Novel car anti-roll bar

A technology of anti-roll bars and automobiles, which is applied to vehicle components, elastic suspensions, interconnection systems, etc., and can solve the problems of increased weight of anti-roll bars, single function of anti-roll bars, large cross-sectional size and weight, etc., and achieves reduction Effects on quality, improved driving stability and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

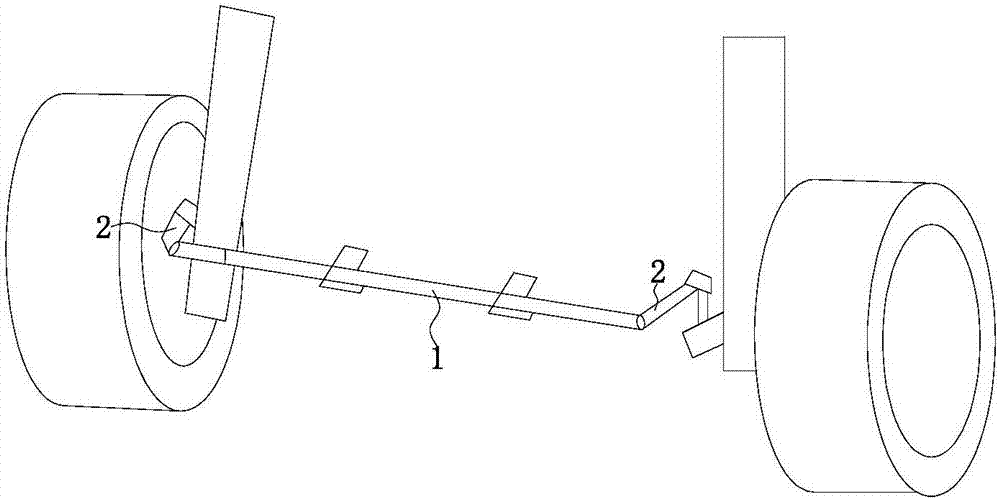

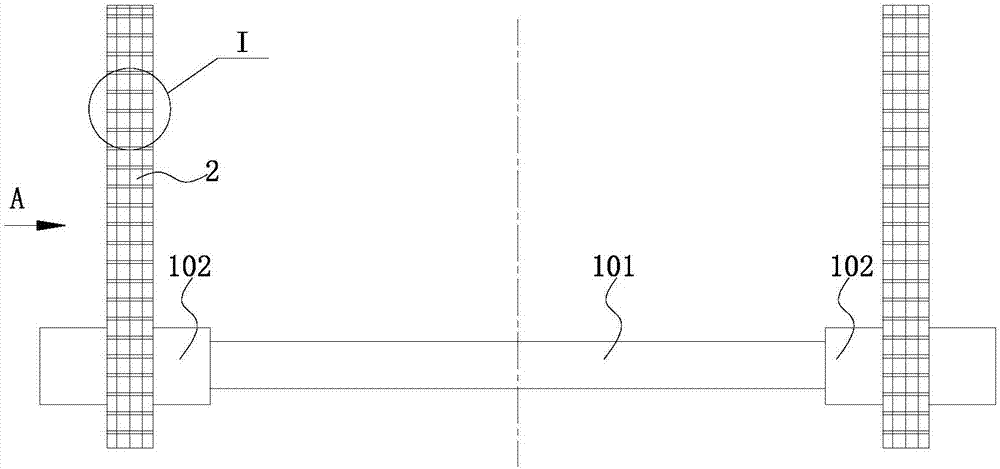

[0035] Such as Figure 1-Figure 10 A novel automobile anti-roll bar shown includes a torsion bar 1 horizontally arranged below the vehicle frame along the transverse direction of the automobile. The torsion bar 1 includes a rod body 101, and a connecting sleeve 102 is respectively arranged at both ends of the rod body 101. The rod body 101 is connected to the vehicle body. The frames are connected by two or more bearings, so that the rod body 101 can rotate freely relative to the frame;

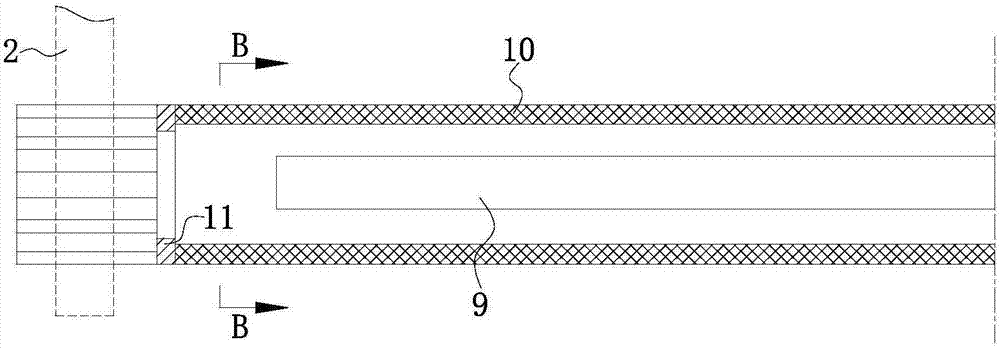

[0036]One end of the connecting sleeve 102 passes through the side of one end of the connecting arm 2 and can make the connecting arm 2 rotate a certain angle along the axis of the connecting sleeve 102, and the other end of the connecting arm 2 is connected with the swing arm of the automobile suspension through a ball joint. The connecting arm 2 is formed by stacking a plurality of parallel connecting layers 20 along the thickness direction of the connecting arm 2, the connecting layer 20 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com