A kind of β-galactose modified nitric oxide sustained-release hydrogel and its preparation method and application

A technology of nitric oxide and galactose, which is applied in the field of biomedical engineering, can solve problems such as applications that have not yet been reported, and achieve the effects of excellent physical and chemical properties, clear polymer structure, and easy structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

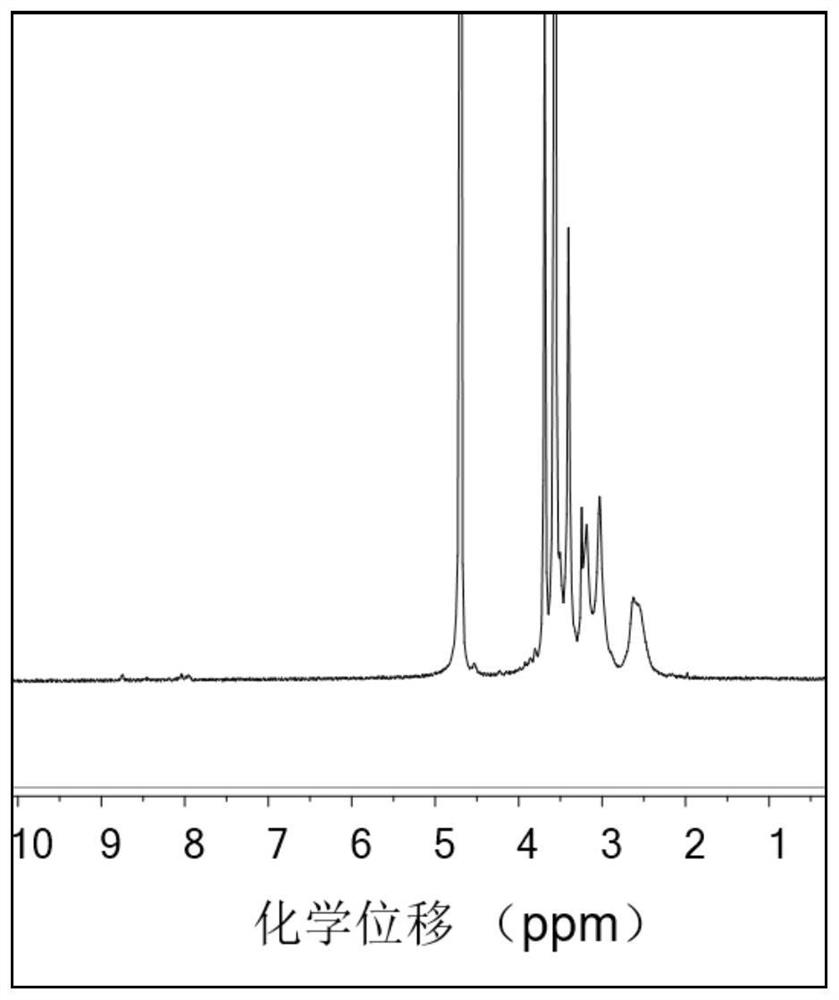

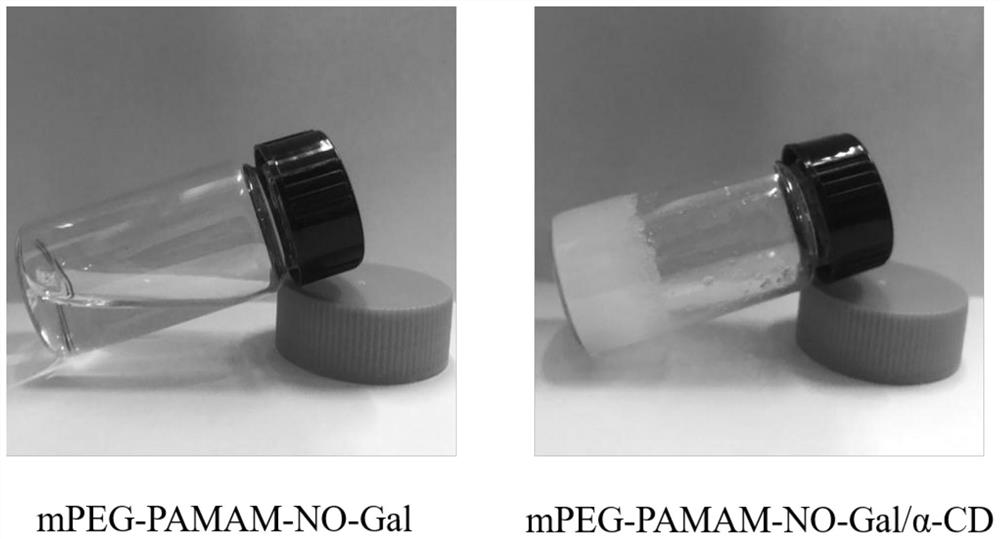

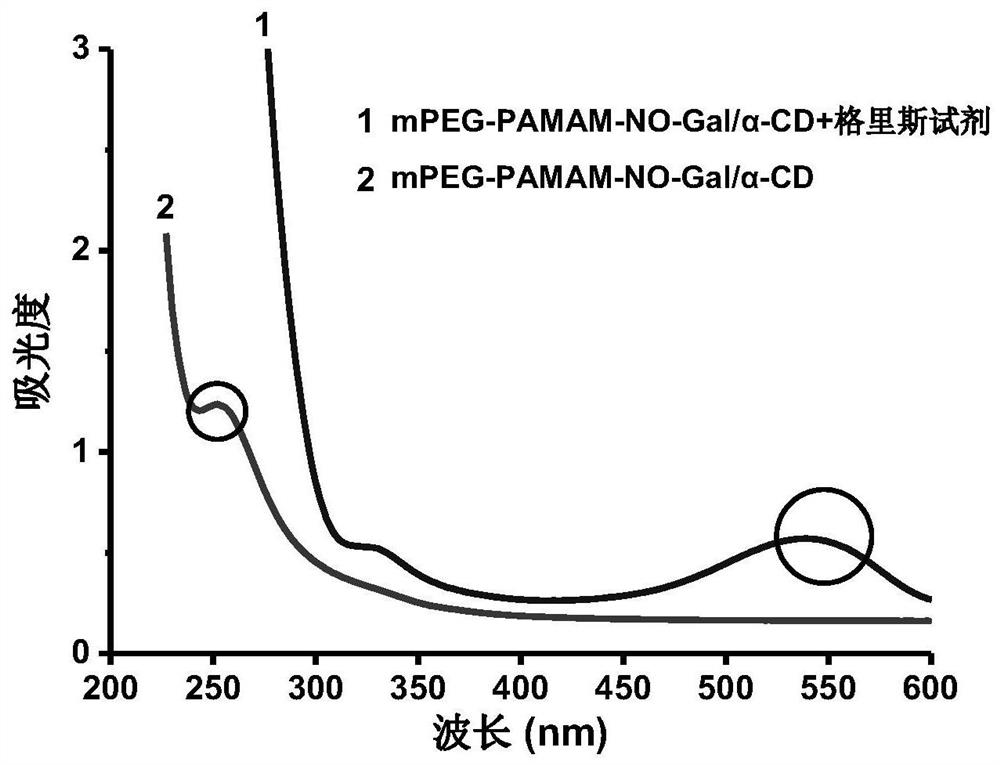

[0064] (1) Synthesis of PAMAM (PAMAM-NO) loaded with nitric oxide

[0065] Synthesis of Polyamide Dendrimers Containing Alkyne Groups (PAMAM)

[0066] Referring to the preparation method of Example 4 in the patent (Application No. 201610356643.9, a cationic polymer loaded with nitric oxide and its preparation method and application), an alkyne-containing polyamide dendrimer was prepared.

[0067] PAMAM and CH 3 ONa dissolved in CH 3 OH, PAMAM and CH 3 The molar ratio of ONa is 1:200; CH 3 The dosage of OH is to dissolve 0.1g CH per 10mL 3 ONa meter, after stabilizing for 10 minutes, place it in a high-pressure reactor and seal it, feed high-purity nitrogen for 5 minutes and maintain the pressure of the reactor at 10 psi, remove the air in the reactor, then feed NO gas (40 psi), and react at room temperature for 3 sky. After the reaction is over, feed high-purity nitrogen gas (10psi) for 10 minutes to discharge unreacted NO, open the reaction vessel, and take out the reac...

Embodiment 2

[0077] (1) Synthesis of PAMAM (PAMAM-NO) loaded with nitric oxide

[0078]Synthesis of Polyamide Dendrimers Containing Alkyne Groups (PAMAM)

[0079] Referring to the preparation method of Example 5 in the patent (Application No. 201610356643.9, a cationic polymer loaded with nitric oxide and its preparation method and application), an alkyne-containing polyamide dendrimer was prepared.

[0080] PAMAM and CH 3 ONa dissolved in CH 3 OH, PAMAM and CH 3 The molar ratio of ONa is 1:300; CH 3 The dosage of OH is to dissolve 0.3g CH per 10mL 3 ONa meter, stabilized for 30 minutes, placed in a high-pressure reactor and sealed, fed high-purity nitrogen for 15 minutes and maintained the pressure of the reactor at 20 psi, removed the air in the reactor, and then fed NO gas (80 psi), and reacted at room temperature for 7 days . After the reaction is over, feed high-purity nitrogen gas (20psi) for 20 minutes to discharge unreacted NO, open the reactor, and take out the reaction prod...

Embodiment 3

[0090] (1) Synthesis of PAMAM (PAMAM-NO) loaded with nitric oxide

[0091] Synthesis of Polyamide Dendrimers Containing Alkyne Groups (PAMAM)

[0092] Referring to the preparation method of Example 6 in the patent (Application No. 201610356643.9, a cationic polymer loaded with nitric oxide and its preparation method and application), an alkyne-containing polyamide dendrimer was prepared.

[0093] PAMAM and CH 3 ONa dissolved in CH 3 OH, PAMAM and CH 3 The molar ratio of ONa is 1:500; CH 3 The dosage of OH is to dissolve 0.5g CH per 10mL 3 ONa meter, after stabilizing for 20min, place it in a high-pressure reactor and seal it, feed high-purity nitrogen for 10min and maintain the pressure of the reactor at 15psi, remove the air in the reactor, then feed NO gas (80psi), and react at room temperature for 5 sky. After the reaction is over, feed high-purity nitrogen gas (15psi) for 15 minutes to discharge unreacted NO, open the reaction vessel, and take out the reaction produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com