Processing method of frozen cooked clear-water hairy crabs

A processing method and technology for hairy crabs, which are applied in the fields of freezing/cooling preservation of meat/fish, food science, etc., can solve the problem of limiting the sales season and sales radius of the hairy crab market, easily accumulating a large amount of harmful components of histamine, and reducing the edible value and economic value. and other issues to achieve the effect of maintaining flavor and nutritional content, good quality and taste, and eliminating regional and seasonal restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

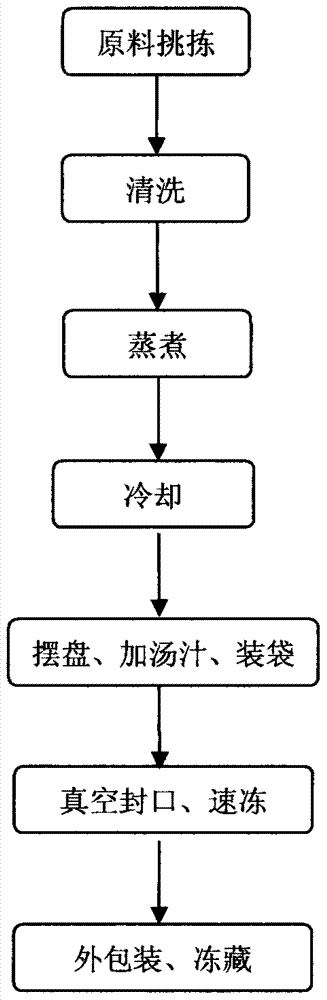

Image

Examples

Embodiment 1

[0021] The raw material is fresh hairy crabs with a specification of less than 100 grams. After cleaning, they are directly sent to the conveyor belt and sent to the cooking machine for cooking. The cooking temperature is 120°C, the cooking time is 8.5 minutes, and the center temperature of the hairy crab body is ≥75°C. The steamed hairy crabs are directly transferred from the normal temperature water cooling tank to the conveyor belt of the cooling water cooling tank, the cooling water temperature is 0°C, and the center temperature of the hairy crab body is controlled below 10°C. The cooled hairy crabs are graded, and then weighed and placed on a plate. The hairy crabs that have been placed on the plate are wrapped in sterilized packaging bags, and then the soup is automatically added with a soup gun, and then vacuum-sealed after adding the soup. Use a liquid nitrogen quick-freezing machine for quick-freezing, place the hairy crabs individually on the conveyor belt, and freez...

Embodiment 2

[0023] The raw materials are fresh hairy crabs with a specification of 100-125 grams. After cleaning, they are directly sent to the conveyor belt and sent to the cooking machine for cooking. The cooking temperature is 122 ° C, the cooking time is 10.5 minutes, and the center temperature of the hairy crab body is ≥ 75 ° C. The steamed hairy crabs are directly transferred from the normal temperature water cooling tank to the conveyor belt of the cooling water cooling tank, the cooling water temperature is 0°C, and the center temperature of the hairy crab body is controlled below 10°C. The cooled hairy crabs are graded, and then weighed and placed on a plate. The hairy crabs that have been placed on the plate are wrapped in sterilized packaging bags, and then the soup is automatically added with a soup gun, and then vacuum-sealed after adding the soup. Use a liquid nitrogen quick-freezing machine for quick-freezing, place the hairy crabs individually on the conveyor belt, and fre...

Embodiment 3

[0025] The raw material is fresh hairy crabs with a specification of 130-175 grams. After cleaning, they are directly sent to the conveyor belt and sent to the cooking machine for cooking. The cooking temperature is 125°C, the cooking time is 12 minutes, and the center temperature of the hairy crab body is ≥75°C. The steamed hairy crabs are directly transferred from the normal temperature water cooling tank to the conveyor belt of the cooling water cooling tank, the cooling water temperature is 0°C, and the center temperature of the hairy crab body is controlled below 10°C. The cooled hairy crabs are graded, and then weighed and placed on a plate. The hairy crabs that have been placed on the plate are wrapped in sterilized packaging bags, and then the soup is automatically added with a soup gun, and then vacuum-sealed after adding the soup. Use a liquid nitrogen quick-freezing machine for quick-freezing, place the hairy crabs individually on the conveyor belt, and freeze them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com