Tofu skin production and preparation assembly line

An assembly line and bean curd technology, which is applied in the field of bean curd production and preparation lines, can solve the problems of inability to store for a long time, high water content of bean curd, and low efficiency, and achieve the effect of simple structure, low water content, and guaranteed production and preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] In order to achieve the purpose of the present invention, in some embodiments of the bean curd production and preparation line,

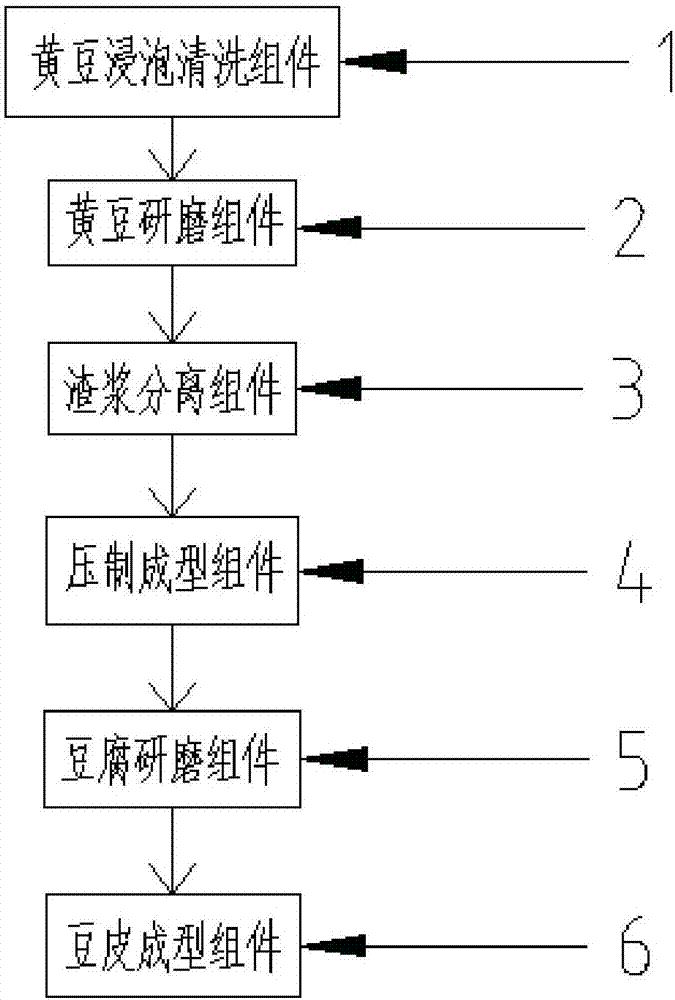

[0041] The bean curd production and preparation line includes in turn:

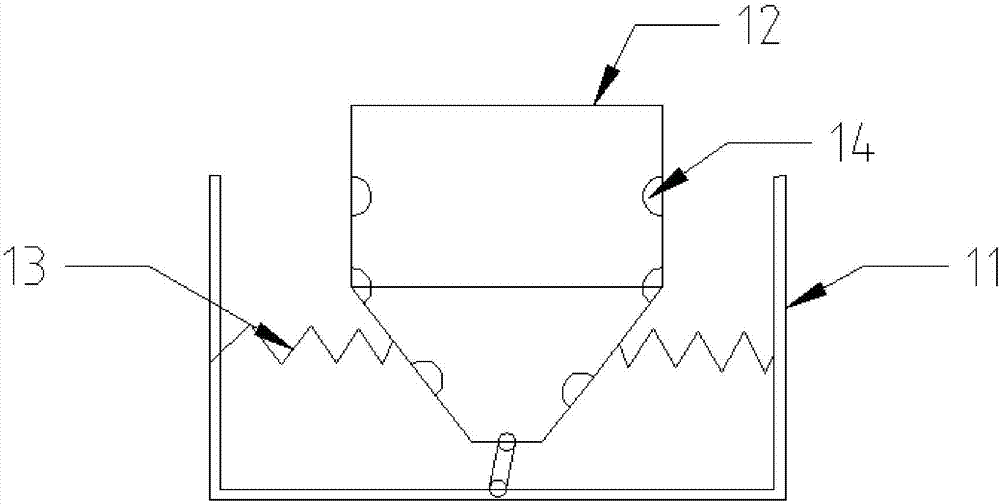

[0042] Soybean soaking and cleaning component 1, used for soaking and cleaning soybeans;

[0043] soybean grinding assembly 2, used for grinding soybeans;

[0044] The slurry separation component 3 is used to separate the ground soybeans from the slurry;

[0045] Pressing and molding assembly 4, used to press the soya bean milk after ordering into tofu;

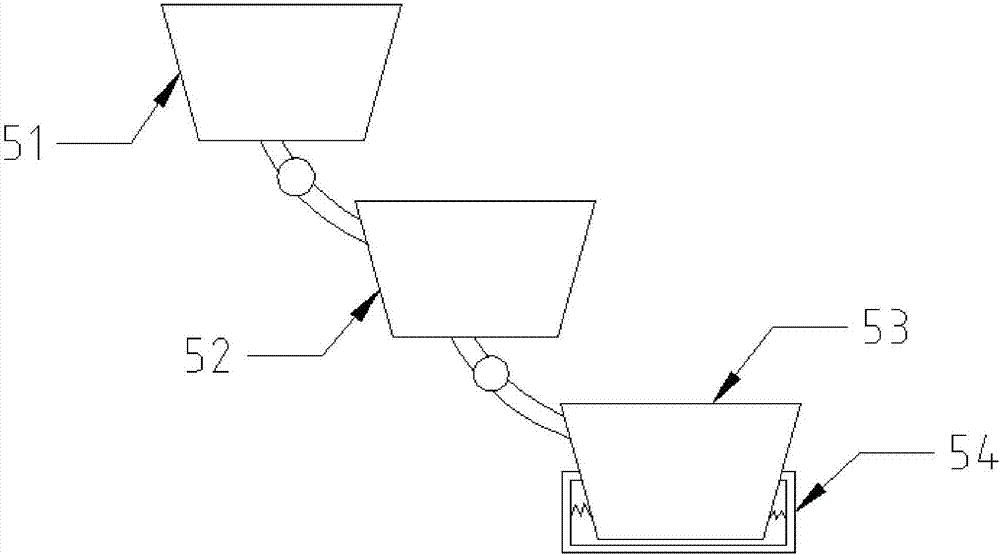

[0046] The tofu grinding assembly 5 is used to grind the tofu into bean curd paste;

[0047] Bean curd forming assembly 6 is used to make bean curd paste into bean curd.

[0048] The invention has a simple structure, each component performs its own duties, can effectively ensure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com