Motorized integrated anchoring chassis

A chassis and mooring technology, applied in balloon aircraft and other directions, can solve the problems of many required personnel, long deployment and erection time, construction and deployment difficulties, etc., to improve environmental adaptability and battlefield survivability, and to solve layout and transportation overruns , the effect of safe and reliable transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

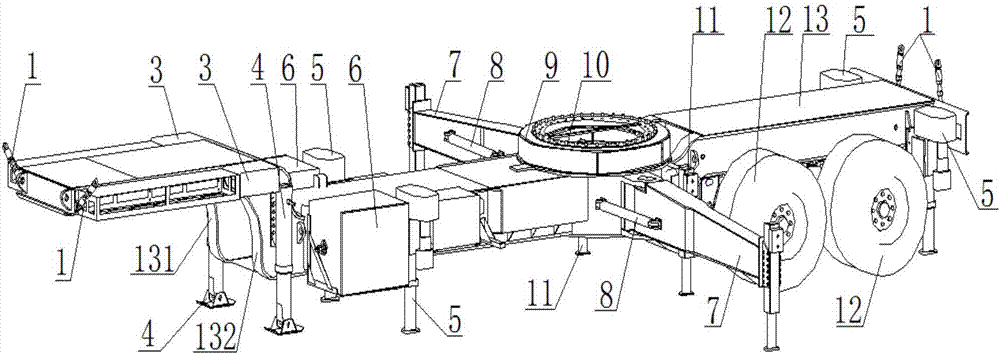

[0042] see figure 1 , a motorized integrated mooring chassis, including four locking screws 1, two accessory boxes 3, two front legs 4, four self-leveling legs 5, two cable boxes 6, two overturning braces Leg 7, two support leg fixing rods 8, protective cover 9, slewing bearing 10, two load-bearing support legs 11, axle tire 12 and chassis longitudinal beam 13.

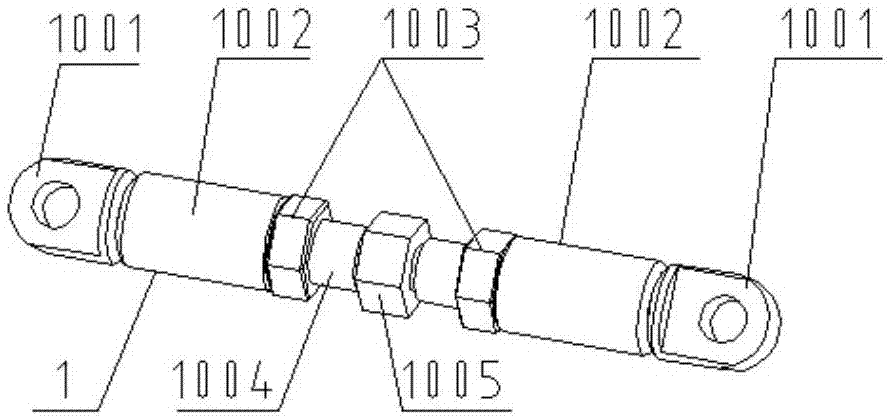

[0043] see figure 2 , the locking screw 1 includes two single ears 1001 , two sleeves 1002 , two limit nuts 1003 , screw rod 1004 , and fixed nut 1005 . Both ends of the locking screw 1 are respectively connected with a single ear 1001, one end of the single ear 1001 is a cylindrical member with external thread, and the other end is a single fork ear structure with a round hole in the center. The sleeve 1002 is a round pipe structure with internal thread, which is used to connect and fix the external thread of the single ear 1001. The limit nut 1003 is installed on the threaded rod 1004 for limiting and fixing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com