Method for preparing calcium carbide smelting raw material by jet coal powder and quick lime powder

A technology of quicklime powder and long-flame coal, applied in the direction of carbide, calcium carbide, etc., can solve the problems of waste, low utilization efficiency, low efficiency of production methods, etc., and achieve the effect of improving the average compressive strength and realizing effective utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

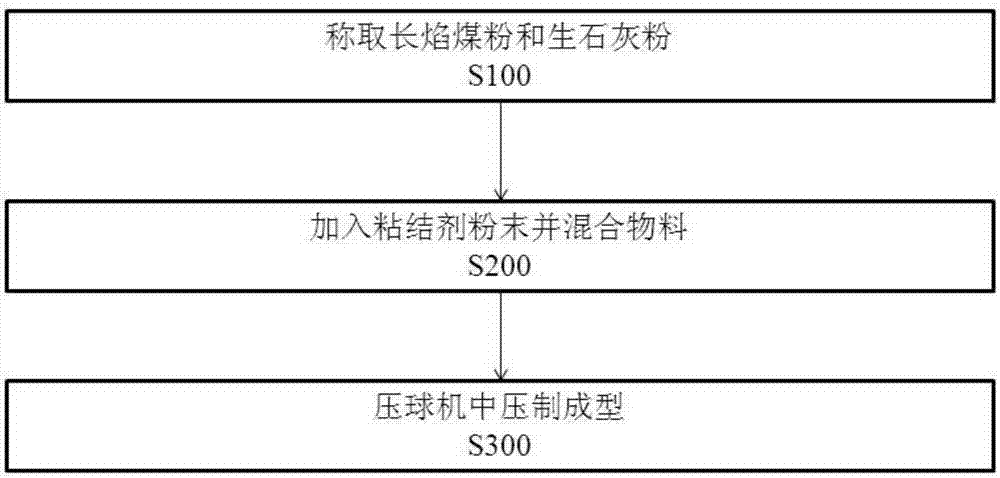

[0021] A method for preparing calcium carbide smelting raw materials from long-flame coal powder and quicklime powder. First, weigh a certain amount of long-flame coal powder and quicklime powder to form a mixture in step S100, so that the mass ratio of the two is 0.92:1, and then in step S200 Add binder powder accounting for 10% of the mass of the mixture, the size of the binder powder is 100 mesh, mix the above materials evenly, and the mixing time is 10 minutes; in step S300, put the above mixed materials into a briquetting machine for compression molding , The pressure of the ball press is set to 19MPa. Among them, the size of long-flame coal powder, quicklime powder and binder powder is ≤100 mesh.

[0022] The binder is mainly modified low-density polyethylene thermoplastic waste plastic powder, and its preparation method is: after cleaning the waste low-density polyethylene plastic, put it into a crusher, crush it to a size of 100 mesh fine particles, and then heat up M...

Embodiment 2

[0025] A method for preparing calcium carbide smelting raw materials from long-flame coal powder and quicklime powder. First, weigh a certain amount of long-flame coal powder and quicklime powder to form a mixture in step S100, so that the mass ratio of the two is 0.92:1, and then in step S200 Add binder powder accounting for 20% of the mass of the mixture, the size of the binder powder is 100 mesh, mix the above materials evenly, and the mixing time is 15 minutes; in step S300, put the above mixed materials into a briquetting machine for compression molding , The pressure of the ball press is set to 21MPa. Among them, the size of long-flame coal powder, quicklime powder and binder powder is ≤200 mesh.

[0026] The binder is mainly modified low-density polyethylene thermoplastic waste plastic powder, and its preparation method is: clean the waste low-density polyethylene plastic, put it into a crusher and crush it into small particles with a size below 1mm, and then heat up to...

Embodiment 3

[0029] A method for preparing calcium carbide smelting raw materials from long-flame coal powder and quicklime powder. First, weigh a certain amount of long-flame coal powder and quicklime powder to form a mixture in step S100, so that the mass ratio of the two is 0.92:1, and then in step S200 Add binder powder accounting for 15% of the mass of the mixture, the size of the binder powder is 200 mesh, mix the above materials evenly, and the mixing time is 12 minutes; in step S300, put the above mixed materials into a ball press machine and press Forming, the pressure of the ball press is set to 20MPa. Among them, the size of long-flame coal powder, quicklime powder and binder powder is ≤200 mesh.

[0030] The binder is mainly modified low-density polyethylene thermoplastic waste plastic powder. The preparation method is to clean the waste low-density polyethylene plastic, put it into a crusher and crush it into a powdery material with a size of about 200 mesh, and then heat it u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com