Preparation method of MEMS pressure-sensitive film based on concentrated boron doping

A pressure-sensitive film, concentrated boron technology, applied in the process of producing decorative surface effects, coupling of optical waveguides, measuring fluid pressure, etc., can solve the problems of capacitance measurement error, large resistivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

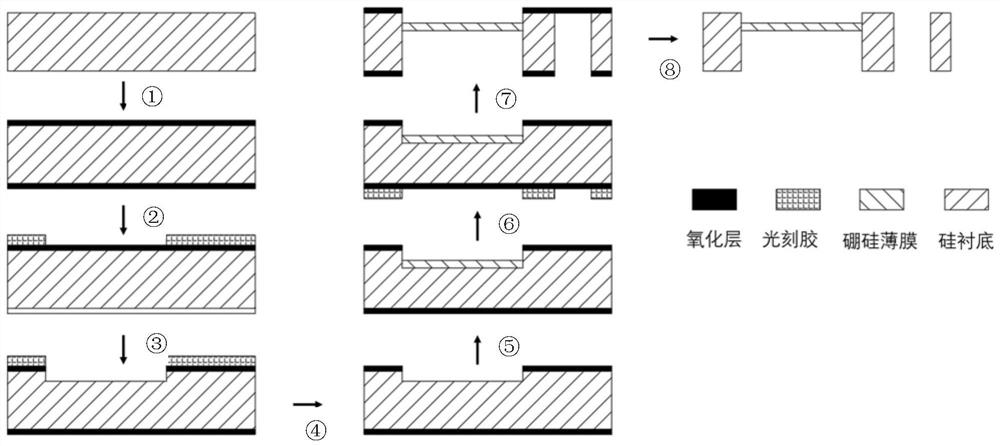

[0021] A method for preparing a MEMS pressure-sensitive thin film based on concentrated boron doping provided by the invention, the manufacturing process is as follows: figure 1 As shown, it specifically includes the following steps:

[0022] Step 1. Use the configured cleaning solution to clean the silicon wafer. The silicon wafer after cleaning is as follows: figure 1 Shown in number ①.

[0023] The cleaning solution includes No. 1 liquid, No. 2 liquid and No. 3 liquid. Among them, No. 1 liquid is a mixture of ammonia water, hydrogen peroxide and deionized water, and the ratio is ammonia water: hydrogen peroxide: deionized water = 1:1:5; No. 2 The liquid is a mixture of nitric acid, hydrogen peroxide and deionized water, the ratio is nitric acid: hydrogen peroxide: deionized water = 1:1:5; No. 3 liquid is a mixture of concentrated sulfuric acid, hydrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com