Visible evaluation device and method for shale gas well multi-stage fracturing cement sheath air-tight seal integrity

A technology for shale gas wells and evaluation devices, which is applied in construction and other fields, can solve problems such as inability to visualize description and evaluation, optimization design of cement sheath mechanical parameters, and inability to better guide fracturing construction parameters, etc., to achieve simple structure and high work efficiency High, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0038] The application principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

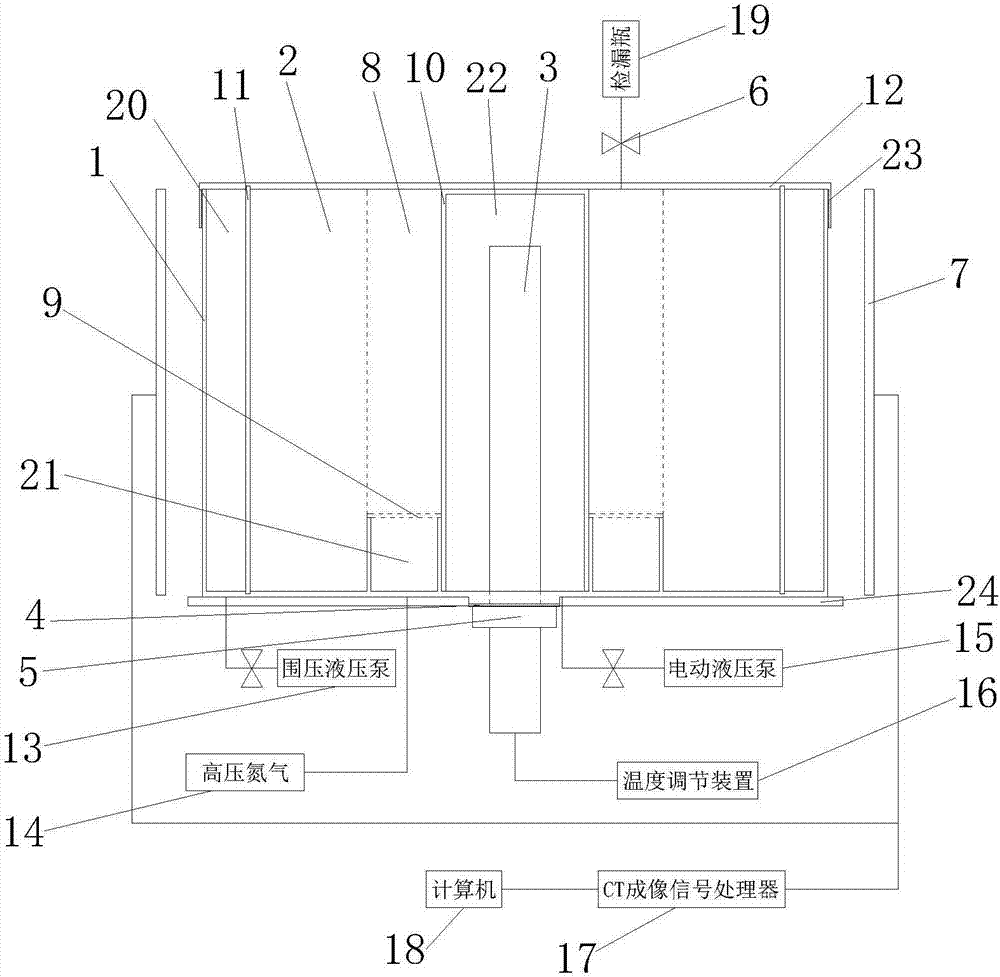

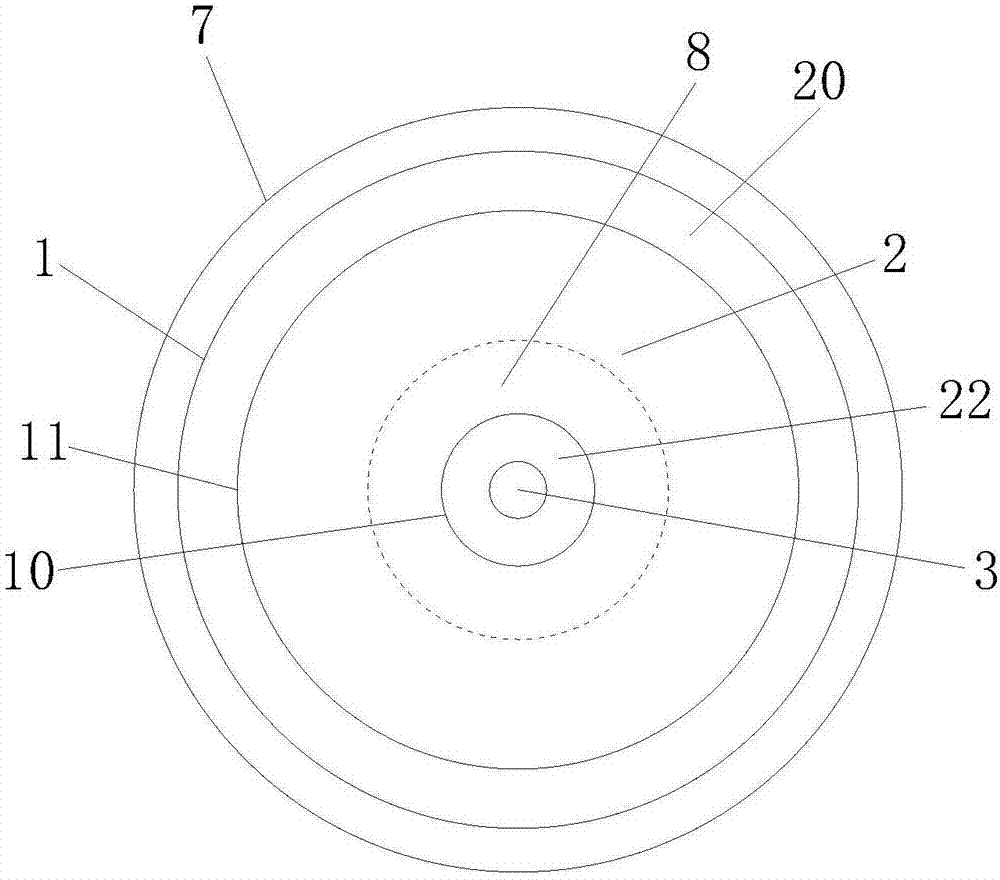

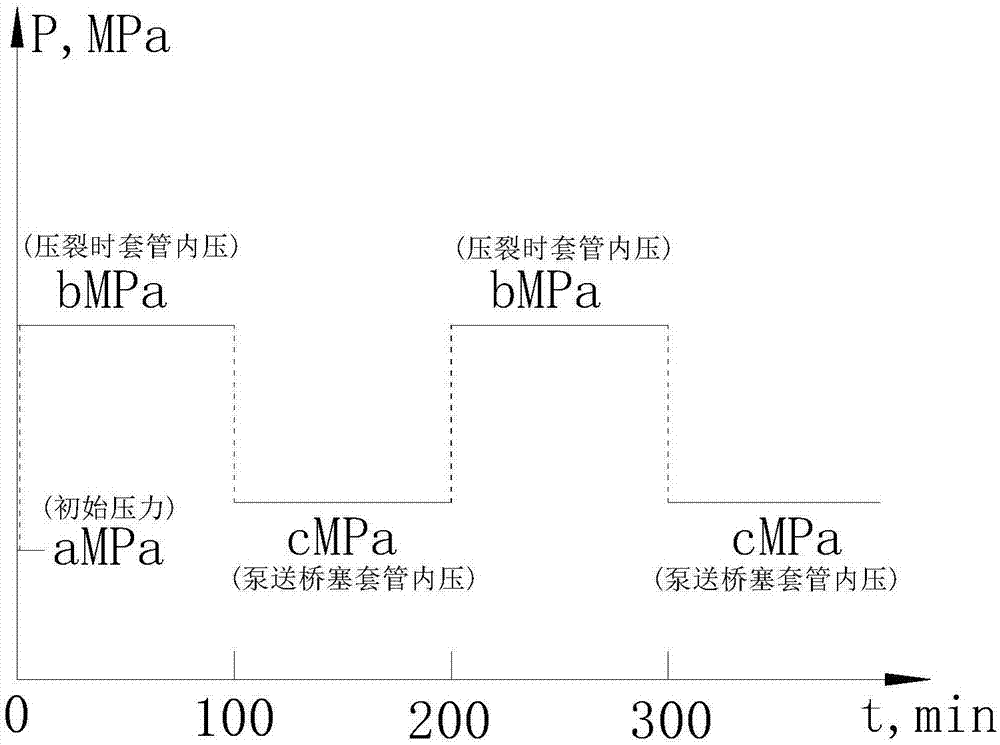

[0039] Such as Figure 1 ~ Figure 4As shown, the shale gas well multi-stage fracturing cement sheath integrity visual evaluation device and method provided by the embodiment of the present invention has a structure comprising: a test bench 24, a kettle body 1, which is a model of the entire device, and a kettle body 1 There is a cylindrical shape at the bottom of the middle, with screw holes on it, forming multiple rings outward from the center of the circle. From the center of the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com