A water-based waste drilling fluid electrochemical adsorption treatment device and its process

A waste drilling fluid and adsorption treatment technology, applied in mining wastewater treatment, water/sewage treatment, water/sewage treatment equipment, etc., can solve problems such as high environmental risk, low resource utilization rate, hidden dangers of soil and groundwater pollution, etc., to achieve Save drilling costs, improve recycling performance, and save the effect of harmless treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

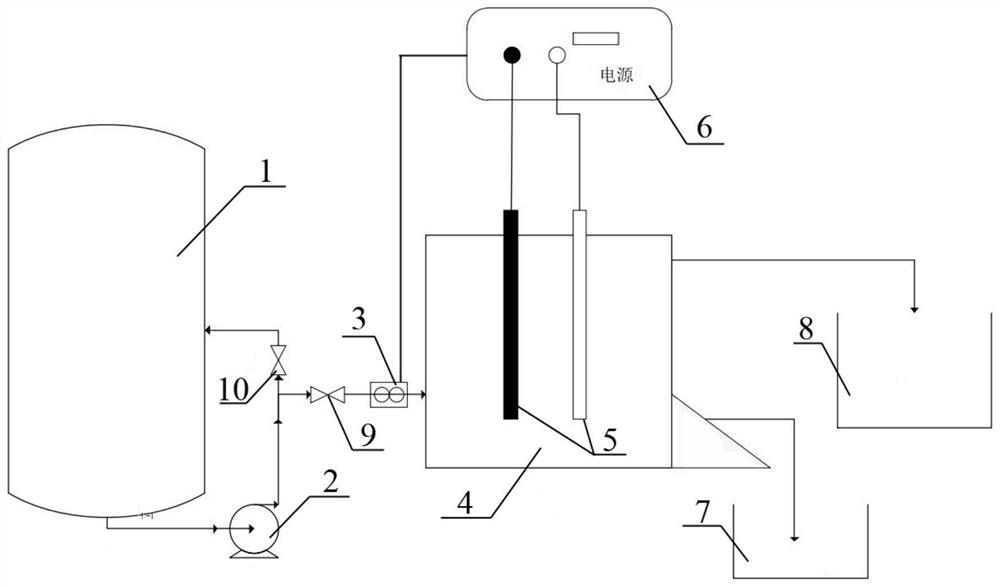

[0036] This embodiment provides a water-based waste drilling fluid electrochemical adsorption treatment device, such as figure 1 As mentioned above, the water-based waste drilling fluid electrochemical adsorption treatment device includes a mud tank 1, a mud pump 2, a flow meter 3, an electrolytic tank 4, an electrode 5, an automatic control system 6, a sludge tank 7, a mud tank 8, and a valve 9 and valve 10;

[0037] The mud tank 1 is in communication with the mud pump 2 and is provided with a valve 10 on the connected pipeline; the mud pump 2 is connected with the flow meter 3 and is provided with a valve 9 on the connected pipeline; the mud tank 1 It communicates with the flow meter 3, and the valve 10 and the valve 9 are sequentially arranged on the connected pipeline; the flow meter 3 communicates with the electrolytic cell 4; the electrode 5 includes an anode and a negative electrode, and the electrode 5 is placed in the electrolytic cell 4 The automatic control system ...

Embodiment 2

[0040]This embodiment provides a water-based waste drilling fluid electrochemical adsorption treatment process, which is carried out by using the water-based waste drilling fluid electrochemical adsorption treatment device provided in Example 1, including the following steps:

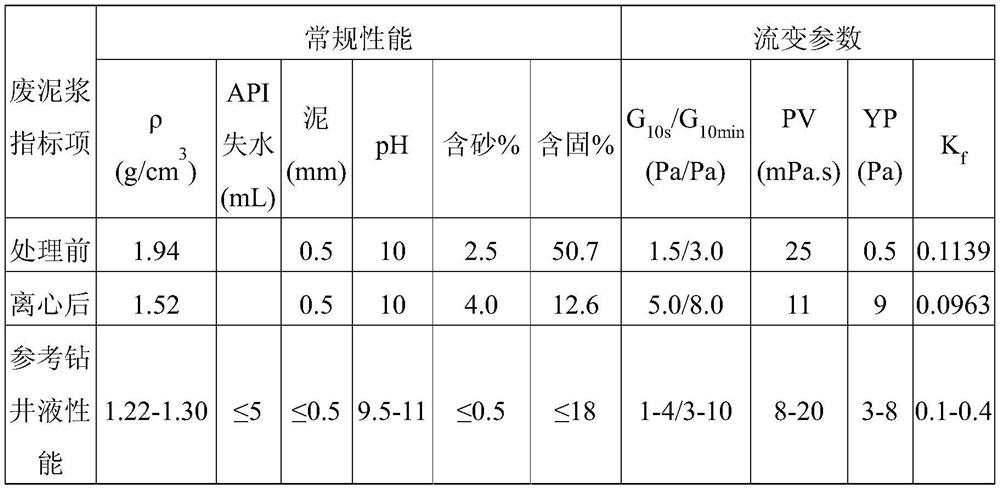

[0041] Utilize the mud pump 2 to pump the drilling fluid after centrifugal treatment (see Table 1 for its parameters) from the mud tank 1 into the electrolytic cell, and adjust the flow rate of the drilling fluid through the automatic control system 6 to adjust the flow meter 3 to be 20L / h. When the drilling fluid flow rate is greater than 20 L / h, the valve 10 is opened, and part of the drilling fluid flows back into the mud tank 1 .

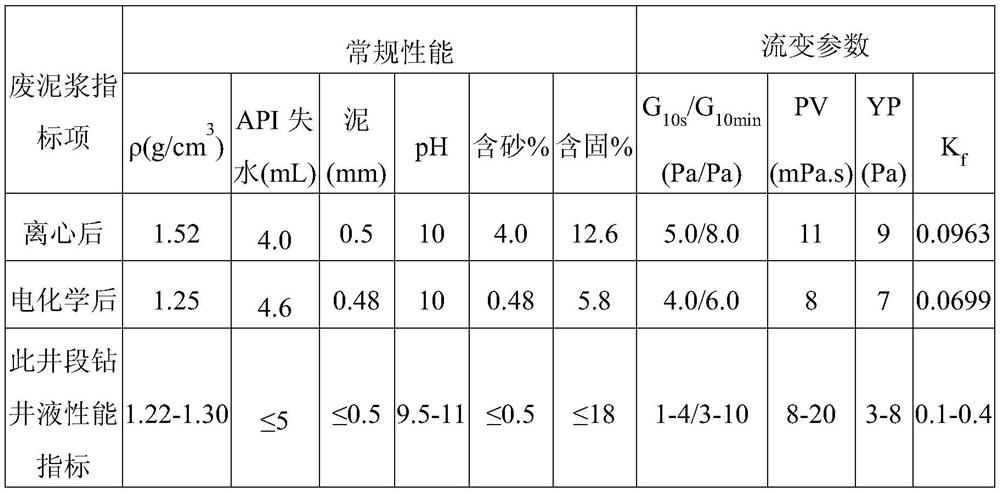

[0042] Then, the electrode is controlled by the automatic control system to carry out electrochemical adsorption, the voltage is adjusted to 10V, and the output current is 2A. The scraper is controlled by the automatic control system to scrape off the solid particles depos...

Embodiment 3

[0048] This embodiment provides a water-based waste drilling fluid electrochemical adsorption treatment process, which is carried out by using the water-based waste drilling fluid electrochemical adsorption treatment device provided in Example 1, including the following steps:

[0049] Utilize the mud pump 2 to pump the drilling fluid after centrifugal treatment (see Table 1 for its parameters) from the mud tank 1 into the electrolytic cell, and adjust the flow rate of the drilling fluid through the automatic control system 6 to adjust the flow meter 3 to be 20L / h. When the drilling fluid flow rate is greater than 20 L / h, the valve 10 is opened, and part of the drilling fluid flows back into the mud tank 1 .

[0050] Then, the electrode is controlled by the automatic control system for electrochemical adsorption, the voltage is adjusted to 15V, and the output current is 4A. The scraper is controlled by the automatic control system to scrape off the solid particles deposited on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com