Submerged material cleaning and separating device and method

A technology of separation device and submerged material, which is applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of high cleaning cost and large water consumption of cleaning equipment, and achieve low equipment cost, excellent cleaning and separation effect, The effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

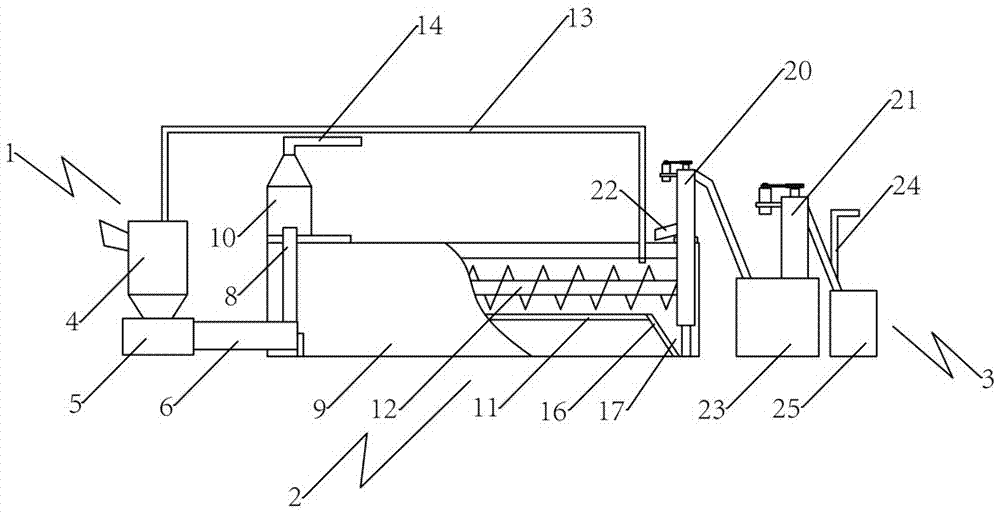

[0027] Embodiment 1: Sinking water material washing and separating device.

[0028] Such as figure 1 Shown, the present invention mainly is made up of parts such as crushing primary washing mechanism 1, kneading type water washing mechanism 2 and dehydration mechanism 3.

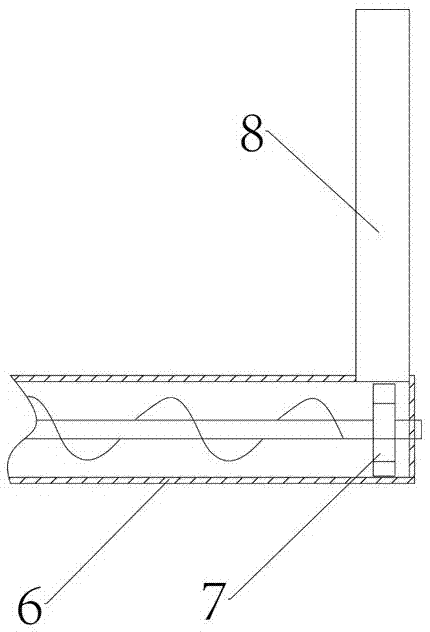

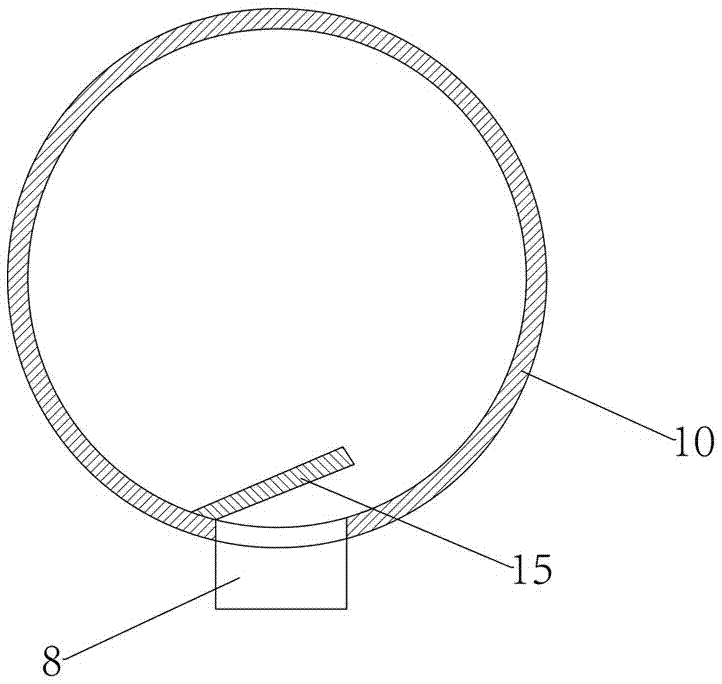

[0029] The crushing primary washing mechanism 1 includes a crushing unit, a spraying unit and a material storage box 5, which are used for crushing and spraying primary washing of worn-out cable materials. The crushing unit includes a crushing bin 4, a rotating shaft arranged in the crushing bin 4 and a number of tool holders arranged on the rotating shaft. The rotating shaft is connected with the crushing driving device. discharge port. The spray unit includes several spray heads arranged on the inner top wall of the crushing bin 4 to spray and initially wash the cable materials being broken in the crushing bin 4 . The material storage box 5 is arranged below the discharge port of the crushing bin 4, and...

Embodiment 2

[0039] Embodiment 2: method for cleaning and separating submerged material.

[0040] The method for cleaning and separating the submerged water material of the present invention comprises the following steps:

[0041] a, a set of sinking water material cleaning and separating device described in embodiment 1 is set, and cleaning water is passed into the pool 9, so that the water surface is not over the conveying screw 12;

[0042] b. Start the crushing initial washing mechanism 1, the rubbing type water washing mechanism 2 and the dehydration mechanism 3, add the waste cable material from the feeding hopper of the crushing unit to the crushing bin 4, and crush it by the knife holder in the crushing bin 4, At the same time, the supernatant from the discharge end of the pool 9 enters the spray head of the spray unit through the supernatant extraction pipe 13, and sprays and initially washes the waste cable materials that are being crushed. During the crushing and spraying proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com