Long-afterglow retroreflector with excitation light sources

A retro-reflector and excitation light source technology, which is applied in the direction of illuminated marks, optics, instruments, etc., can solve the problems of failing to meet national standards and industry requirements, weakening of reflective performance, and limitation of reflective brightness and light-emitting angle and distance, and achieve improvement. Reflective performance and afterglow luminous performance, avoiding the effect of single afterglow luminous color and reducing light energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

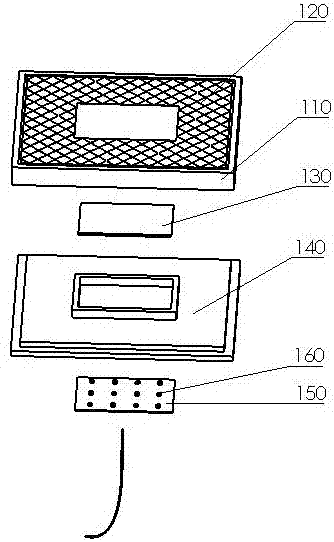

[0099] A square long afterglow retro-reflector with an excitation light source, such as figure 2 As shown, it includes a light-transmitting layer (110), a prism type retroreflective unit array layer (120), a long-lasting luminescent material (130), a bottom plate layer (140), a reflective layer (150), and an excitation light source (160).

[0100] Light-transmitting layer (110):

[0101] The light-transmitting layer (110) is a square transparent shell made of transparent PMMA resin through an injection molding process.

[0102] Prism type retroreflective element array layer (120):

[0103] The prism-type retro-reflective unit array layer (120) is a prism-type retro-reflective unit array layer formed integrally with the transparent layer (110) through the injection molding process of transparent PMMA resin, and is distributed around the bottom surface of the transparent layer (110) in a zigzag shape.

[0104] The lower part of the prism-type retroreflective unit array layer ...

Embodiment 2

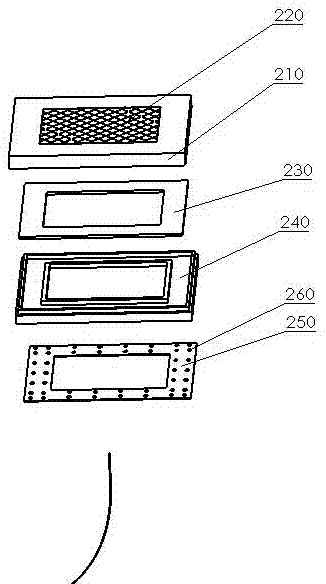

[0115] A square long afterglow retro-reflector with an excitation light source, such as image 3 As shown, it includes a light-transmitting layer (210), a prism-type retroreflective unit array layer (220), a long-lasting luminescent material (230), a bottom plate layer (240), a reflective layer (250), and an excitation light source (260).

[0116] Light-transmitting layer (210):

[0117] The light-transmitting layer (210) is a square transparent shell made of transparent PC resin through an injection molding process, and the middle area of the bottom surface of the light-transmitting layer (210) is pasted with a micro-prism reflective film with transparent glue.

[0118] Prism type retroreflective element array layer (220):

[0119] The prism-type retro-reflective unit array layer (220) is a rectangular micro-prism reflective film, which is pasted on the middle area of the bottom surface of the light-transmitting layer (210) with transparent glue.

[0120] Long Persisten...

Embodiment 3

[0127] A trapezoidal long-persistence retro-reflector with an excitation light source, such as Figure 4 As shown, it includes a light-transmitting layer (310), a prism-type retroreflective unit array layer (320), a long-lasting luminescent material (330), a bottom plate layer (340), a reflective layer (350), and an excitation light source (360).

[0128] Light-transmitting layer (310):

[0129] The light-transmitting layer (310) is a trapezoidal light-transmitting layer made of transparent PMMA resin through an injection molding process. Light-transmitting holes are arranged in an array on the light-transmitting layer (310); convex ribs are arranged on the bottom surface of the light-transmitting layer (310).

[0130] Prism type retroreflective element array layer (320):

[0131] The prism-type retroreflection unit array layer (320) is a microprism reflective plate formed integrally with the transparent PMMA resin and the light-transmitting layer (310) through an injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com