Anti-corrosion and abrasion resisting device of piston material pushing centrifugal machine

An anti-corrosion and wear-resistant, centrifuge technology, used in centrifuges, centrifuges with rotating drums, etc., can solve the problems of accelerated loss of metal components, corrosion of stainless steel components, and large screen wear, etc., to reduce impact and Wear, extended life cycle, extended life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

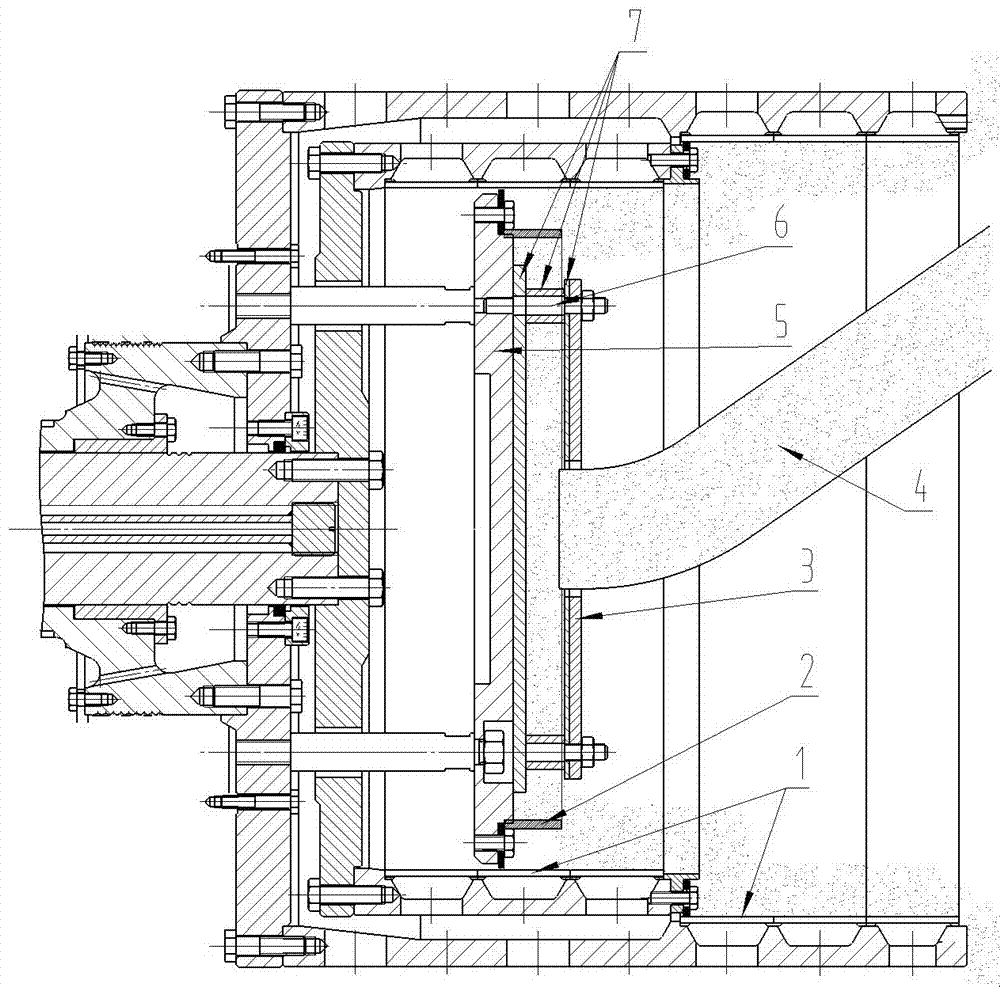

[0016] Such as figure 1 Shown: Lining plastic plates and sleeves on the inner diameter of the feed pipe 4 of the centrifuge, the distribution plate 3, the small support rod 6, the push plate 5 and the wear-resistant ring 2 to form a corrosion-resistant and wear-resistant The non-metallic isolation liner 7;

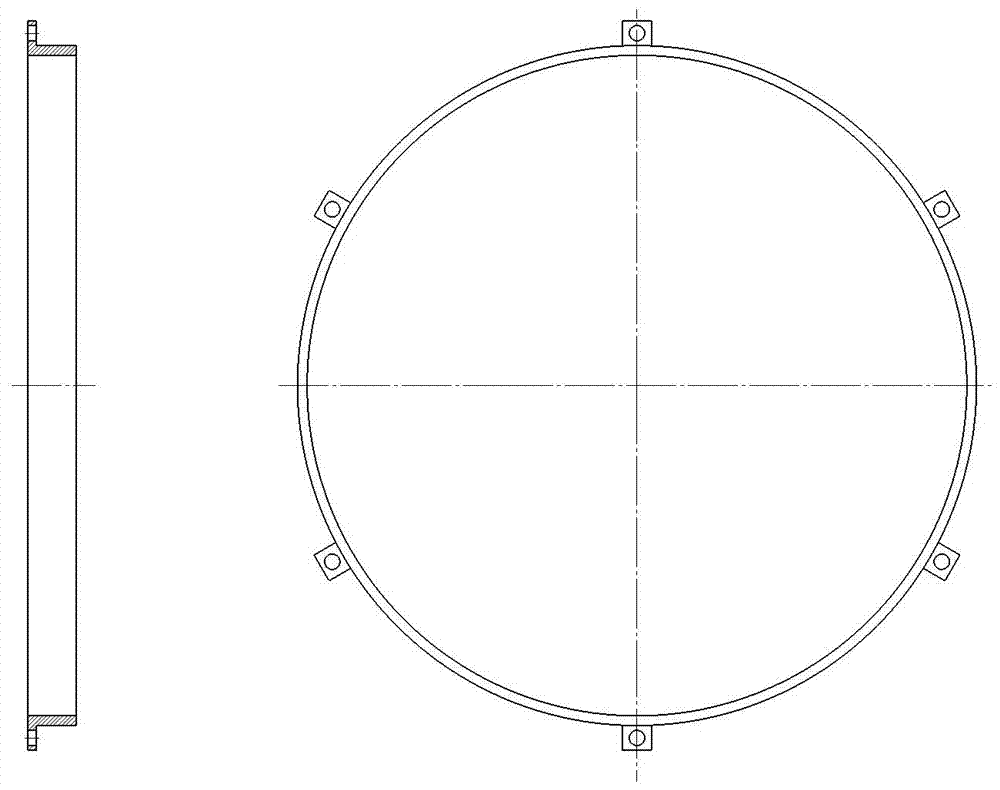

[0017] A wear-resistant ring 2 is arranged on the outer end surface of the pusher plate, and the wear-resistant ring 2 is fixedly connected to the pusher plate 5 by bolts for disassembly and replacement. The wear-resistant ring 2 can avoid the direct impact and wear of the material on the screen ( see figure 2 );

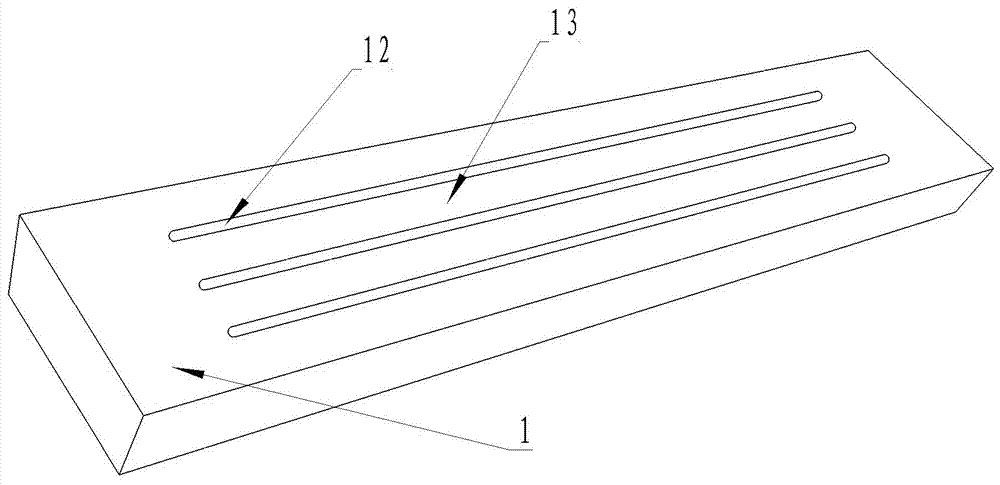

[0018] A wear-resistant ceramic screen is laid on the inner diameter of the drum, and the wear-resistant ceramic screen is composed of several rectangular ceramic filters 1, such as image 3 As shown: each ceramic filter is provided with a number of filter slits 12 and sieve bars 13. When installed, the sieve bars 13 are parallel to the pushing direction, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com