Gear transmission structure with mute and low abrasion

A technology of gear transmission and low wear, which is applied in the direction of gear transmission, gear vibration/noise attenuation, transmission, etc. It can solve the problems of difficult noise elimination, lubricating oil separation, and inability to reduce friction, so as to reduce wear and occupancy space, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

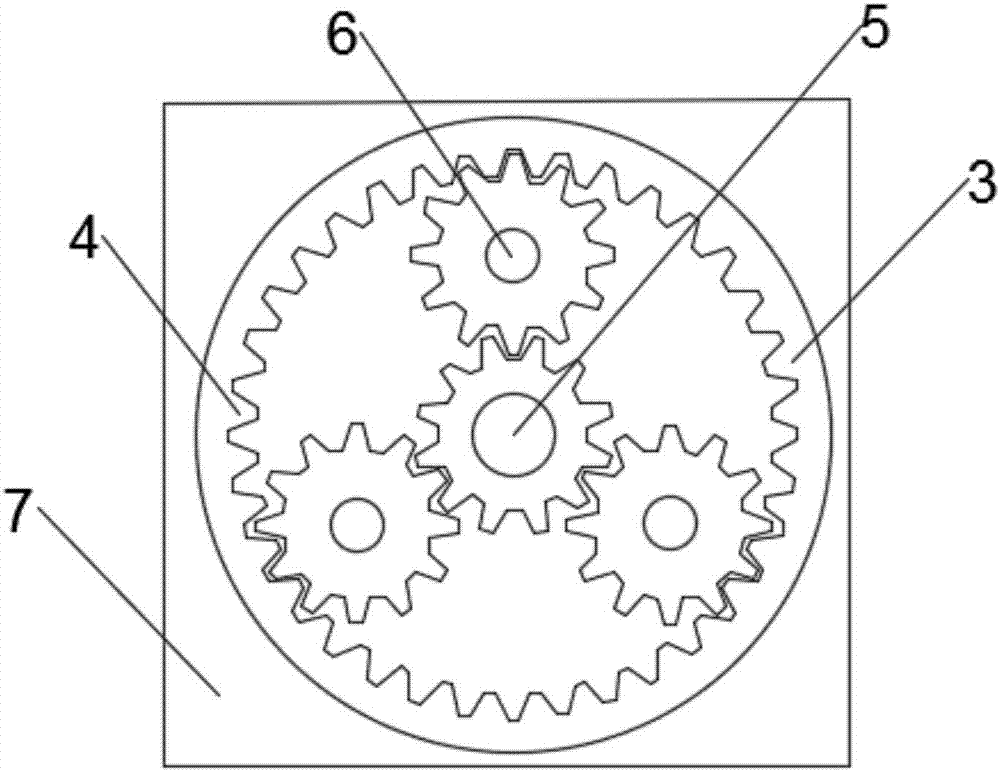

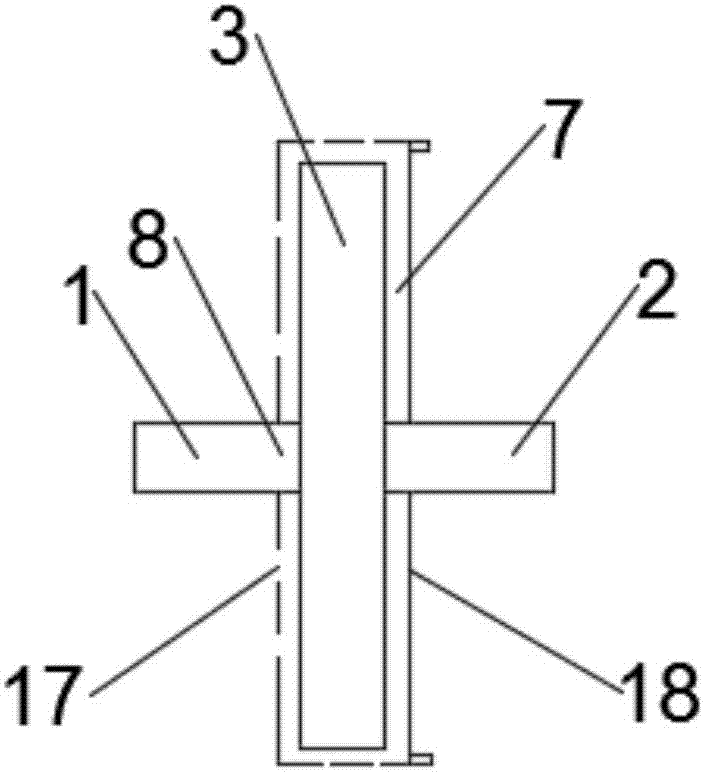

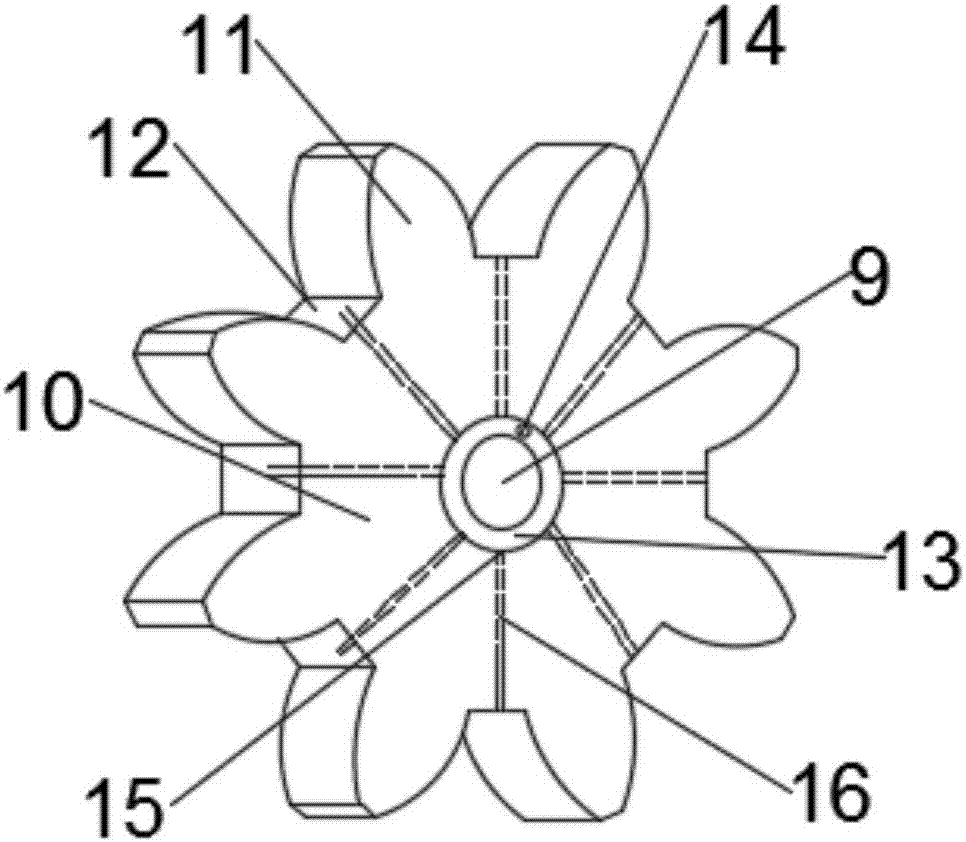

[0021] Such as Figure 1 to Figure 3 As shown, the present invention provides a quiet and low-wear gear transmission structure, including an output shaft 1 and an input shaft 2, the output shaft 1 is connected with a ring gear 3, and the ring gear 3 is an annular structure, and the gear The inner wall of the ring 3 is provided with a number of output gear teeth 4 evenly distributed, the input shaft 2 is connected with an input gear 5, and the input gear 5 meshes with three identical planetary gears 6 respectively, and the three planetary gears 6 are simultaneously connected with the The ring gear 3 is meshed, and the outside of the ring gear 3 is covered with a soundproof box 7, and the two sides of the soundproof box 7 are respectively provided with through holes 8, and the input shaft 2 and the output shaft 1 protrude from the through holes 8, respectively. Both the input gear 5 and the planetary gear 6 include a hub 9, a wheel disc 10, gear teeth 11 and a wheel groove 12, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com