Mobile vision inspecting equipment and method for detection of electric instruments

An electrical instrument and mobile technology, applied in the field of mobile visual inspection equipment, can solve the problems of high cost, long monitoring cycle, and affecting monitoring work, and achieve the effect of strong versatility in occasions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

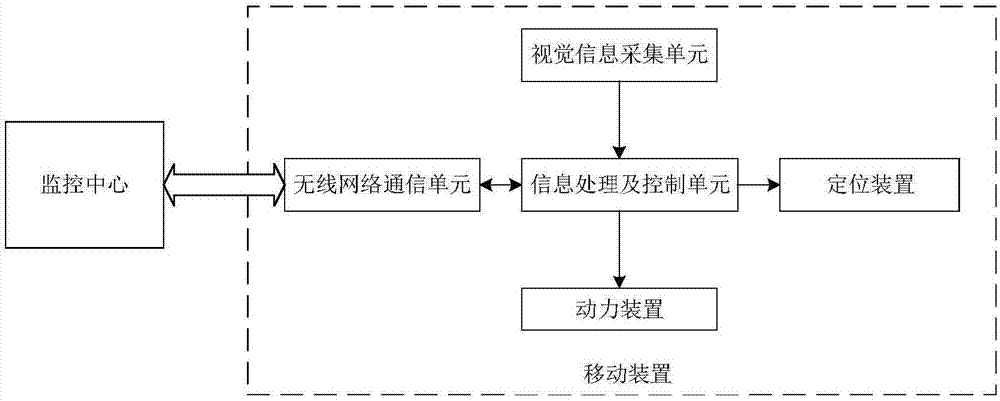

[0034] like figure 1 As shown, the mobile visual inspection equipment for electrical instrument detection of the present invention includes a mobile device and a monitoring center.

[0035] The monitoring center takes the server as the platform, and the software of the monitoring center realizes the functions of database management and human-computer interaction interface.

[0036] Mobile device, including information processing and control unit, positioning device, wireless network communication unit, power device, visual information acquisition unit,

[0037] The output end of the visual information acquisition unit is connected to the input end of the information processing and control unit, the positioning device and the power device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com