Ionic exchange membrane cell management and background data processing system

A technology of ionic membrane electrolyzer and background data, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of lower production efficiency, heavy workload, complicated equipment, etc., and achieve the effect of reducing investment, reducing pressure and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

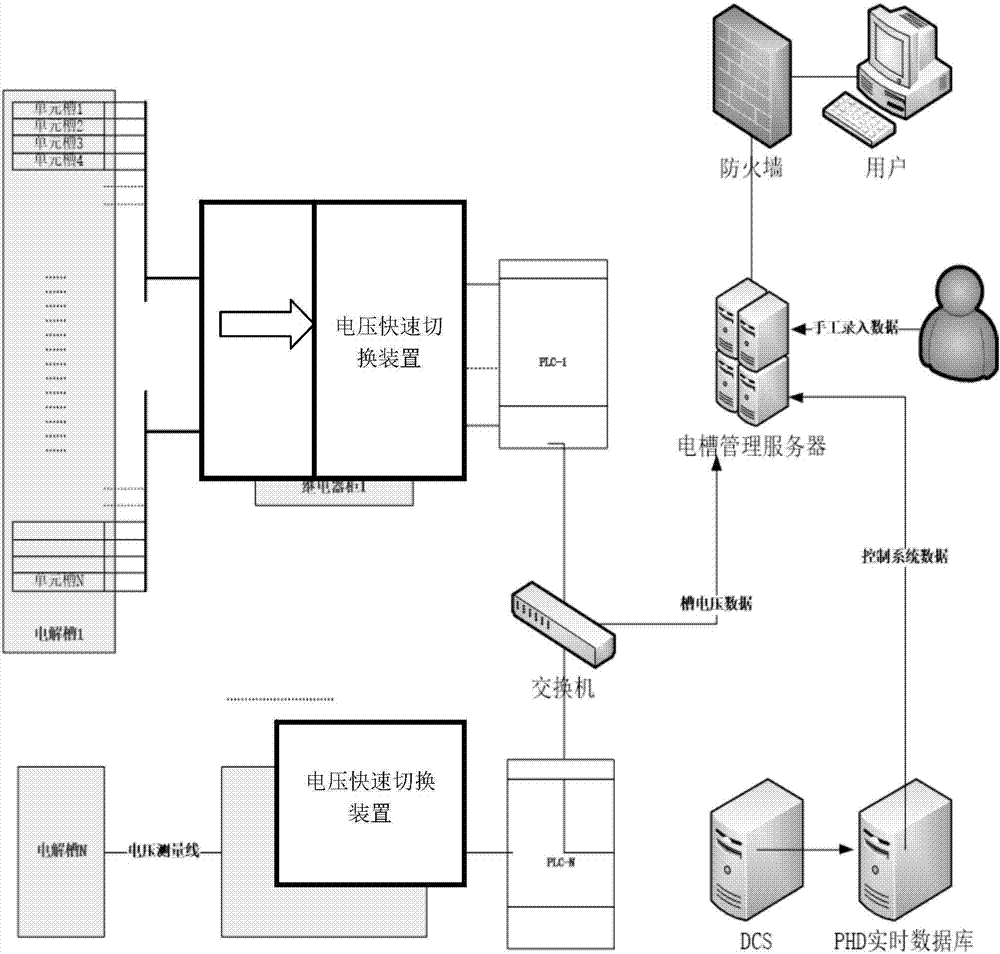

[0023] An ionic membrane electrolyzer management and background data processing system, including electrolyzer groups, connecting wires, voltage fast switching devices, PLC, switch electrolyzer service manager, user terminal, DCS, PHD real-time database;

[0024] There are N groups of electrolytic cell groups, and each group of electrolytic cell groups includes n unit electrolytic cells, and each unit cell is connected to the voltage fast switching device through a separate connection line, and connected to the PLC through a data line. In the present invention, due to the large number of voltage measurement points in the unit tank, often thousands, and the limitation of the number of PLC signal inputs, the method of directly connecting the measurement signal of each unit tank to the PLC cannot be realized. The present invention creatively contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com