Preparation method and application of caustic soda

A technology of caustic soda and refined table salt is applied in the field of sodium hydroxide preparation to achieve the effects of improving preparation concentration and purity and ensuring preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

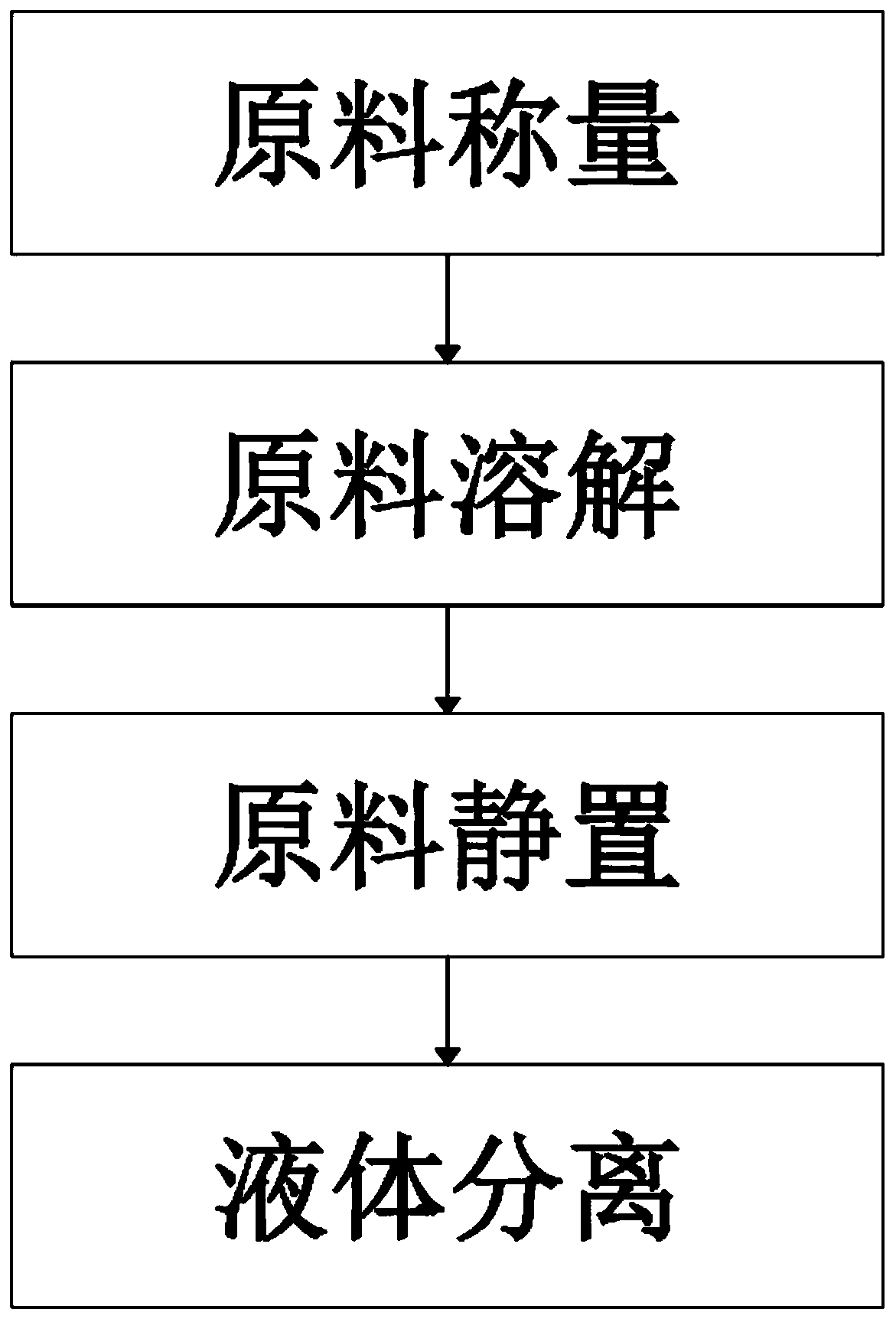

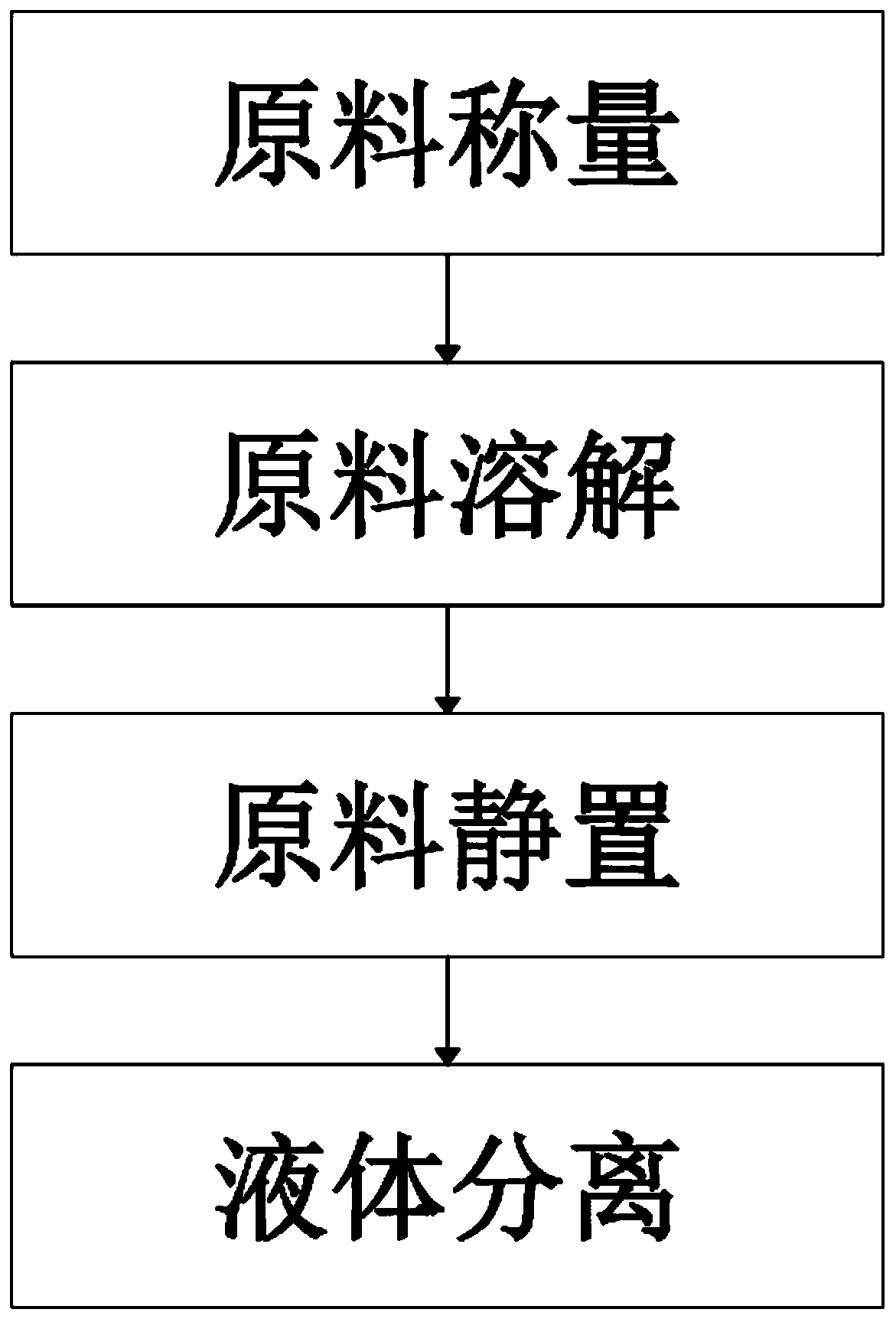

[0019] see figure 1 , the present invention provides a technical solution: a preparation method and application of caustic soda, the steps of the preparation method and application of caustic soda are as follows:

[0020] S1: Weighing of raw materials: The ingredients of the raw materials are as follows according to mass proportion, 50-80 parts of refined table salt, 50-80 parts of ammonium bicarbonate, 30-50 parts of quicklime, 30-50 parts of anticaking agent, and some distilled water;

[0021] S2: Dissolution of raw materials: Dissolve refined table salt in distilled water to prepare saturated salt water. After standing for 1-2 hours, when salt crystals precipitate at the bottom, add ammonium bicarbonate to prepare fresh sodium bicarbonate, filter out sodium bicarbonate, and then Add quicklime to water, wait for 2-3 hours, and generate fresh calcium hydroxide. Calcium hydroxide is a slurry of calcium hydroxide solution. The generation time is less than 10-30 minutes. Ammoniu...

Embodiment 1

[0025] A kind of preparation method and application about caustic soda, the steps of this preparation method and application about caustic soda are as follows:

[0026] S1: Weighing of raw materials: The ingredients of the raw materials are, according to the mass proportion, 50 parts of refined salt, 50 parts of ammonium bicarbonate, 30 parts of quicklime, 30 parts of anticaking agent, and some distilled water;

[0027] S2: Dissolution of raw materials: Dissolve refined table salt in distilled water to prepare saturated salt water. After standing for 1-2 hours, when salt crystals precipitate at the bottom, add ammonium bicarbonate to prepare fresh sodium bicarbonate, filter out sodium bicarbonate, and then Add quicklime to water, wait for 2 hours, and generate fresh calcium hydroxide. Calcium hydroxide is a slurry of calcium hydroxide solution. The generation time is less than 10 minutes. Ammonium bicarbonate is directly mixed with calcium hydroxide or passed through ammonia ga...

Embodiment 2

[0031] A kind of preparation method and application about caustic soda, the steps of this preparation method and application about caustic soda are as follows:

[0032] S1: Weighing of raw materials: The ingredients of the raw materials are as follows according to mass proportion, 65 parts of refined salt, 60 parts of ammonium bicarbonate, 45 parts of quicklime, 40 parts of anticaking agent, and some distilled water;

[0033] S2: Dissolution of raw materials: Dissolve refined table salt in distilled water to prepare saturated salt water. After standing for 1 hour, when the salt crystallizes at the bottom, add ammonium bicarbonate to prepare fresh sodium bicarbonate, filter out sodium bicarbonate, and then put quicklime Add it into water and wait for 2.5 hours to generate fresh calcium hydroxide. Calcium hydroxide is a slurry calcium hydroxide solution. The generation time is less than 10 minutes. Ammonium bicarbonate is directly mixed with calcium hydroxide or stored with ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com