Ceramsite coating with iron ore as main raw material

A main raw material, iron ore technology, used in ceramic products, applications, household appliances, etc., can solve the problems of easy peeling and decolorization of the color layer, high cost of color materials, and achieve the effect of low cost, low cost and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

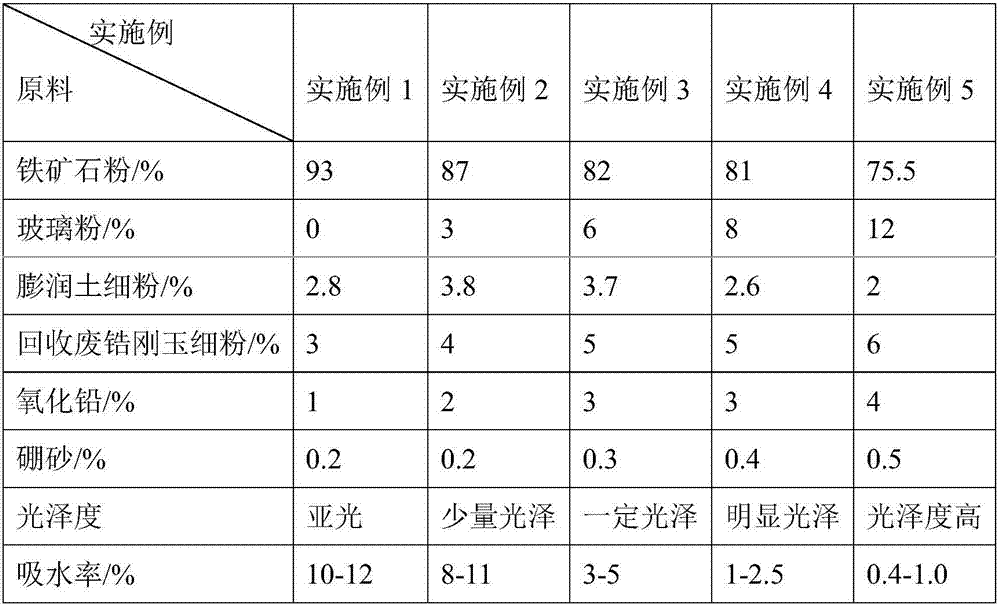

Embodiment 1

[0027] A matt ceramsite coating with iron ore as the main raw material, the raw material composition includes: 93% iron ore powder with a particle size not greater than 0.1mm, 2.8% bentonite fine powder with a particle size not greater than 0.088mm; Recycled waste zirconium corundum fine powder not larger than 0.088mm 3%; lead oxide 1%; borax 0.2%. Among them, the main component of iron ore powder is magnetite, and the powder with a particle size of not more than 0.088mm accounts for 42%; the content of zirconium dioxide in the recovered waste zirconium corundum fine powder is 12.1%.

[0028] The application method of the above-mentioned ceramsite coating with iron ore as the main raw material: After the raw materials of the above-mentioned ceramsite coating with iron ore as the main raw material are mixed evenly, add them to the disc granulator and roll together with the wet ceramsite raw balls 3 minutes, while spraying clean water and mist, the surface of the ceramsite can b...

Embodiment 2

[0031] A bright ceramsite paint with iron ore as the main raw material, its raw material composition includes: 87% iron ore powder with a particle size not greater than 0.1mm; lead-containing low-melting glass powder (D245 ) 3%, bentonite fine powder with a particle size not greater than 0.088mm 3.8%; recycled waste zirconium corundum fine powder with a particle size not greater than 0.088mm 4%; lead oxide 2%; borax 0.2%; wherein, the iron ore powder used is mainly composed of Magnetite, fine powder with a particle size not greater than 0.088mm accounts for 51%; the content of zirconium dioxide in the recovered waste zirconium corundum fine powder is 15.4%.

[0032] The application method of the above-mentioned ceramsite coating with iron ore as the main raw material: After the raw materials of the above-mentioned ceramsite coating with iron ore as the main raw material are mixed evenly, add them to the disc granulator and roll together with the wet ceramsite raw balls For 2 m...

Embodiment 3

[0035] A bright ceramsite paint with iron ore as the main raw material, its raw material composition includes: 82% iron ore powder with a particle size not greater than 0.1mm; lead-free low-melting glass powder with a particle size not greater than 0.1mm (D250 ) 6%, bentonite fine powder with a particle size not greater than 0.088mm 3.7%; recycled waste zirconium corundum fine powder with a particle size not greater than 0.088mm 5%; lead oxide 3%; borax 0.3%. Among them, the main component of iron ore powder is magnetite, and the fine powder material with a particle size not greater than 0.088mm accounts for 57%; the content of zirconium dioxide in the recovered waste zirconium corundum fine powder is 18.2%.

[0036] The application method of the above-mentioned ceramsite coating with iron ore as the main raw material: After the raw materials of the above-mentioned ceramsite coating with iron ore as the main raw material are mixed evenly, add them to the disc granulator and rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com