Steel strip reinforced polyethylene helically-corrugated drain pipe foundation structure and construction method thereof

A polyethylene spiral and foundation structure technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of radially displaced pipelines, excessive backfill height, and loose foundation, etc., and achieve improvement Efficiency, low flow resistance, and smooth inner wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

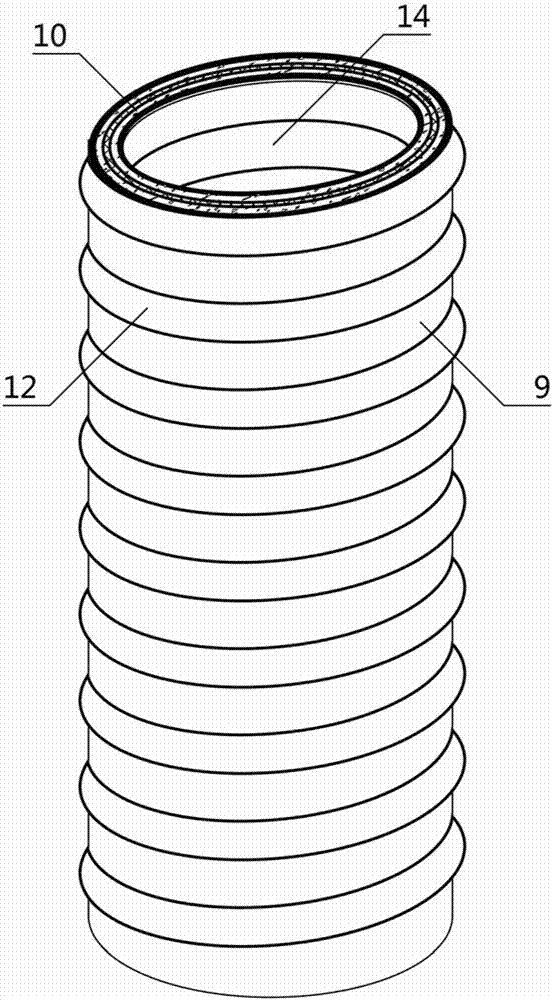

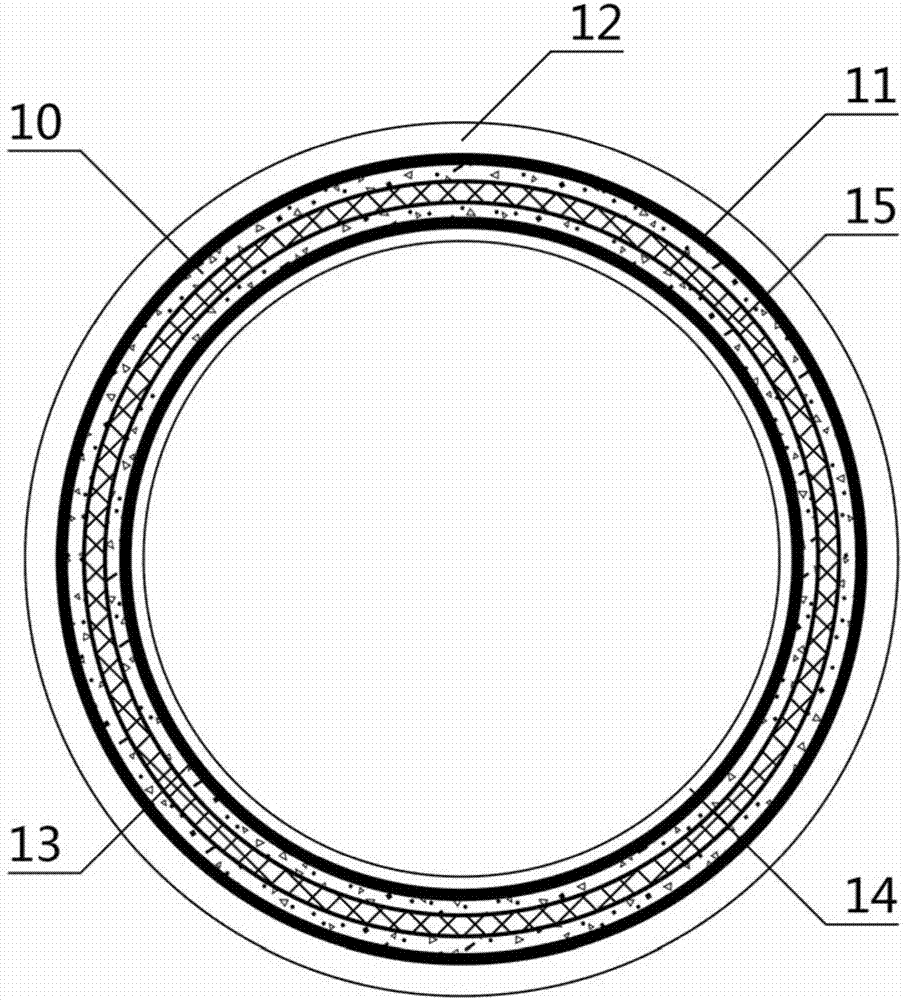

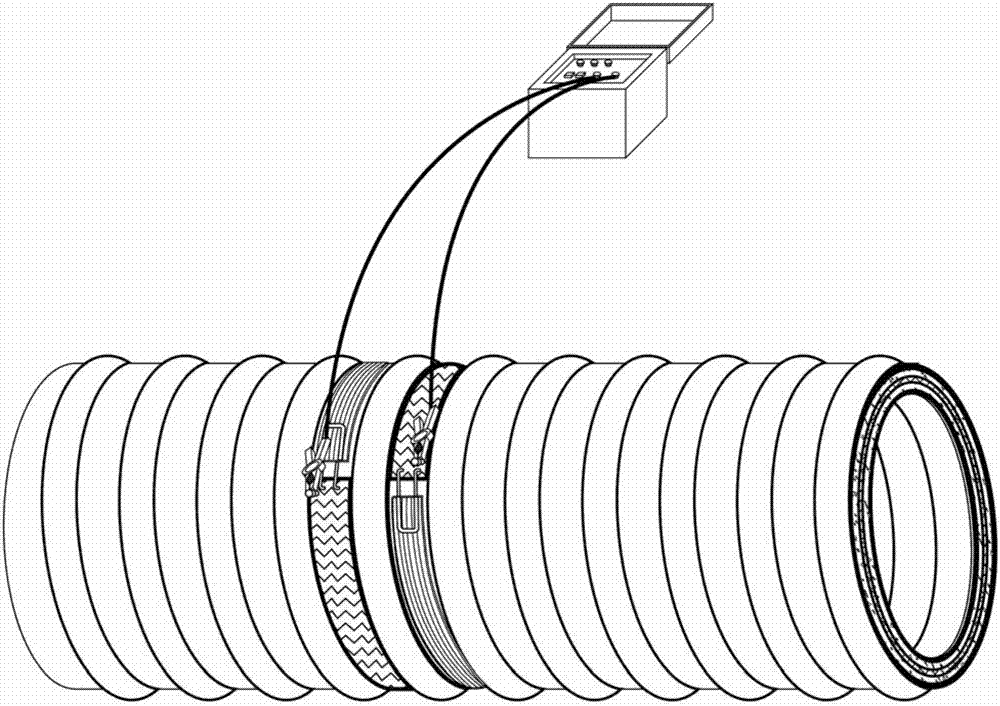

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7Shown is a steel belt reinforced polyethylene spiral corrugated drainage pipe foundation structure and its construction method, which is characterized in that: a trench 1, an anti-seepage geomembrane 3, a laying layer 4, pouring water 7, a vibrating rod 8 and a drainage pipe 9 components, the trench 1 is also provided with several drains 2, any of the drains 2 is located in the lower part of the trench 1, the drains 2 and the trench 1 are fixedly connected, and the anti-seepage geomembrane 3 is located inside the trench 1, the anti-seepage geomembrane 3 is fixedly connected to the trench 1, the paving layer 4 is located on the top of the anti-seepage geomembrane 3, and the paving layer 4 and the anti-seepage geomembrane 3 are fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com