Application of sodium ibandronate, powder inhalation and preparation method

A technology of sodium ibandronate and powder spray, applied in the field of sodium ibandronate, can solve the problems of no inhalation dosage form and no respiratory system of sodium ibandronate, and achieve low systemic side effects, good safety, The effect of rapid metabolism in the blood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

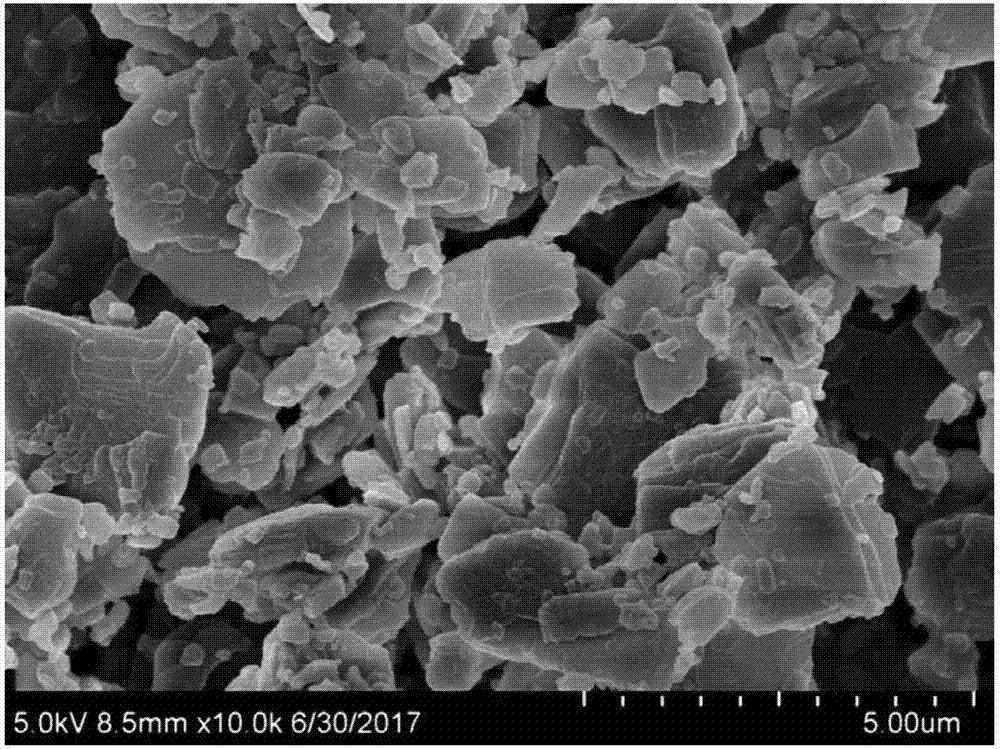

[0087] one step pulverization

[0088] Get 1000g of ibandronate sodium bulk drug, and load it into the QS100 pulverizer. The pulverization condition is 0.7MPa pulverization pressure, 2 hours, pulverization once, to obtain ibandronate sodium fine powder. Preliminary observation shows that the micropowder has no adhesion, no agglomerates, and is well dispersed.

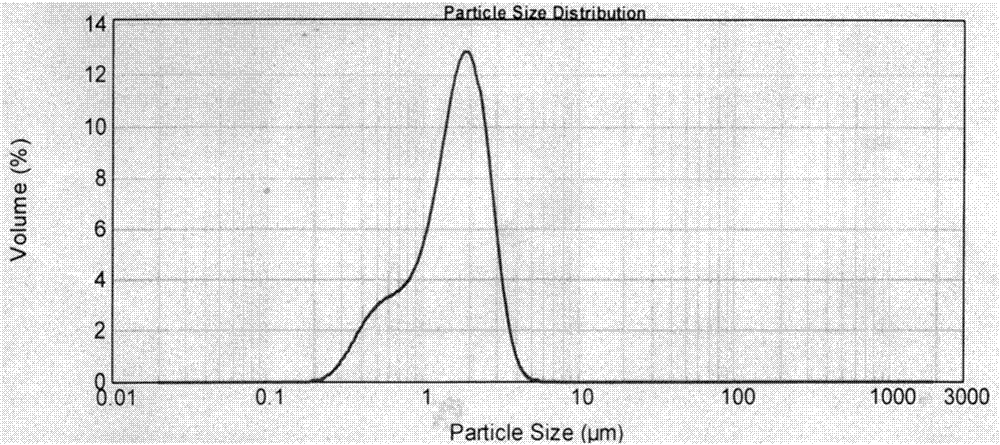

[0089] About 1g of the micropowder sample was taken, and the particle size of the micropowder powder was measured using a laser particle size analyzer from Malvern Instruments Ltd. in the United Kingdom. As a result, the particle size of the above sample was 5.55 μm for d90, 2.73 μm for d50, and 0.90 μm for d10.

[0090] In order to investigate whether the preparation process caused the destruction and degradation of sodium ibandronate, the raw material drug of sodium ibandronate before pulverization and the powder after pulverization were determined by molybdenum blue colorimetry. The method is to take 8 mg each of t...

Embodiment 2

[0092] two-step pulverization

[0093] Get 1000g of ibandronate sodium bulk drug, and load it into the QS100 pulverizer. The crushing condition is 0.7MPa crushing pressure, crushing twice. The first crushing time is 1.5 hours, and the second crushing time is 2 hours. Obtain ibandronate sodium micropowder. Preliminary observation shows that the micropowder has no adhesion, no agglomerates, and is well dispersed.

[0094] About 1g of the micropowder sample was taken, and the particle size of the micropowder powder was measured using a laser particle size analyzer from Malvern Instruments Ltd. in the United Kingdom. As a result, the particle size of the above sample was 2.73 μm for d90, 1.61 μm for d50, and 0.58 μm for d10.

[0095] In order to investigate whether the preparation process caused the destruction and degradation of sodium ibandronate, the raw material drug of sodium ibandronate before pulverization and the powder after pulverization were determined by molybdenum ...

Embodiment 3

[0097] spray drying

[0098] Dissolve 0.5g of ibandronate sodium in 200ml of water, 2.5g of ammonium bicarbonate in 100ml of water, mix the 2 solutions, then add 200ml of ethanol and mix to form a 40% ethanol aqueous solution for spraying. Ammonium bicarbonate is completely degraded and volatilized during the spray drying process, so that small pores are formed in the finally formed ibandronate sodium solid micropowder.

[0099]B-290 spray dryer, equipped with 0.7mm 2-liquid nozzle. The conditions are: inlet temperature 160°C, 100% suction, feed rate 15ml / min, spray rate 500L / h. Dry powder samples were stored in a desiccator at room temperature. The outlet temperature is about 70°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com