Conveying process casting-rolling joining method used for directly rolling rectangular billets

A conveying process, square and rectangular technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of long distance between continuous casting machine and rolling mill, excessive temperature drop of billet, and inability to realize rapid blanking of billet, etc. Achieve the effect of improving production efficiency, reducing temperature drop, and ensuring fast and normal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

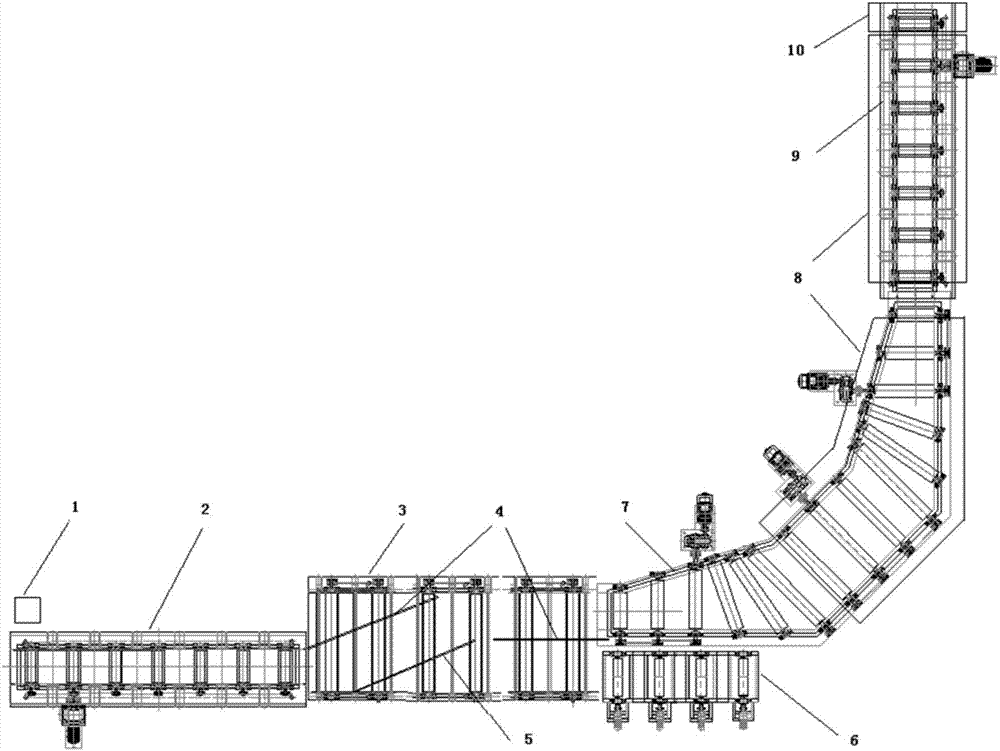

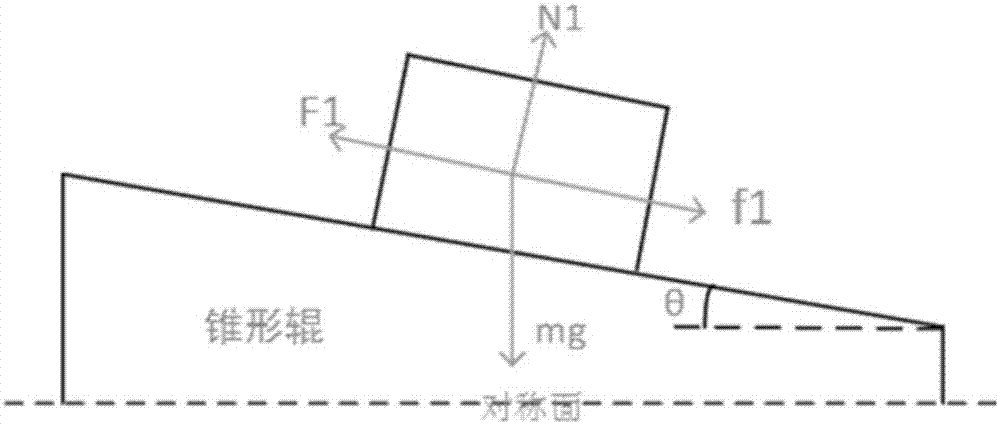

[0041] For the transformation of the direct rolling process production line of a certain factory, the layout of the casting and rolling joints of the production line is as follows image 3 As shown, among them, the radius of the arc-shaped turning roller table is 20m, the speed of the arc-shaped turning roller table is 2m / s, the horizontal inclination angle of the tapered roller of the arc-shaped turning roller table is 5°, and the horizontal lifting angle is 10°. The continuous casting slab turns at 90°; the conveying speed of the straight roller table is 0.5~2m / s, and the speed is adjustable; the power of the induction heating device at the end of the straight roller table before the rolling mill is 1500kW, the power frequency is 1000HZ, and the length is 3m; the turning roller table and the subsequent conveying roller table are buckled with heat preservation covers, and the inside of the heat preservation cover is a heat insulation board made of nanoporous materials.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com