Flow switching valve

A flow channel switching and valve shaft technology, applied in the direction of multi-way valves, valve devices, valve details, etc., can solve problems such as difficult miniaturization, pressure fluctuations, and opening area changes, and achieve shortening of the overall length and reduction of driving torque , the effect of simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

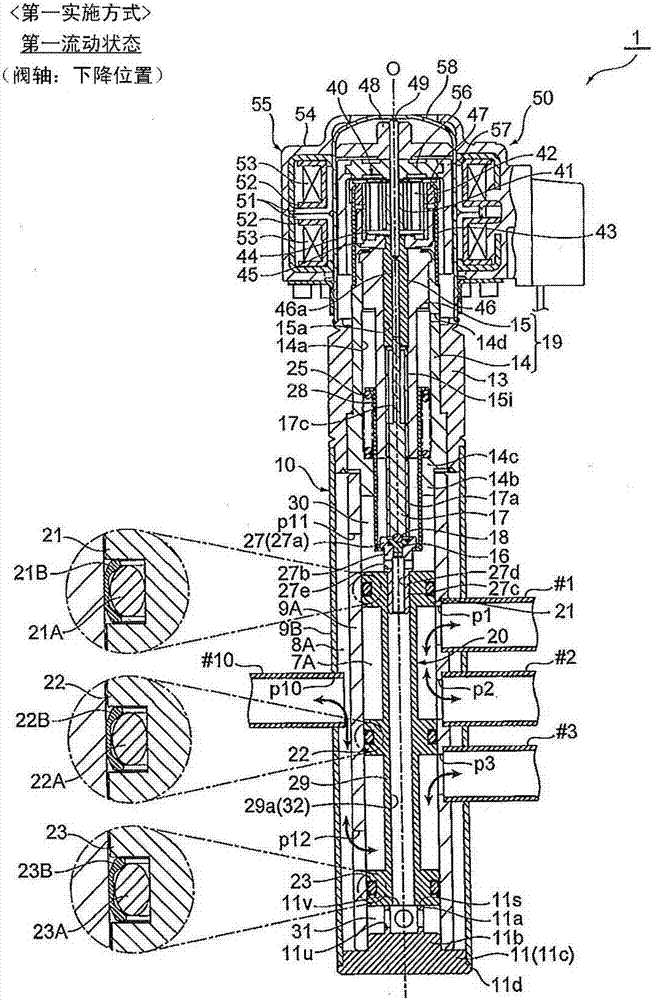

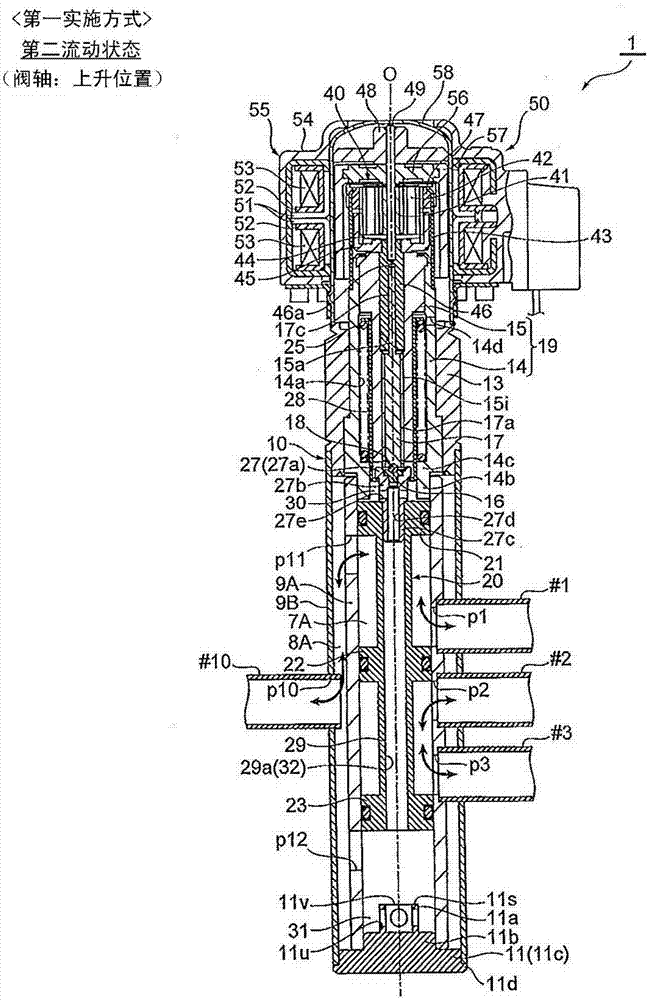

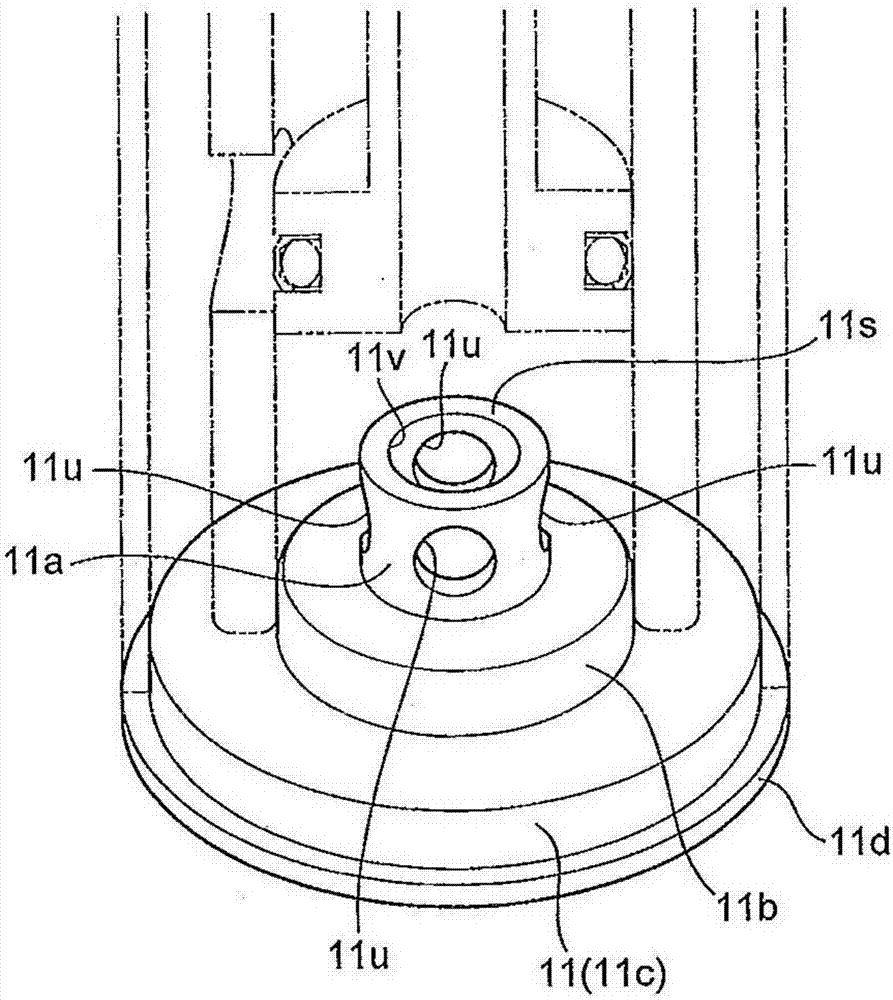

[0096] figure 1 and figure 2 It is a longitudinal sectional view showing the first embodiment of the channel switching valve of the present invention, figure 1 Indicates the first flow state (valve shaft: down position), figure 2 Indicates the second flow state (valve shaft: raised position).

[0097] In addition, in this specification, descriptions indicating positions and directions such as up and down, left and right, and front and rear are described in accordance with the drawings for convenience in order to avoid cumbersome description, and are not limited to the positions and directions in the actual use state.

[0098] In addition, in each figure, gaps formed between components, spacing distances between components, etc. are for ease of understanding of the invention and convenience of drawing, and may be drawn larger or smaller than the size of each component.

[0099] The flow path switching valve 1 of this embodiment is, for example, an electric multi-way switch...

no. 2 approach

[0127] Figure 4 and Figure 5 It is a longitudinal sectional view showing the second embodiment of the channel switching valve of the present invention, Figure 4 Indicates the first flow state (valve shaft: down position), Figure 5 Indicates the second flow state (valve shaft: raised position).

[0128] The flow path switching valve 2 of the second embodiment differs from the flow path switching valve 1 of the above first embodiment basically only in the number of inner ports formed in the inner casing and valve elements formed in the valve shaft. Therefore, configurations having the same functions as those in the first embodiment are assigned the same reference numerals and detailed description thereof will be omitted, and only the above-mentioned differences will be described in detail below.

[0129] The flow path switching valve 2 of this embodiment is a flow path switching valve used as a six-way switching valve in, for example, a heat pump type cooling and heating ...

no. 3 approach

[0138] Figure 8 and Figure 9 It is a longitudinal sectional view showing the third embodiment of the channel switching valve of the present invention, Figure 8 Indicates the first flow state (valve shaft: down position), Figure 9 Indicates the second flow state (valve shaft: raised position).

[0139]The channel switching valve 3 of the third embodiment is basically different from the channel switching valve 2 of the second embodiment above in the opening position of the outer port and the shape of the communication space between the outer case and the inner case. Therefore, the components having the same functions as those in the second embodiment are assigned the same reference numerals and detailed description thereof will be omitted, and only the above-mentioned differences will be described in detail below.

[0140] The flow path switching valve 3 of this embodiment is the same as the above-mentioned second embodiment, and is a flow path switching valve used as a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com