Alga control method for conch filament culture process of Porphyra haitanensis

A technology of shell filaments and altar laver, which is applied in the fields of botanical equipment and methods, cultivation, plant cultivation, etc., can solve the problems of shell filament damage, affecting survival rate, and cannot be widely promoted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

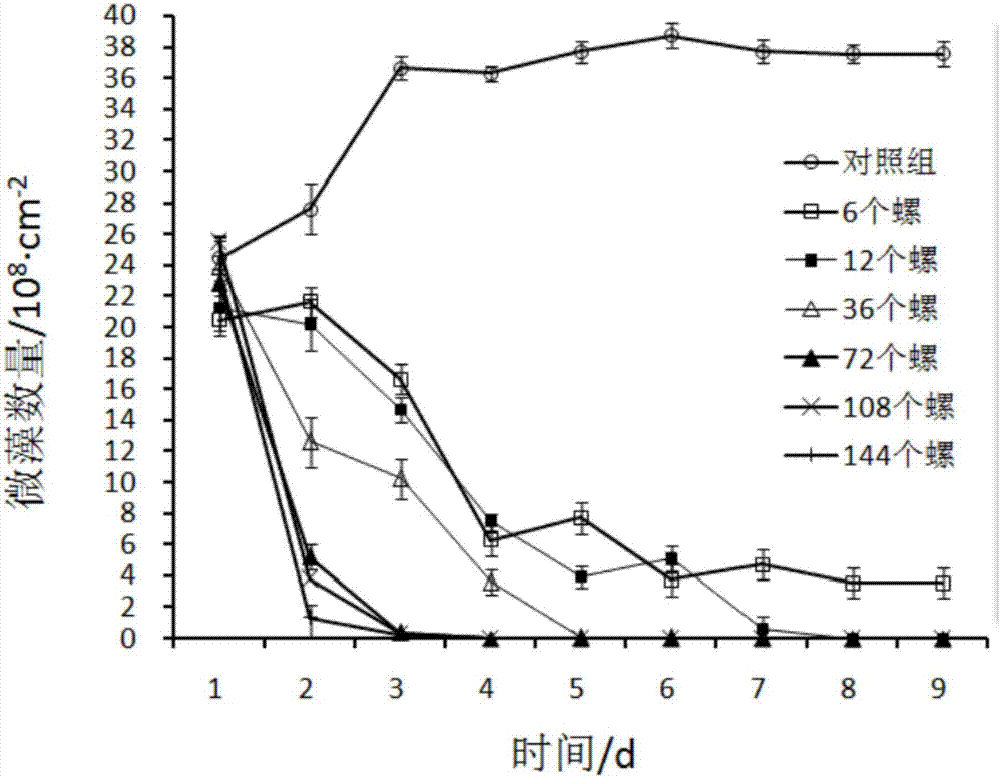

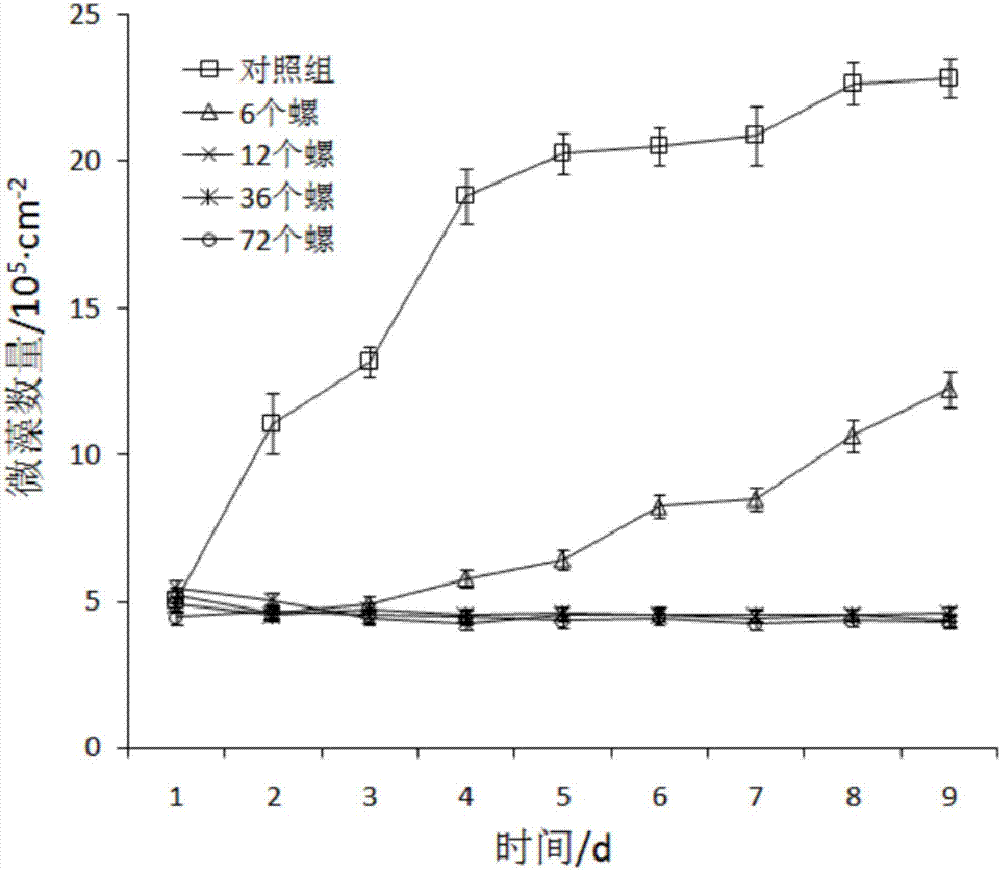

[0039] Embodiment: Step 1, selection and processing of snails: 108 single-toothed snails are embedded in every square meter, and 1×10 snails are used before putting in. -5 g / ml potassium permanganate solution was used to treat the surface of the snails for 5 minutes, and the selected snails were all starved for 24 hours, and the snails were emptied of feces;

[0040] Step 2, throwing in snails: throwing in single-dented snails when obvious algae adheres to the surface of the nursery shells;

[0041] Step 3, algae removal stage: in the first 3 days after the single-dentate snail is put in, the feces of the single-dentate snail is treated at least once a day, and the feces treatment uses a shower to spray and rinse the surface of the seedling shells;

[0042] Step 4, maintenance stage: 3 days after the single-dentate snails are put in, reduce the number of single-dentate snails to 12 per square meter, and carry out the feces treatment of the single-dentate snails on the next day...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com