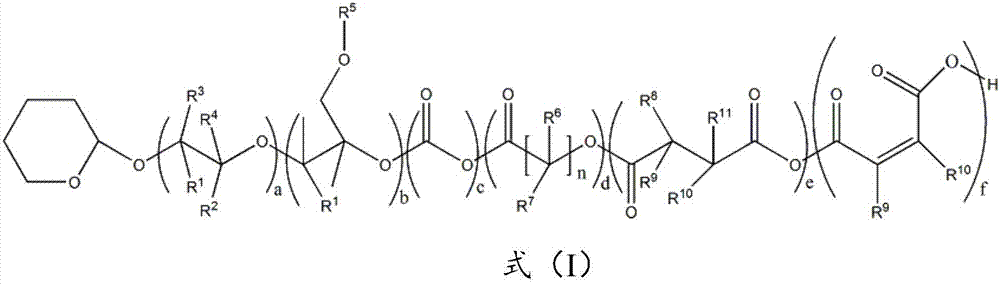

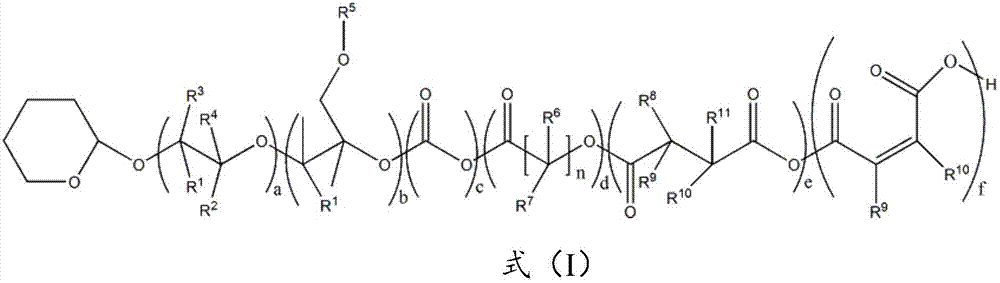

Silane blocking resin containing urethane group and preparation method of silane blocking resin

A urethane-based, silane-terminated technology, used in the field of silane-modified resins, can solve the problems of single molecular weight distribution, reduced mechanical properties, and high resin viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] The preparation process of the silane-terminated polyurethane resin containing carbamate is as follows:

[0095] Add 500g of HOROTHP (62.5mmol) and 7.0g of IPDI (31.8mmol) with a number average molecular weight of 8000 into a 2L three-necked flask, preheat to 60-70°C while stirring, add 0.1g of stannous octoate °C until the NCO content in the system is lower than 0.05%. Then add 500ml of methanol and 0.5g of Amberlyst H-15 solid acid loaded on silica gel, react at 45°C for 2h, filter out the solid acid catalyst, and remove the solvent by heating in vacuo. In the product obtained, add 13.0g 3-isocyanatopropyltrimethoxysilane (62.5mmol), 0.1g stannous octoate catalyst, stir and react to the NCO content in the system below 0.05% at 70 ℃, promptly obtain viscosity 16500cP urethane-containing silane-terminated polyurethane resin.

[0096] The urethane-containing silane-terminated polyurethane resin prepared above was cast into a film with a thickness of 2 mm, and cured for...

Embodiment 2

[0098] The preparation process of the silane-terminated polyurethane resin containing carbamate is as follows:

[0099] Add 500g of HOROTHP (41.7mmol) with a number average molecular weight of 12000 and 4.8g of IPDI (21mmol) into a 2L three-necked flask, preheat it to 60-70°C while stirring, add 0.1g of stannous octoate catalyst, and set the temperature at 70°C React until the NCO content in the system is lower than 0.05%. Then add 500ml of methanol and 0.5g of Amberlyst H-15 solid acid loaded on silica gel, react at 45°C for 2h, filter out the solid acid catalyst, and remove the solvent by heating in vacuo. Add 8.6g 3-isocyanatopropyl trimethoxysilane (42mmol) in the product obtained, 0.05g stannous octoate catalyst, stir and react at 70 ℃ until the NCO content in the system is lower than 0.05%, and the obtained viscosity is 21000cP A urethane-containing silane-terminated polyurethane resin.

[0100] The urethane-containing silane-terminated polyurethane resin prepared abov...

Embodiment 3

[0102] The preparation process of the silane-terminated polyurethane resin containing carbamate is as follows:

[0103] Add 500g of HOROTHP (62.5mmol) and 7.0g of IPDI (31.8mmol) with a number average molecular weight of 8000 into a 2L three-necked flask, preheat to 60-70°C while stirring, add 0.1g of stannous octoate °C until the NCO content in the system is lower than 0.05%. Then add 500ml of methanol and 0.5g of Amberlyst H-15 solid acid loaded on silica gel, react at 45°C for 2h, filter out the solid acid catalyst, and remove the solvent by heating in vacuo. Add 14.0g IPDI (62.5mmol) and 0.1g stannous octoate catalyst to the obtained product, stir and react at 70°C for 3h, then add 16.0g (62.5mmol) anilinopropyltrimethoxysilane to obtain a viscosity of 18000cP A urethane-containing silane-terminated polyurethane resin.

[0104] The urethane-containing silane-terminated polyurethane resin prepared above was cast into a film with a thickness of 2 mm, and cured for 14 days ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com