Safety protection type glass transfer robot

A handling robot and safety protection technology, applied in manipulators, program-controlled manipulators, chucks, etc., can solve the problems of inability to protect the life safety of workers, low work efficiency, and easy damage to glass, and achieve low labor and high work efficiency. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with specific embodiments, but at the same time, it is explained that the scope of protection of the present invention is not limited to the specific scope of this embodiment. Based on the embodiments of the present invention, those of ordinary skill in the art have not made creative work premises. All other embodiments obtained below belong to the protection scope of the present invention.

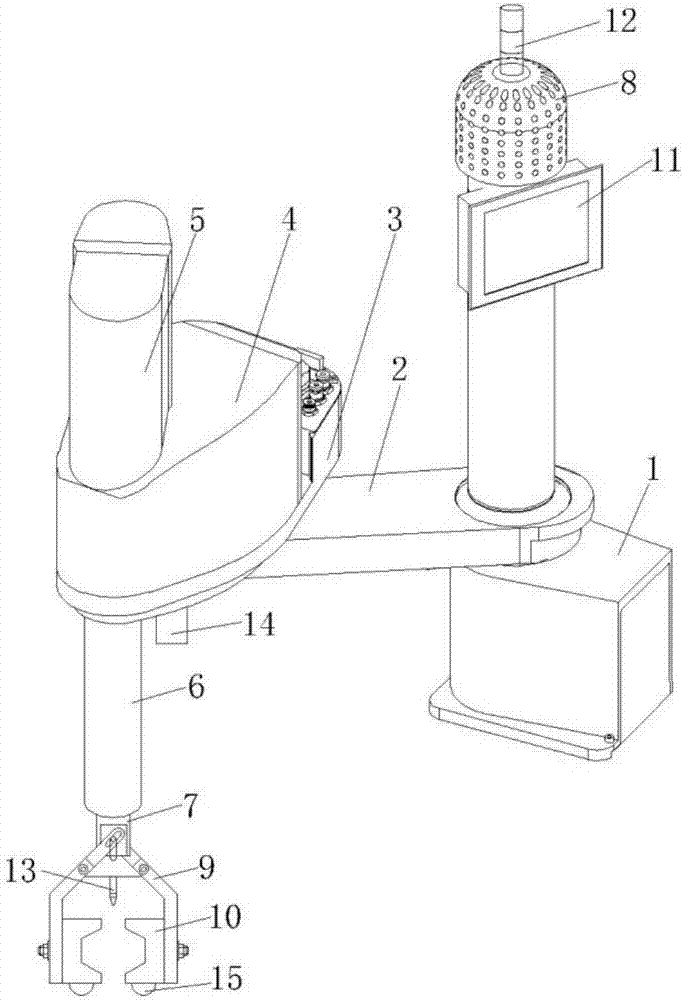

[0023] Such as figure 1 As shown, a safety protection glass handling robot of this embodiment includes a body 1, a first joint shaft 2, a second joint shaft 3, a connecting seat 4, a cylinder 5, a telescopic sleeve 6, a coupling 7, Sonar sensor 8, clamping mechanism 9, V-shaped block 10, PLC controller 11, sound and light alarm 12, cleaning mechanism 13, visual inspection mechanism 14, and laser head 15.

[0024] The connection relationship of the above-mentioned components is as follows: the two ends of the first j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com