Modular multistage chromatography column as well as sampling method and separating method thereof

A modular, chromatographic column technology, applied in separation methods, chemical instruments and methods, sampling devices, etc., can solve problems such as low utilization rate, high operational difficulty, and high cost, achieving strong practicability and high flexibility. , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: dynamic monitoring - atmospheric pressure sampling in the column

[0035]Atmospheric pressure sampling in the column uses the principle of liquid pressure. By rotating the relative position of the upper and lower cylinders at the nesting place, the lower sampling hole of the upper cylinder is aligned with the upper sampling hole of the lower cylinder. The liquid in the column is Flow out under high pressure for sampling. In order to reduce solvent loss, fast rotation is required to reduce the time when two sampling holes are facing each other.

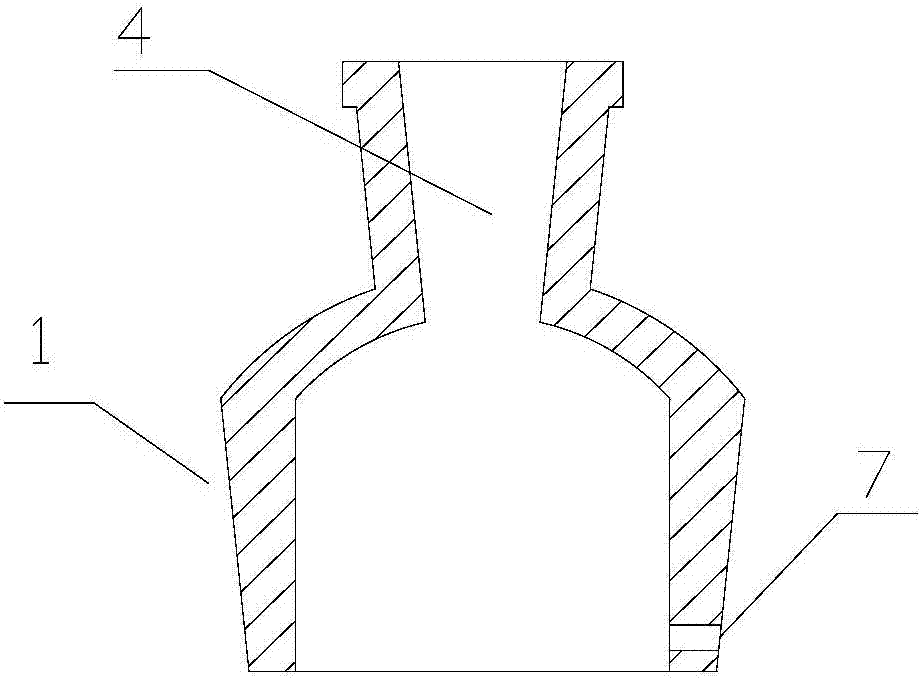

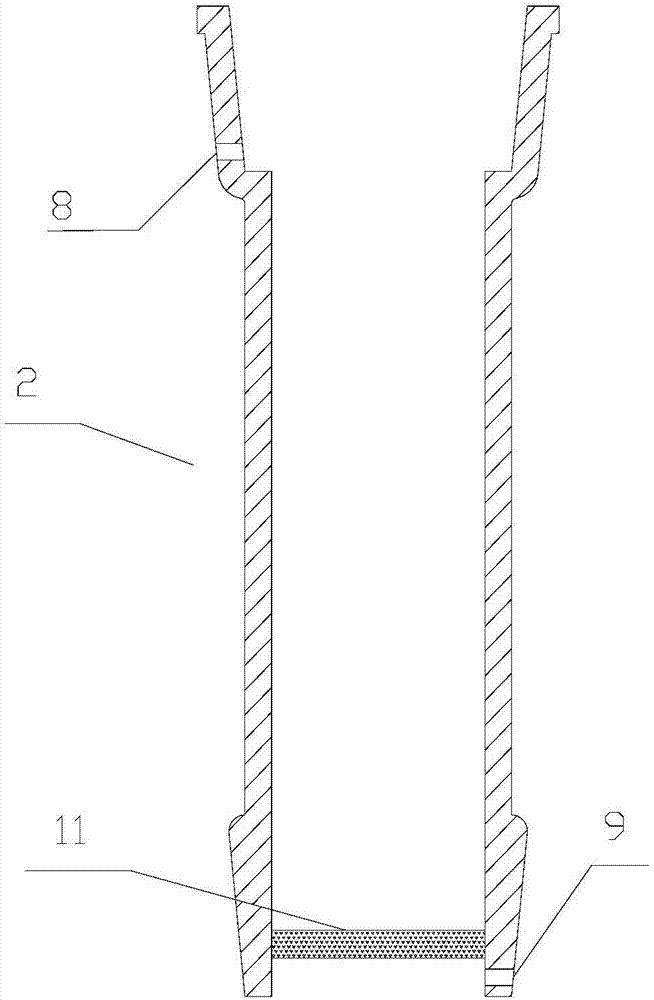

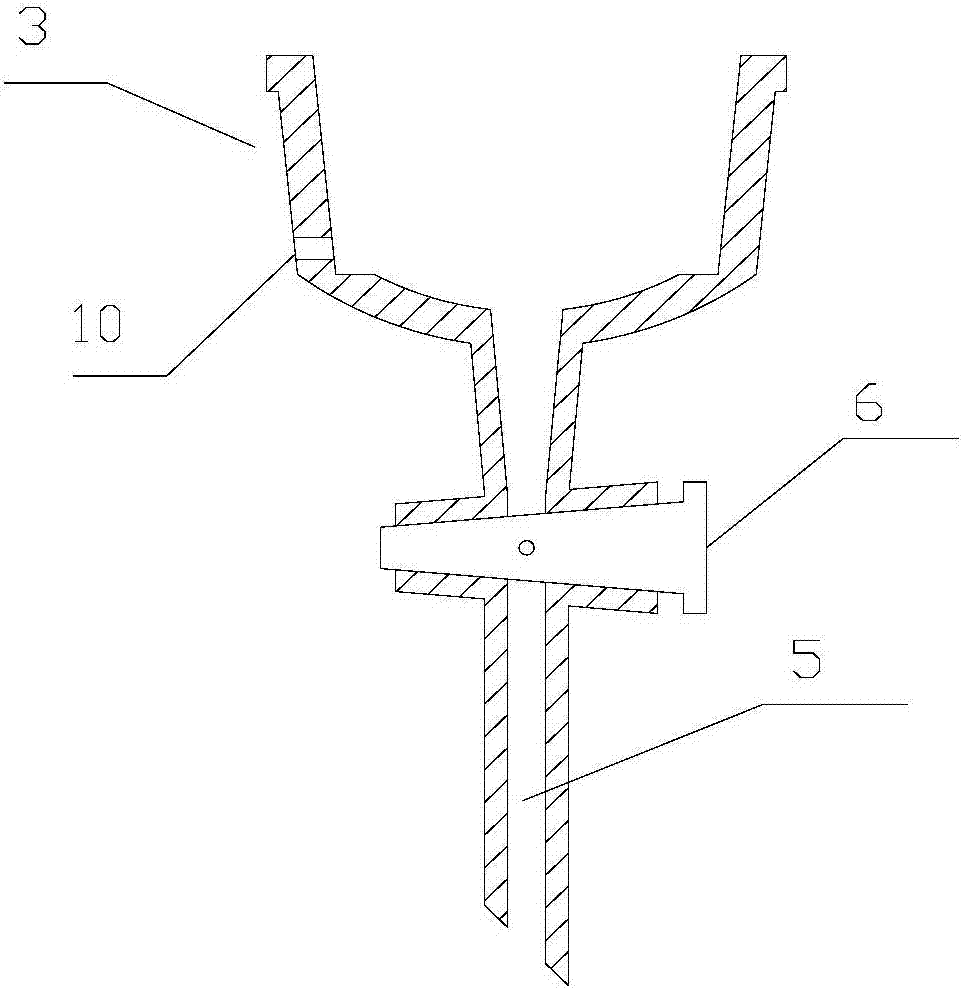

[0036] Such as Figure 4 As shown in Fig. 1, taking 3 columns combined to form a three-stage chromatography column as an example, the cross-sectional view of the nesting part of the 2nd column and the 3rd column is shown in Figure 5 . This embodiment includes: column top 1, 3-section column body 2 and column bottom 3, the nesting surfaces of each module are mated to ensure airtightness, and lubricants are applie...

Embodiment 2

[0039] Example 2: Dynamic monitoring - negative pressure sampling in the column

[0040] Negative pressure sampling in the column. Before sampling, add a corresponding ground plug to the nesting place on the top of the column to seal it, and then let the solvent continue to flow out from the liquid outlet at the bottom of the column. At this time, the cavity above the solvent in the chromatography column generates negative pressure. , when the liquid at the bottom of the column drips slowly, the control valve at the bottom of the column is closed. At this time, the pressure generated by the negative pressure in the cavity above the solvent is enough to balance most of the solvent gravity. The small hole is opposite and communicated with the atmosphere. The negative pressure of the cavity above the solvent and the atmospheric pressure outside the small sampling hole slow down the outflow rate of the solvent at the small sampling hole, and quickly rotate the upper and lower colum...

Embodiment 3

[0043] Embodiment 3: free combination-column separation

[0044] Before the separation of the column, a sealed ground plug is added to the top of the column, and at the same time, the solvent continues to flow out of the liquid outlet until it is completely stopped, that is, a complete negative pressure can be formed above the liquid in the column, and the pressure difference generated by the negative pressure in the column is the same as The gravity of the liquid in the entire chromatography column is balanced. At this time, the control valve at the bottom of the column is closed. When the sampling holes of each stage are connected to the atmosphere, the pressure difference formed at the sampling holes is greater than the gravity of the liquid above the sampling holes. At this time Air will enter the nesting place below the sand core at the sampling hole, and the part above the sampling hole can be separated as a whole. The solvent above the sand core will be due to the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com