Safe, efficient and energy-saving technological process for extracting artemisinin or artemisia annua extract

A high-efficiency, energy-saving, technological process technology, applied in the direction of organic chemistry, can solve the problem of low safety factor, achieve the effect of reducing steam and power consumption, saving solvent, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

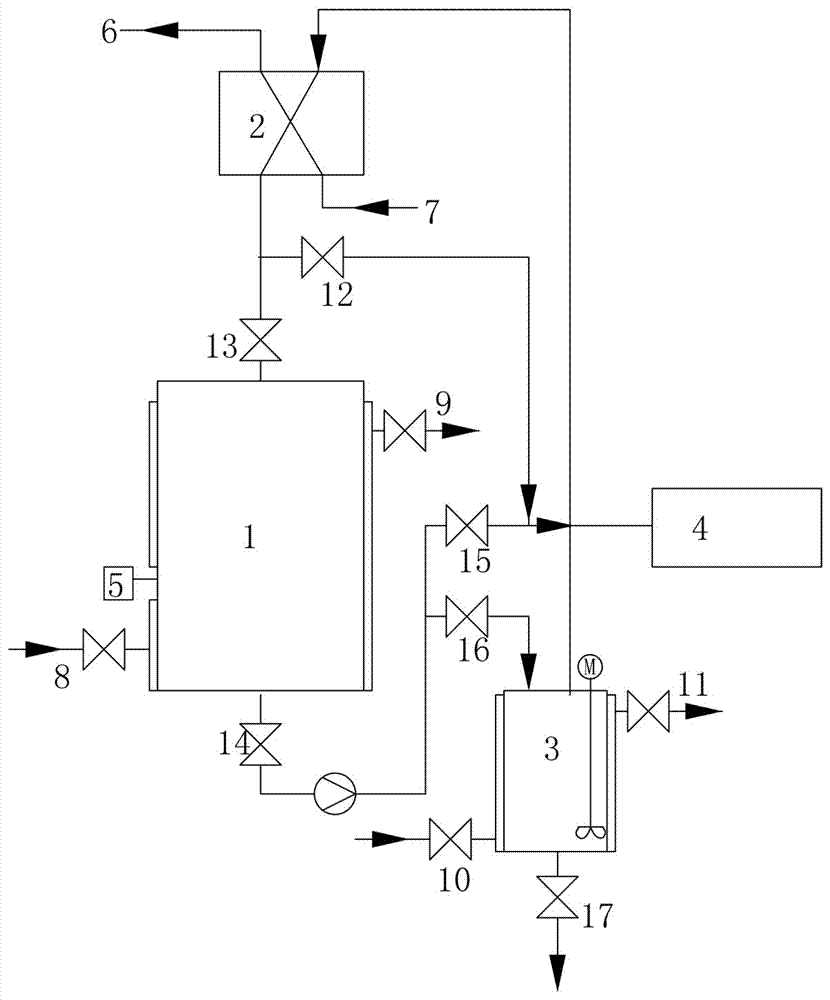

[0028] A safe, high-efficiency and energy-saving technological process for extracting artemisinin paste or artemisinin, comprising the following steps:

[0029] A. Add Artemisia annua leaves from the feed valve 13 of the percolation tank to the percolation tank 1, then add dichloromethane to completely submerge the leaves of Artemisia annua in the percolation tank, and then open the heating valve 8 of the percolation tank to heat the temperature. When the temperature reaches 35-40°C, turn on the ultrasound source 5 for ultrasound;

[0030] B. After half an hour of ultrasonication, open the discharge valve 14 of the percolation tank and the feed valve 16 of the concentration tank, so that the percolation liquid in the percolation tank 1 enters the concentration tank 3. When the percolation liquid in the concentration tank 3 reaches When 80% of its volume, open the enrichment tank heating valve 10 and start to concentrate;

[0031] C, open the cooling circulating water while op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com