Environmental medium pressure adaptive sealing-packing pressing device

An environmental medium and sealing packing technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of difficulty in ensuring the normal use of the drive shaft, inability to prevent outboard seawater, and difficulty in quickly pressing the packing, etc., to ensure the sealing performance, low energy consumption requirements, the effect of reducing the burden on personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

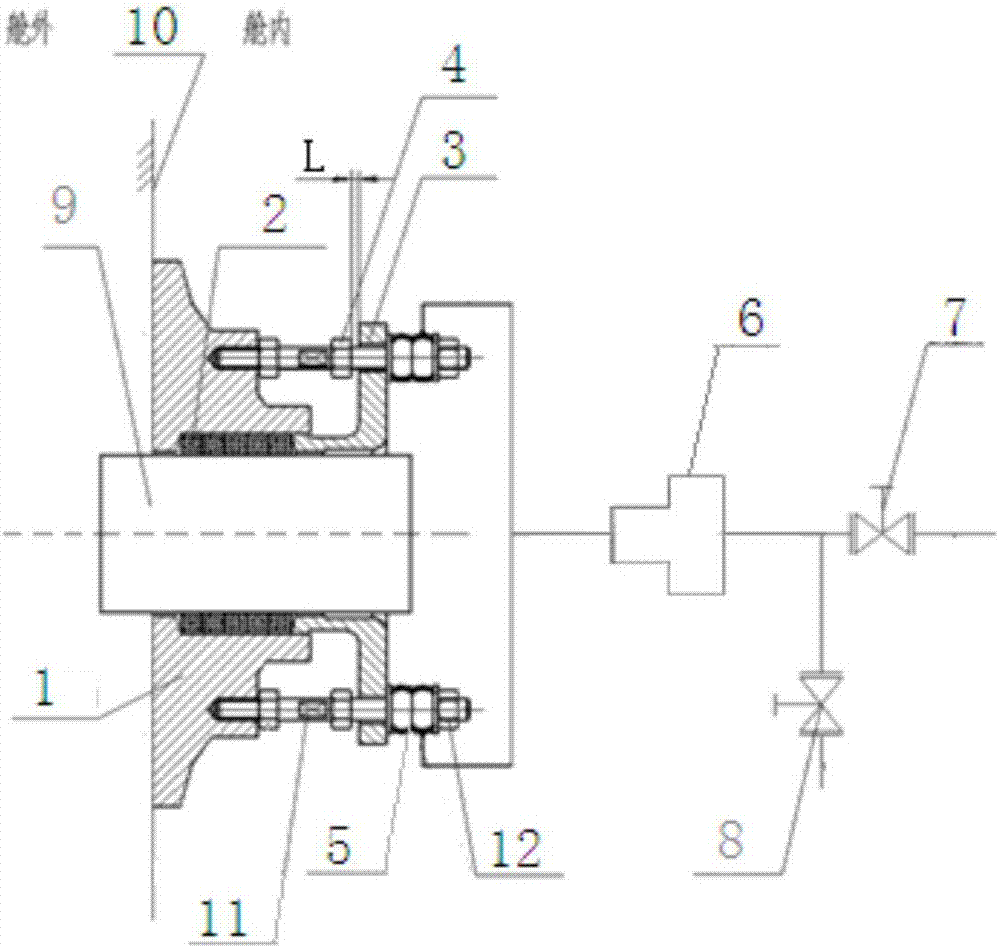

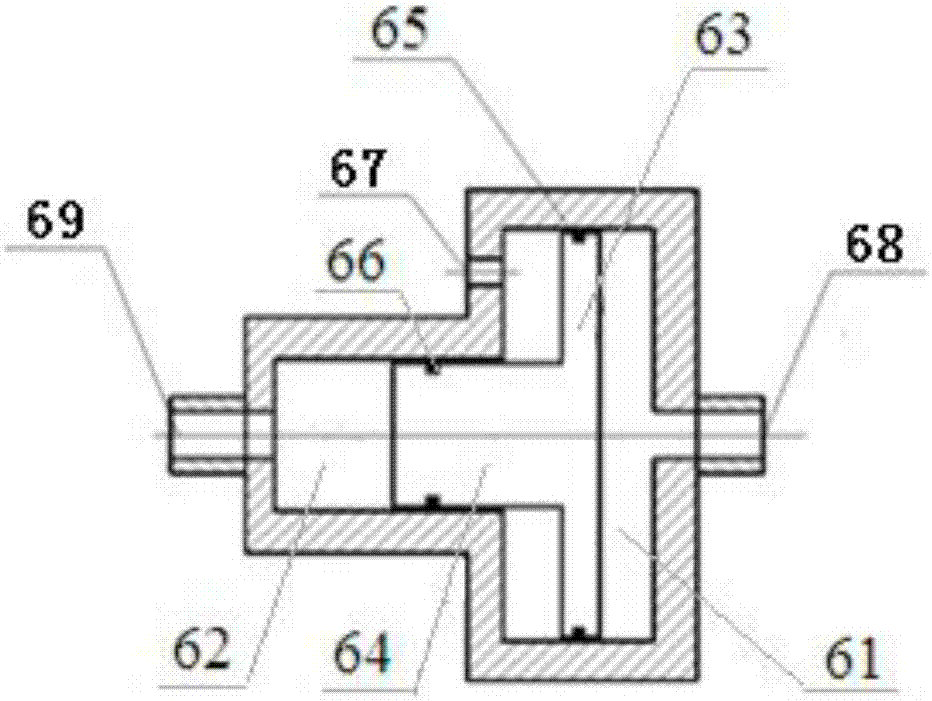

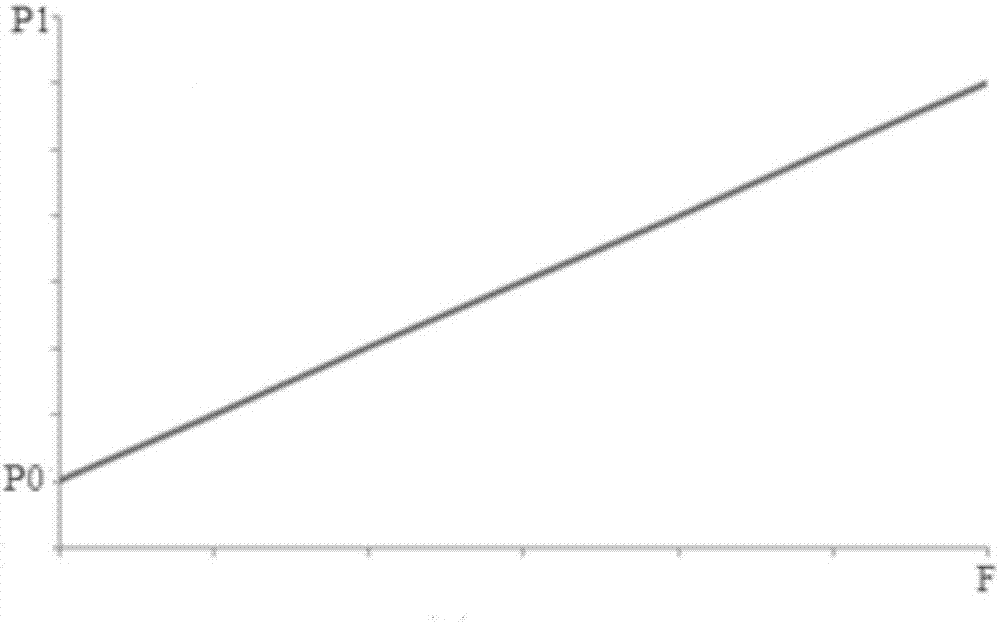

[0024] Such as figure 1 As shown, the present embodiment provides a sealing packing compaction device for adapting to the pressure of the environmental medium, including a stuffing box 1, the stuffing box 1 is fixed to the bulkhead 10 of the hull, the stuffing box 1 is provided with a stepped through hole, and the rotating shaft 9 passes through Through the step through hole and form a filling cavity with the step through hole, the sealing packing 2 is filled in the filling cavity; a pressing disc 3 is installed on the inner side of the stuffing box 1 corresponding to the filling cavity, and the central through hole of the pressing disc 3 A flange is provided on the inner end surface to match the filling cavity. A fixed guide rod 11 is installed on the outer periphery of the step through hole inside the stuffing box 1. The fixed guide rod 11 is connected with the pressing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com