Working method of cutting device for spring machining and with monitoring function

A working method and cutting technology, which is applied in the field of spring production and processing, can solve problems such as the inability to monitor the working status of the cutting device in real time, the inability to ensure long-term efficient and stable operation, and poor work safety, so as to improve the cutting quality and Improve cutting efficiency, improve safety and accuracy, and eliminate sawdust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

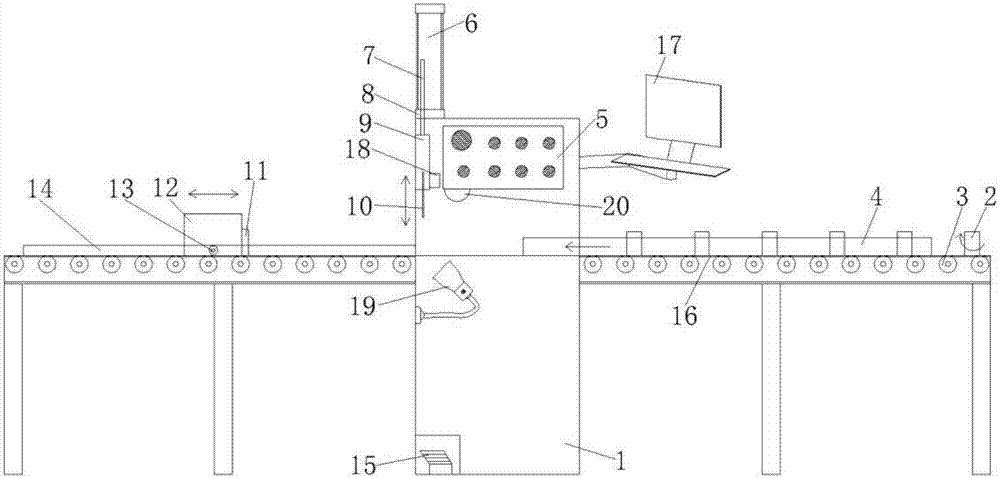

[0025] Such as figure 1 As shown, a kind of working method of the cutting device with monitoring function for spring processing of the present embodiment, the specific working steps are as follows:

[0026] (1) First, loosen the adjusting nut 13 before the operation of the device. By comparing with the scale 14, slide the auxiliary baffle 12 to determine the size required for the workpiece 4. After the size is determined, tighten the adjusting nut 13 to fix the auxiliary baffle. plate 12 and baffle 11;

[0027] (2) Then place the workpiece 4 on the conveyor belt 16 close to the fixed drum 2, and prepare to deliver it forward through the drum 3. At this time, the staff turns on the switch on the control panel 5, according to the material of the workpiece 4, The thickness manually adjusts the cutting speed of the saw blade 10 and the starting height of the pressing plate 9;

[0028] (3) Next, when the head of the workpiece 4 is in contact with the baffle plate 11, the staff co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com