Anti-rollover building demolishing machine with protective frames

A protective frame and anti-rollover technology, which is applied in construction, building maintenance, building construction, etc., can solve the problems of high labor intensity, long construction period, environmental pollution, etc., and achieve the effect of avoiding rollover accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

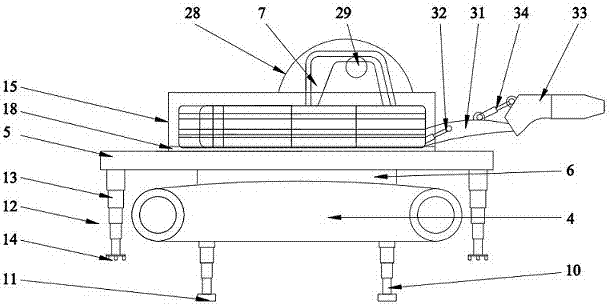

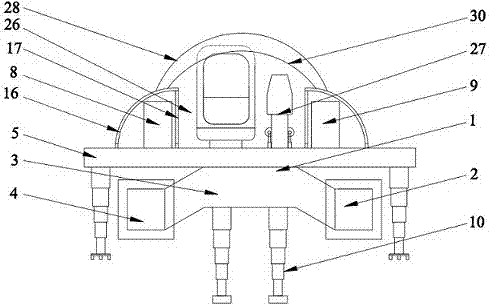

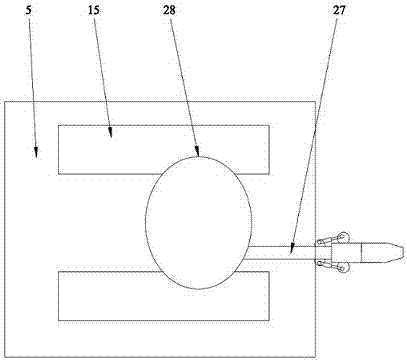

[0022] An anti-rollover building demolition machine with a protective frame, including a traveling device and an upper turntable, the traveling device includes a lower frame (1), the lower frame (1) is provided with a left crawler frame (2), a main frame (3 ) and the right crawler frame (4), the upper turntable includes the upper frame (5), the upper frame (5) is connected with the lower frame (1) through the slewing bearing (6), and the upper frame (5) is equipped with Driver's cab (7), hydraulic transmission device (8) and power unit (9). The hydraulic transmission device includes hydraulic tanks, hydraulic pumps, control valves, pipelines and other components. Power devices such as engines, hydraulic transmission devices and power units are Existing technology, without repeating its details, is characterized in that: the lower end surface of the main frame (3) close to the two sides of the left track frame (2) and the right track frame (4) are respectively provided with two ...

Embodiment 2

[0024]An anti-rollover building demolition machine with a protective frame, including a traveling device and an upper turntable, the traveling device includes a lower frame (1), the lower frame (1) is provided with a left crawler frame (2), a main frame (3 ) and the right crawler frame (4), the upper turntable includes the upper frame (5), the upper frame (5) is connected with the lower frame (1) through the slewing bearing (6), and the upper frame (5) is equipped with Driver's cab (7), hydraulic transmission device (8) and power unit (9). The hydraulic transmission device includes hydraulic oil tanks, hydraulic pumps, control valves, pipelines and other components. Power devices such as engines, hydraulic transmission devices and power devices belong to Existing technology, without repeating its details, is characterized in that: the lower end surface of the main frame (3) close to the two sides of the left track frame (2) and the right track frame (4) are respectively provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com