Display panel, preparation method of display panel, and display device

A display panel and substrate technology, which is applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problems of complex manufacturing process of display panel, residual image of display panel, and low production capacity, so as to improve surface anchoring force, improve residual image and residual Effects of shadow and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

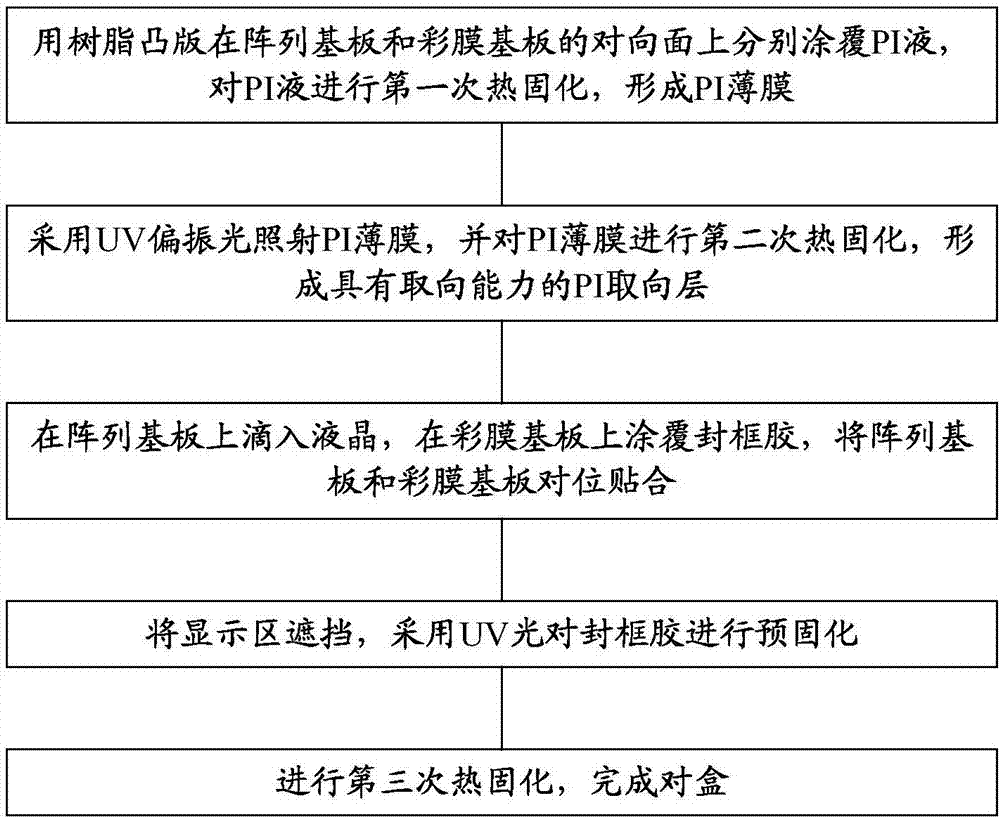

[0025] figure 1 It is a schematic flow chart of a manufacturing method of a display panel in the prior art. The main description of the process is as follows:

[0026] Use a resin letterpress to coat the PI liquid on the opposite surfaces of the array substrate and the color filter substrate, and heat-cure the PI liquid for the first time to form a PI film; irradiate the PI film with UV polarized light, and perform a second heat curing on the PI film. Secondary thermal curing to form a PI orientation layer with orientation ability; drop liquid crystal on the array substrate, coat the sealant on the color filter substrate, align and bond the array substrate and the color filter substrate; block the display area, use The UV light pre-cures the frame sealant; the third heat curing is performed to complete the box alignment.

[0027] The research of the inventors found that compared with the rubbing alignment method in the prior art display panel preparation method, the photo-al...

no. 1 example

[0042] Firstly, polyimide films are respectively formed on the opposite surfaces of the first substrate and the second substrate. Specifically, it includes: coating the PI liquid on the opposite surfaces of the first substrate and the second substrate with a resin relief plate, and performing the first heat curing on the PI liquid, so as to separately coat the PI liquid on the opposite surfaces of the first substrate and the second substrate. Form PI film.

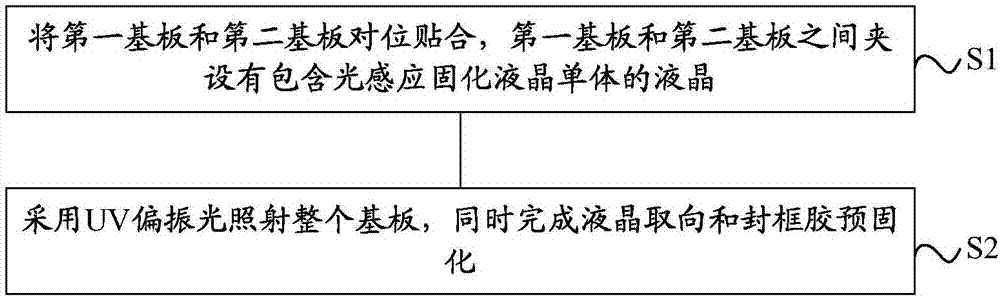

[0043] Secondly, the first substrate and the second substrate are aligned and bonded, and the liquid crystal containing the photosensitive curable liquid crystal monomer is sandwiched between the first substrate and the second substrate. It specifically includes: coating the sealant on the first substrate or the second substrate, dripping liquid crystal containing light-induced curable liquid crystal monomers on the first substrate or the second substrate; aligning the first substrate and the second substrate fit. The fr...

no. 2 example

[0049] Based on the inventive concepts of the aforementioned embodiments, the embodiments of the present invention provide a display panel, which is prepared by using the aforementioned embodiments. The display panels include Twisted Nematic (TN) type, Vertical Alignment (VA) type, In Plane Switching (IPS) and Fringe Field Switching (FFS) type display panels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com