melt, the second cover glass obtained in step (2) was subjected to the third ion exchange, the temperature of the third ion exchange was 300°...

Embodiment 2-6

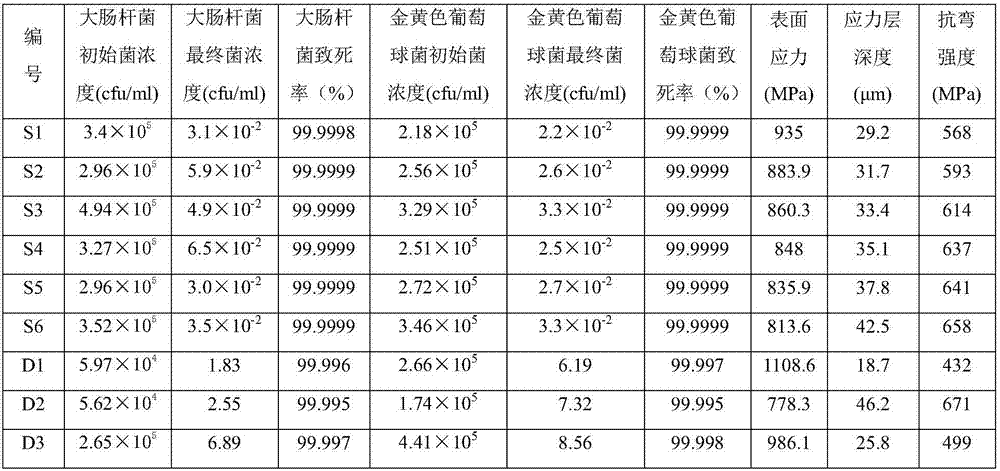

[0057] According to the method of Example 1, the difference is that tempered antibacterial glasses S2-S6 were prepared according to the conditions in Table 1.

[0058] According to the method of Example 1, the performance test was carried out, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface stress | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com