Cellulose microsphere sewage filter and filtration method

A technology of cellulose microspheres and sewage filters, applied in gravity filters, chemical instruments and methods, loose filter material filters, etc., can solve the problems of low precision, inconvenient disassembly, and heavy mechanical filters, etc., to achieve filtration High precision, low head loss, and wide operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

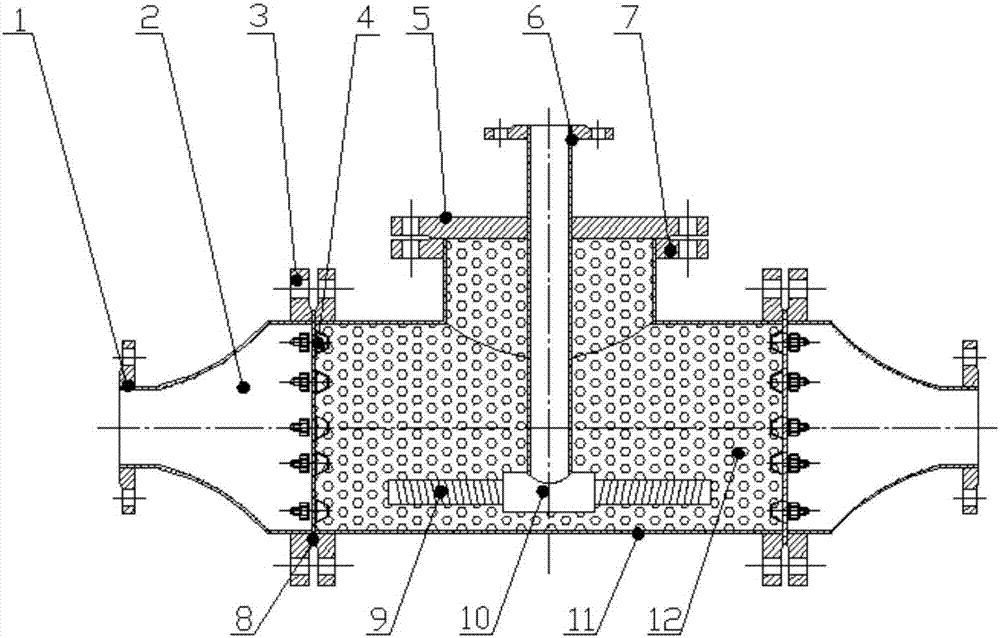

[0027] Attached below figure 1 The two-dimensional structure diagram describes the filter of this embodiment in detail. The equipment is mainly composed of water inlet 1, variable diameter 2, DN250 flange 3, permeable cap 4, blind flange 5, flushing inlet flange 6, filler port flange 7, water distribution plate 8, screen pipe 9, flushing pipe 10. Cylinder body 11, fiber ball filler 12 and other parts. The filter element is realized in the following way: according to the characteristics of the treated sewage and the adsorption characteristics of various microspheres, adjust the mass percentage of various cellulose microspheres in the filter element, and directly fill it in this implementation after mixing. In the filter designed as an example, it is used in the field of water treatment with deep filtration requirements.

[0028] Before the filter works, at first the water inlet and outlet valves need to be closed, and then the fiber ball filler 12 is added to the feed bin fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com