Method for preparing multi-shell hollow structure metal organic framework material

A metal-organic framework and hollow structure technology, which can be applied to 6/16 groups of organic compounds without C-metal bonds, organic chemistry, zinc-organic compounds, etc. Simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Synthesis of Metal Organic Framework MIL-101:

[0034] Add chromium nitrate nonahydrate (0.8g) and terephthalic acid (0.22g) into 5mL deionized water respectively, after stirring and dissolving chromium nitrate nonahydrate, add it to the aqueous solution of terephthalic acid, continue stirring for about 5 minutes, and mix The solution was transferred to a 50 ml polytetrafluoroethylene-lined reaction kettle, and then placed in an oven at 180°C for hydrothermal reaction for 4 hours. The resulting green product was centrifuged and washed with N,N-dimethylformamide and Wash twice with deionized water and dry to obtain green metal-organic framework MIL-101 solid powder, the size of the obtained MIL-101 is about 180nm;

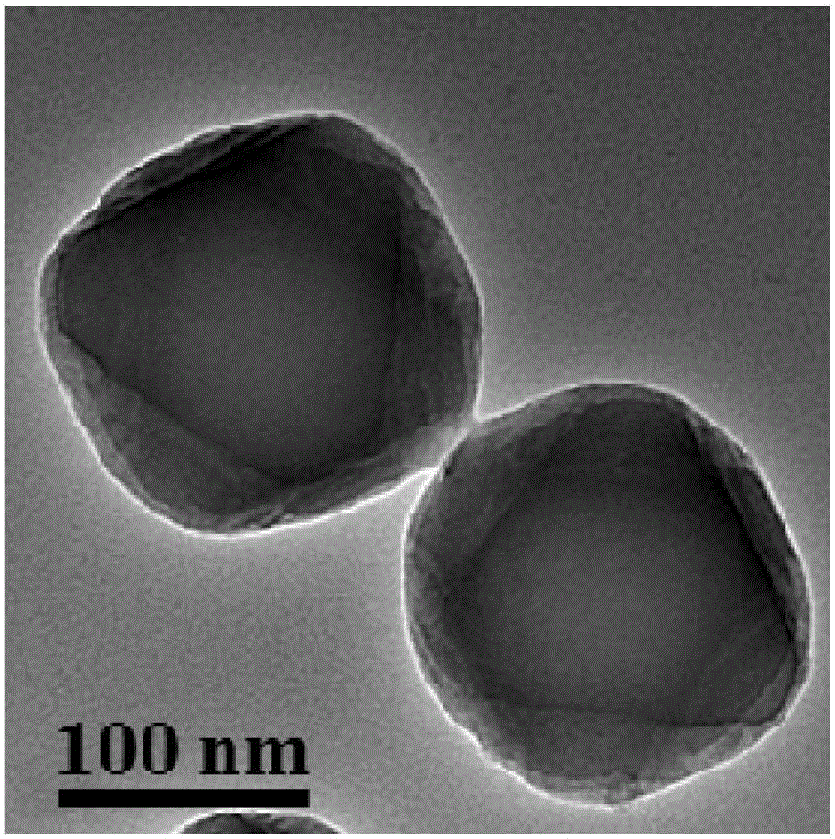

[0035] 2) Using proton solvent etching to obtain a single-layer hollow metal-organic framework MIL-101:

[0036] Disperse the above metal-organic framework MIL-101 into 20 mL of deionized water, take 5 mL of it and add it to a 50 mL polytetrafluoroethylen...

Embodiment 2

[0047] 1) Synthesis of Metal Organic Framework MIL-101:

[0048] Add chromium nitrate nonahydrate (0.4g) and terephthalic acid (0.11g) into 5mL deionized water respectively, after stirring and dissolving chromium nitrate nonahydrate, add it to the aqueous solution of terephthalic acid, continue stirring for about 5 minutes, and mix The solution was transferred to a 50 ml polytetrafluoroethylene-lined reaction kettle, and then placed in an oven at 180°C for hydrothermal reaction for 4 hours. The resulting green product was centrifuged and washed with N,N-dimethylformamide and Each was washed twice with deionized water, and after drying, a green metal-organic framework MIL-101 solid powder was obtained, and the obtained MIL-101 had a size of about 120 nm.

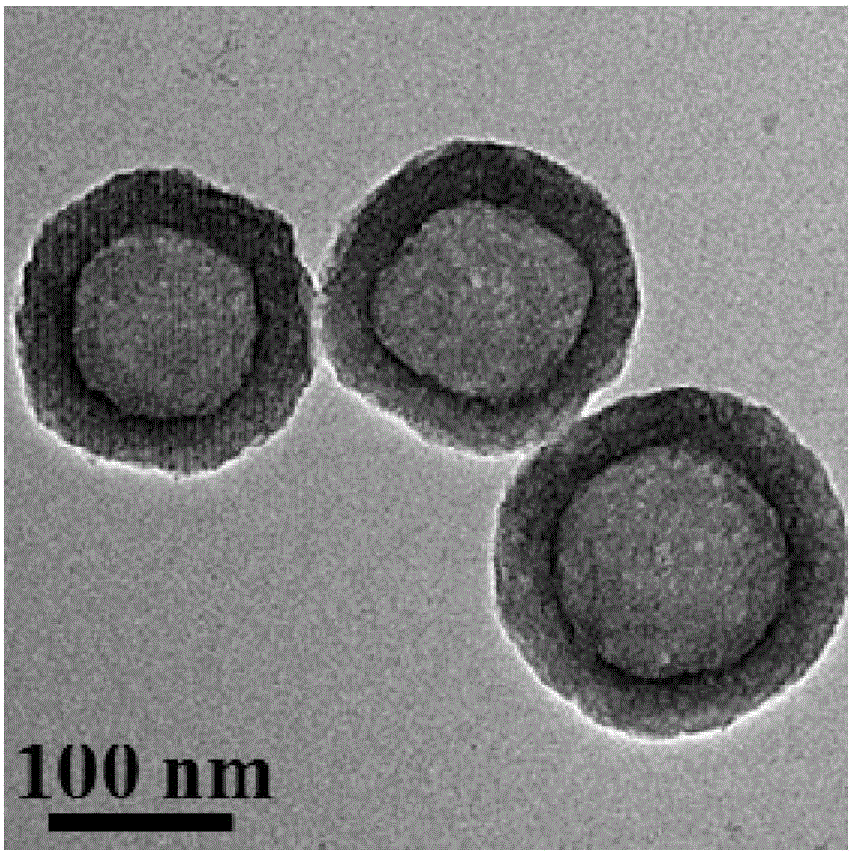

[0049] 2) Using proton solvent etching to obtain a single-layer hollow metal-organic framework MIL-101:

[0050] Disperse the above metal-organic framework MIL-101 into 20 mL of deionized water, take 5 mL of it and add it to...

Embodiment 3

[0057] 1) Synthesis of Metal Organic Framework MIL-101:

[0058] Add chromium nitrate nonahydrate (0.6g) and terephthalic acid (0.17g) into 5mL deionized water respectively, after stirring and dissolving chromium nitrate nonahydrate, add it to the aqueous solution of terephthalic acid, continue stirring for about 5 minutes, and mix The solution was transferred to a 50 ml polytetrafluoroethylene-lined reaction kettle, and then placed in an oven at 180°C for hydrothermal reaction for 4 hours. The resulting green product was centrifuged and washed with N,N-dimethylformamide and Each was washed twice with deionized water and dried to obtain a green metal-organic framework MIL-101 solid powder, and the size of the obtained MIL-101 was about 300 nm.

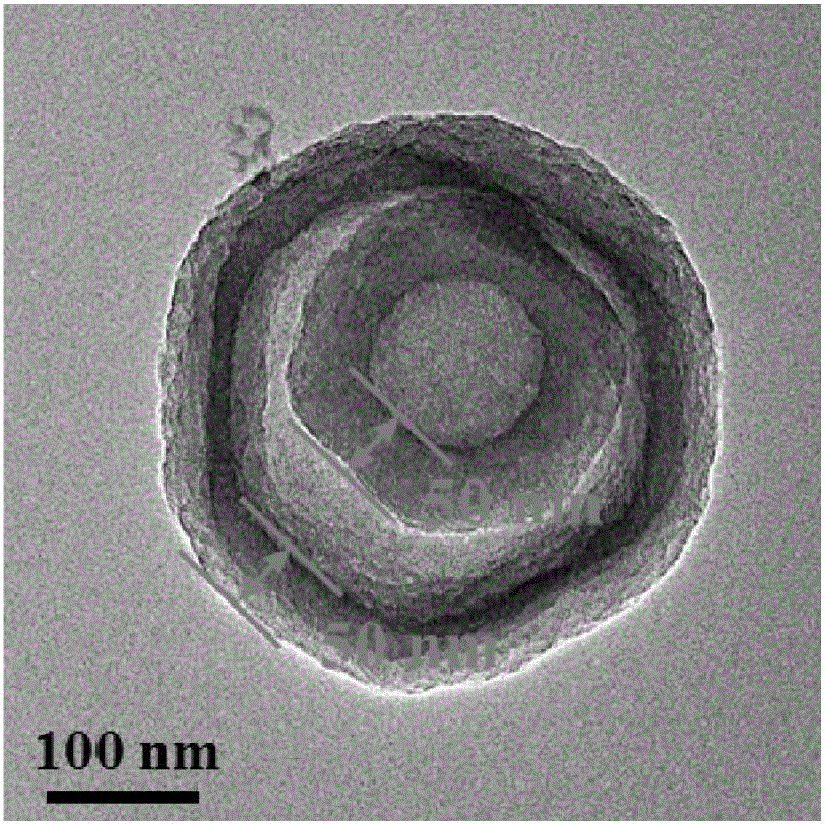

[0059] 2) Using proton solvent etching to obtain a single-layer hollow metal-organic framework MIL-101:

[0060] Disperse the above metal-organic framework MIL-101 into 20 mL of deionized water, take 5 mL of it and add it to a 50 mL p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com