A kind of high-melt-strength polypropylene grafted with heteroaromatic ring derivatives and its preparation method

A high-melt-strength, heteroaromatic-ring technology applied in the field of polypropylene resins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

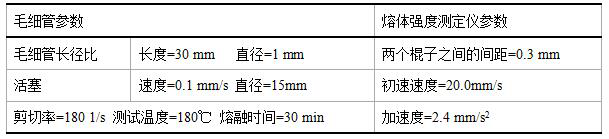

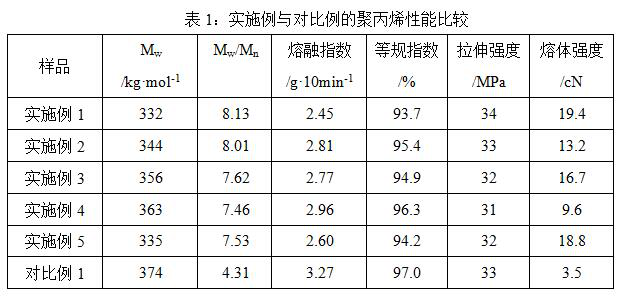

[0030] Weigh 1000 g polypropylene, 1 g antioxidant 1010, 0.5 g antioxidant 168, 1 g calcium stearate, 0.6 g nucleating agent hydroxyaluminum p-tert-butylbenzoate, 0.5 g DHBP, 20 g 3-pyridine -1,1-Difluoropropene, mix in a mixer for 20min until uniform. Add the mixture to a twin-screw extruder with L / D=40 and Φ of 35mm, the screw speed is 60 r / min, the feeding speed is 4kg / h, and the rotation number of the extruder is set at 15 rpm . The extruder is divided into four heating zones, the temperature of the first heating zone is set at 175°C, the temperature of the second heating zone is set at 190°C, the temperature of the third heating zone is set at 200°C, and the temperature of the fourth heating zone is set at 200°C , extruded and granulated to obtain long-chain branched polypropylene resin pellets with high melt strength. Some samples were taken for performance testing and melt strength determination. The results are shown in Table 1.

Embodiment 2

[0032] Weigh 1000 g polypropylene, 2 g antioxidant 1010, 1 g antioxidant 168, 1 g calcium stearate, 0.6 g hydroxyaluminum p-tert-butylbenzoate, 0.5 g DHBP, 10 g 3-pyridine-1 , 1-dichloropropene, mixed in a mixer for 20min until uniform. The extrusion granulation process is the same as in Example 1.

Embodiment 3

[0034] Weigh 1000 grams of polypropylene, 1 gram of antioxidant 1076, 0.5 gram of antioxidant 168, 2 grams of erucamide, 0.6 gram of hydroxyaluminum p-tert-butylbenzoate, 0.5 gram of benzoyl peroxide, 20 gram of 2-(pyridine-2-methylene)malononitrile, mixed in a blender for 20min until uniform. The extrusion granulation process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com