Biaxially oriented polypropylene film for capacitor, metal laminated film, and film capacitor

A technology of metal laminated film and biaxial orientation, which is applied in the direction of fixed capacitor dielectric, capacitor, metal layered products, etc., can solve the problems of poor winding property, reduced capacitor life, and reduced capacitor withstand voltage, so as to achieve suitable processing Excellent performance, excellent voltage resistance, and excellent processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

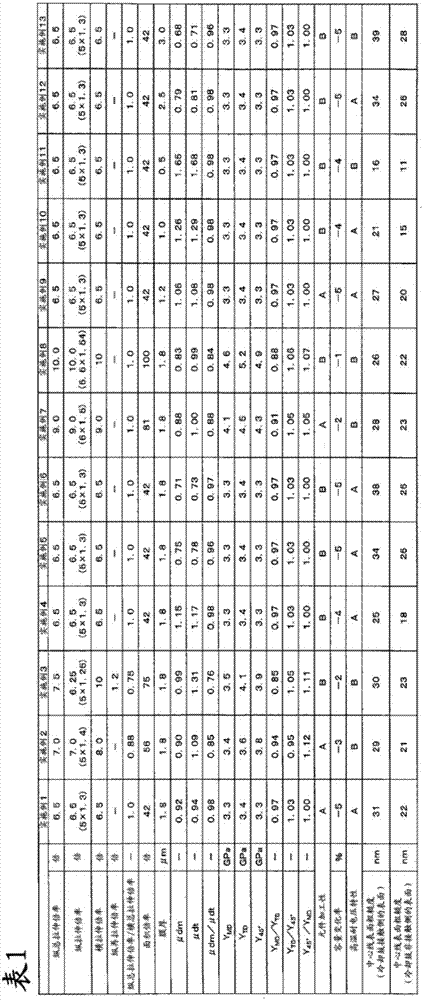

Embodiment 1

[0182] As linear polypropylene, a polypropylene resin manufactured by Prime Polymer Co., Ltd. with an isotactic pentad fraction of 97.9% and a melt flow index (MFR) of 2.6 g / 10 minutes was supplied to a temperature of 250° C. The extruder melts and extrudes from a T-shaped slit die into a sheet at a resin temperature of 250°C. On a cooling drum with a diameter of 1m that has been kept at 90°C, the temperature of the air knife is 90°C and the air speed is 140m. / s to cool and solidify the molten sheet. Next, the sheet was passed between rolls maintained at a temperature of 145° C. and provided with a peripheral speed difference, and multi-stage stretching was carried out along the longitudinal direction. The first stretch was to 5.0 times, and the second stretch was to 1.3 times. times, stretching to 6.5 times in total. At this time, in the orientation part of the 1st stage, it stretched by supplementing heat with the output of 4.0 kW using the radiation heater. Next, the fil...

Embodiment 2

[0184] As linear polypropylene, a polypropylene resin manufactured by Prime Polymer Co., Ltd. with an isotactic pentad fraction of 97.9% and an MFR of 2.6 g / 10 minutes was supplied to an extruder at a temperature of 250° C. The temperature is 250°C, and it is melted and extruded into a sheet form from a T-shaped slot die, and is melted at an air knife temperature of 90°C and an air velocity of 140m / s on a cooling drum with a diameter of 1m kept at 90°C. The sheet cools and solidifies. Next, the sheet was passed between rolls maintained at a temperature of 148° C. and provided with a peripheral speed difference, and stretched in multiple stages along the longitudinal direction, stretching to 5.0 times for the first time, and stretching to 1.4 times for the second time. times, stretching to 7.0 times in total. At this time, in the orientation part of the 1st stage, it stretched by supplementing heat with the output of 7.0 kW using the radiation heater. Next, the film was intro...

Embodiment 3

[0186] As linear polypropylene, a polypropylene resin manufactured by Prime Polymer Co., Ltd. with an isotactic pentad fraction of 97.9% and an MFR of 2.6 g / 10 minutes was supplied to an extruder at a temperature of 250° C. The temperature is 250°C, and it is melted and extruded into a sheet form from a T-shaped slot die, and is melted at an air knife temperature of 90°C and an air velocity of 140m / s on a cooling drum with a diameter of 1m kept at 90°C. The sheet cools and solidifies. Next, the sheet was passed between rolls maintained at a temperature of 148°C and provided with a peripheral speed difference, and multi-stage stretching was performed along the longitudinal direction, the first stretching was to 5.0 times, and the second stretching was to 1.25 times. times, stretching to 6.25 times in total. At this time, in the orientation part of the 1st stage, it extended|stretched by supplementing heat with the output of 5.0 kW using a radiation heater. Next, the film was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com